Metkey Rice Color Sorter provides a high-precision rice sorting solution for all types of rice. Whether it’s freshly harvested rice or long-term storage rice in the warehouse, it is impossible to avoid problems of lesions, impurities, breakage, even moldy rice.

These problems are also threatening our food safety at all times. Metkey Rice Color Sorter is designed to separate fine rice from the original rice materials, which will greatly improve your production efficiency.

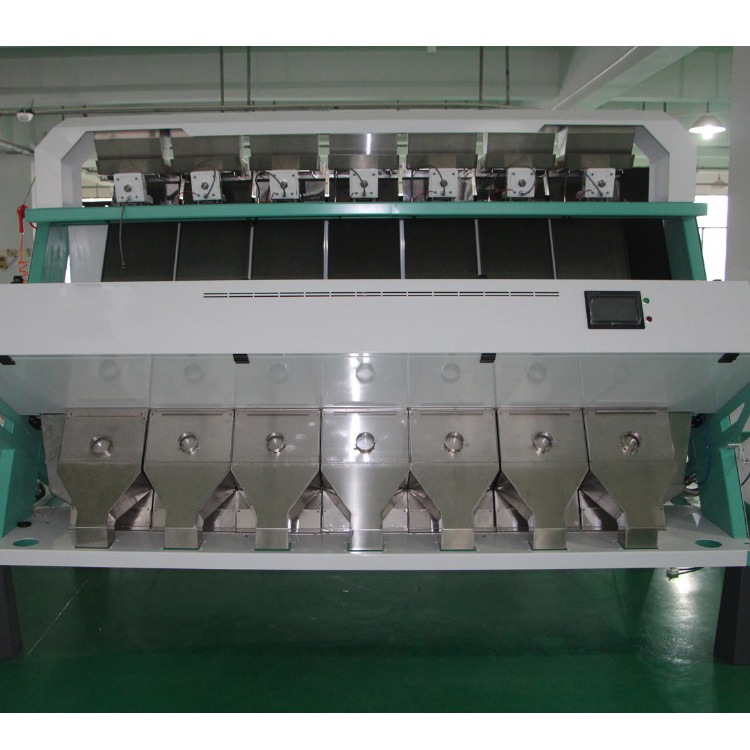

METKEY RICE COLOR SORTER WITH DIFFERENT CHUTES

|

Model

|

SIZE(MM)

|

POWER(KW)

|

Output (T/H)

(take ≤2% polished round-grained rice as an example)

|

Sorting accuracy

(%)

|

Micro yellow recognition

accuracy(%)

|

Chalky recognition

accuracy(%)

|

Ratio of color

separation mass(%)

|

WEIGHT(KG)

|

|

MRCS-126S

|

1244*1504*2090

|

1.5

|

2.0-6.0

|

≥99.99

|

98

|

98

|

>80:1

|

614

|

|

MRCS-189S

|

1558*1504*2090

|

2.2

|

4.0-9.0

|

≥99.99

|

98

|

98

|

>80:1

|

789

|

|

MRCS-252S

|

1872*1504*2090

|

2.9

|

5.0-12.0

|

≥99.99

|

98

|

98

|

>80:1

|

834

|

|

MRCS-315S

|

2186*1504*2090

|

3.6

|

6.0-15.0

|

≥99.99

|

98

|

98

|

>80:1

|

1052

|

|

MRCS-378S

|

2500*1504*2090

|

4.3

|

7.0-18.0

|

≥99.99

|

98

|

98

|

>80:1

|

1265

|

|

MRCS-441S

|

2814*1504*2090

|

4.9

|

9.0-21.0

|

≥99.99

|

98

|

98

|

>80:1

|

1457

|

|

MRCS-504S

|

3128*1504*2090

|

5.6

|

10.0-24.0

|

≥99.99

|

98

|

98

|

>80:1

|

1637

|

|

MRCS-630S

|

3756*1504*2090

|

7.0

|

11.0-30.0

|

≥99.99

|

98

|

98

|

>80:1

|

2018

|

Metkey Rice Color Sorter Offers a high accuracy and fast optical sorting solution to all types of rice. It will greatly improve the quality of the rice

Removes Moldy Seeds, Shells and Other Strong-headed Impurities like Sand, Glass Through Color Difference;

Separate rice Into Many Categories Based On Sizes, Shapes, and Colors;

Custom Different Sorting Capability To Meet Your Requirements;

Business Starts From 1 Unit, Ship Directly To Your Hand.

Big Advantage with Metkey Rice Color Sorter

1.Cloud Interconnection System

Thanks to cloud service technical platform, remote control, operation, maintenance, software upgrade can be achieved and it can detect and solve the LED light, electronic,mechanical and adjustment problems.It also can provide real-time online tracking service for the machine operation monitoring,data acquisition and online instruction.

2.One Key Intelligent Operation System

The users can set the area of the material color, shape, size and defect by themselves and confirm the rejected material,so the machine can automatic set the sorting solution of the material according to the independent calculating, intelligent recognition and intelligent sorting principles with one key intelligent control technology.

3.Intelligent Visual Image Capture System

It can realize the visual dynamic image capture system by adopting the high resolution full color CCD sensor and beg eye low distortion lens.

4.Intelligent LED Light Control System

It can adjust the brightness of the LED automatically according to the material sorting requirements and environment changing due to advanced digital stepless automatic LED light adjustment technology. The best sorting performance will be achieved.

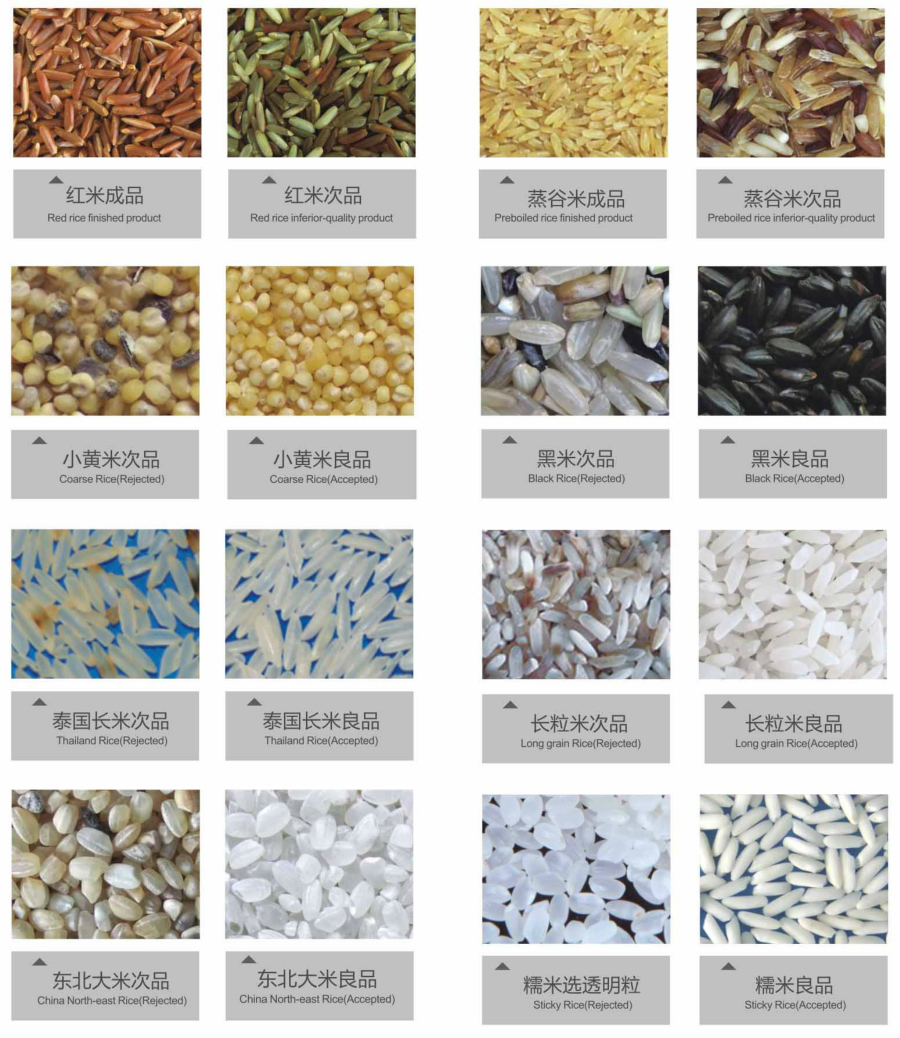

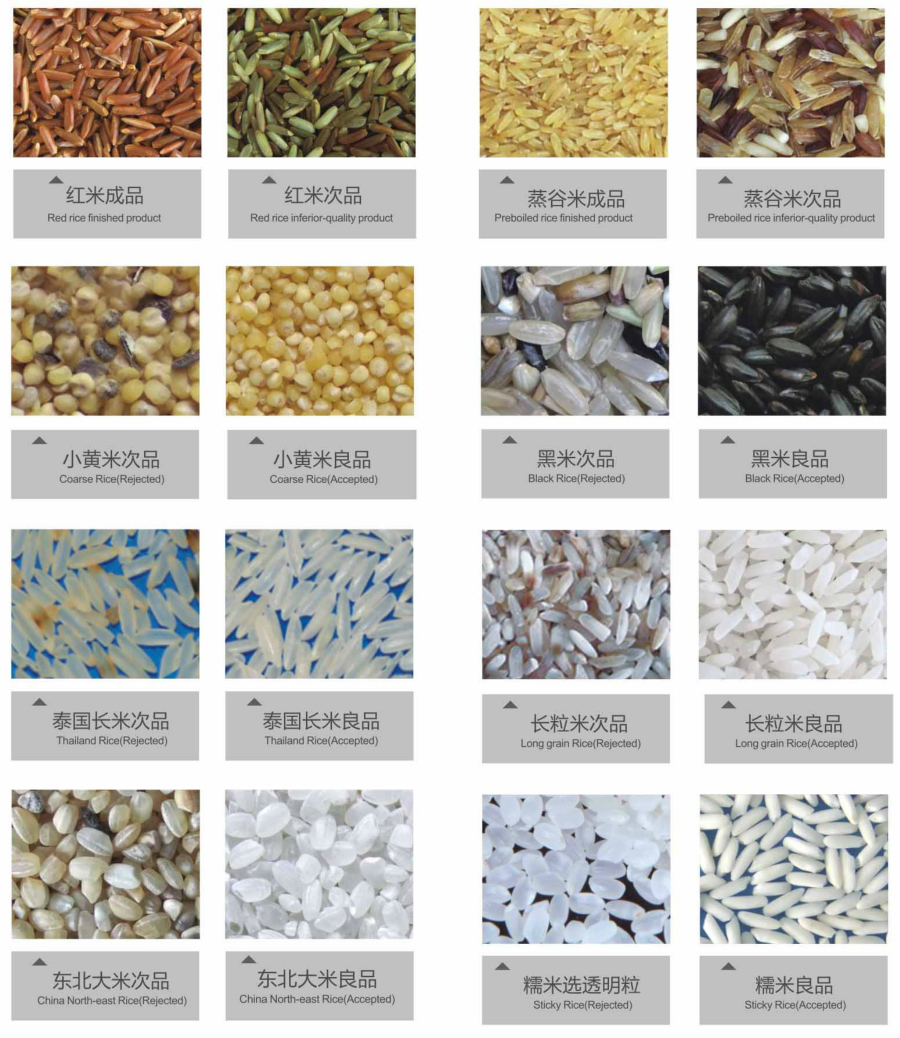

Examples of Sorting

METKEY Rice Color Sorter is not only used for regular rice like long-shaped rice, round-shaped rice, and sticky rice, but it is also used for other types of rice such as black rice, yellow rice, rose rice, and even high glutinous rice. The sorting accuracy at one time is close to 99.9% and a single chute sorting capacity is less than 1.3 ton per hour.

Sorting Result with METKEY Rice Color Sorter

How Does METKEY Rice Color Sorter Work

Rice processing begins in a milling plant, where the harvested grains run through a production line where the paddy is boiled, dried, de-stoned, husked, hulled and shelled into rice. It then is taken to the color sorter machine. At this point, the rice mixture will travel by elevator belt into a hopper on top of the machine, from which it will flow down along chutes in the colour sorter, streamlining their flow to so that they may be scanned by CCD sensors. The moment the camera detects any color defects, the camera instructs ejectors fitted in the machine to open the nozzle. The nozzle is connected to valves containing compressed air. This air is then used to shoot out the color defected material from the input rice. The types of defects in rice include black tipped, chalky, yellow, mouse droppings, immature grain, etc.

Product Show

As a professional supplier of optical sorting solutions, we have already served more than 1,000+ different customers all around the world. From small farms to large rice processing factories, we always offer the best equipment solutions at competitive prices.