These problems are also threatening our food safety at all times. METKEY Rice Optical Sorting Machine is designed to separate fine rice from the original rice materials, which will greatly improve your production efficiency.

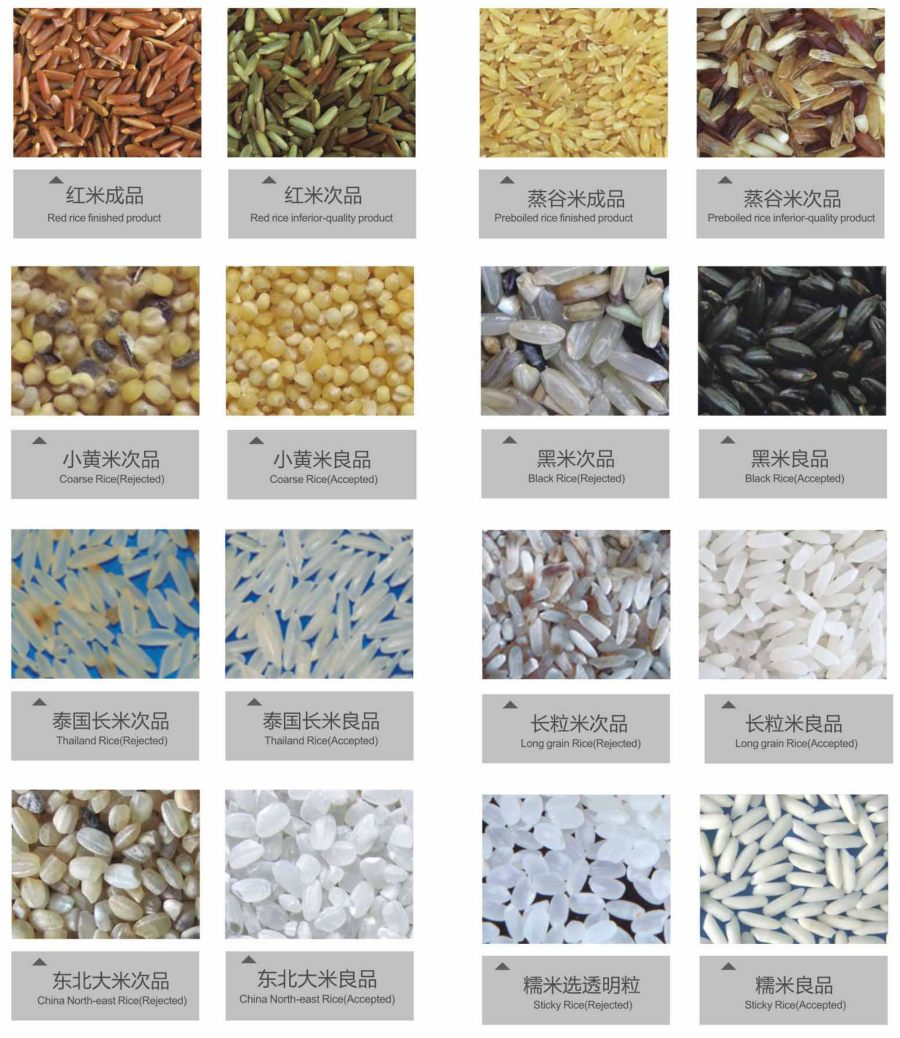

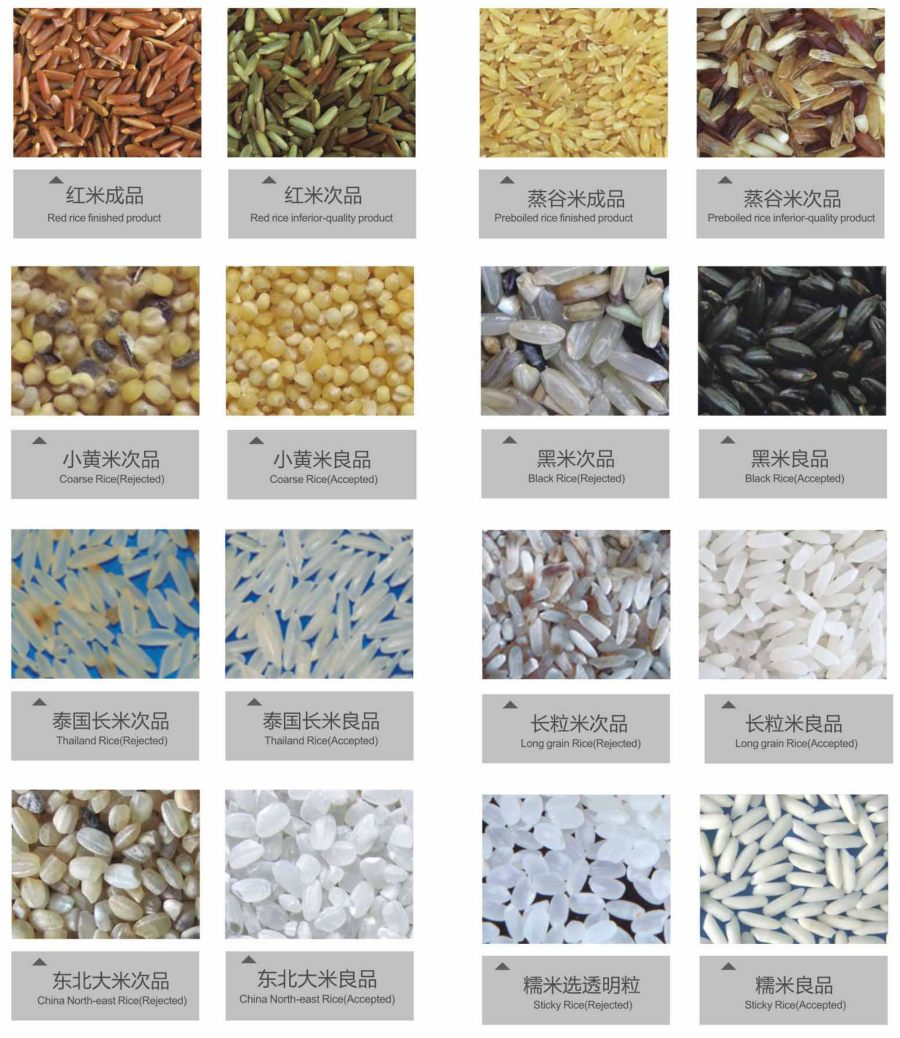

METKEY Rice Optical Sorting Machineis not only used for regular rice like long-shaped rice, round-shaped rice, and sticky rice, but it is also used for other types of rice such as black rice, yellow rice, rose rice, and even high glutinous rice. The sorting accuracy at one time is close to 99.9% and a single chute sorting capacity is less than 1.3 ton per hour.

Advantages of Rice Optical Sorting Machine

Improving Quality

Color sorting machines have revolutionized the quality of food products in a big way. Through a color sorter machine, a manufacturer can monitor the quality of products quickly, and hence launch only high-quality products in the market.

Fast Speed

Color sorter machines are automated, and hence do not retard the rate of quality check. This machine speeds up the entire quality assurance process by getting rid of personal effects like strikes and fatigue.

Control

An operator can decide and change the extent of texture and color difference that a color sorter machine should reject. This is an added control over products, as items can be sorted into multiple categories.

Return on Investment (ROI)

A color-sorting machine gives the investor an incredible ROI. These machines are almost a one-time investment that needs low maintenance.

Labor

Just like any other automated machine, rice color sorters reduce management issues and labor costs. They also minimize the accepted error margin associated with human errors to a vast extent.

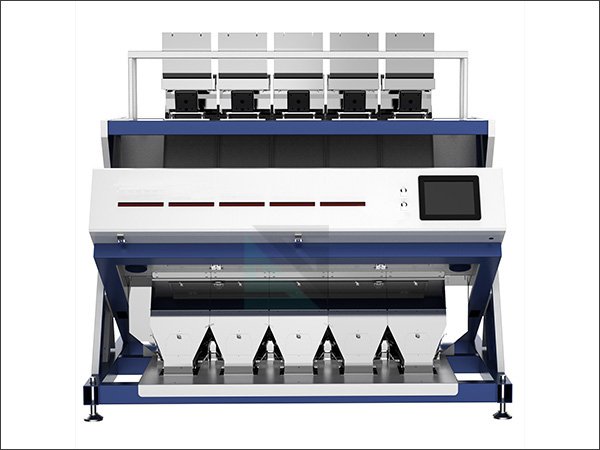

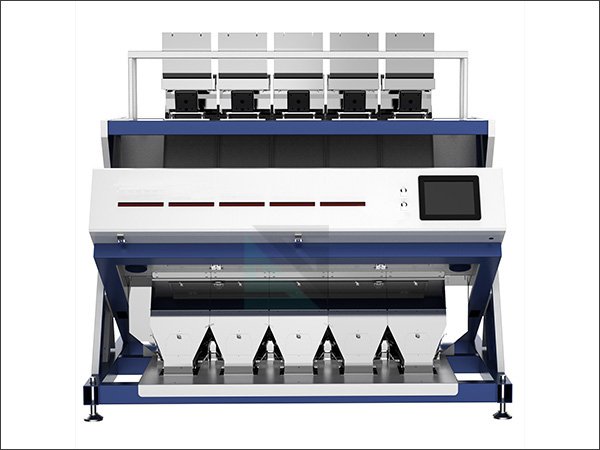

Main Parts of Rice Optical Sorting Machine

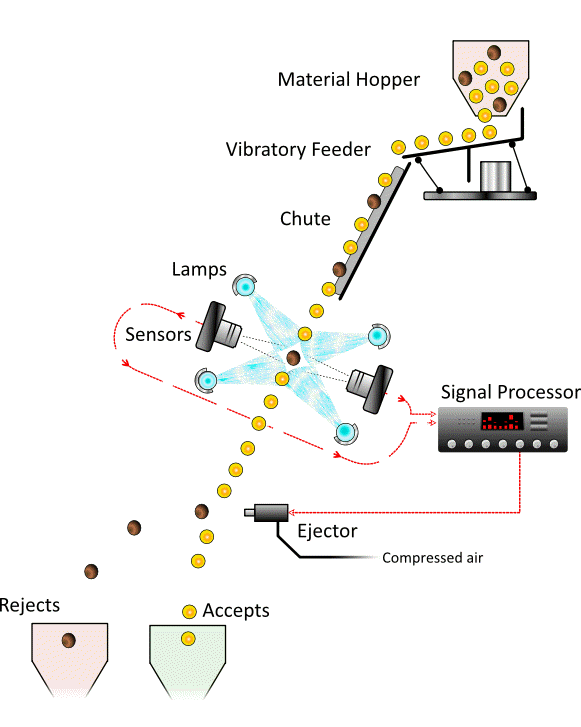

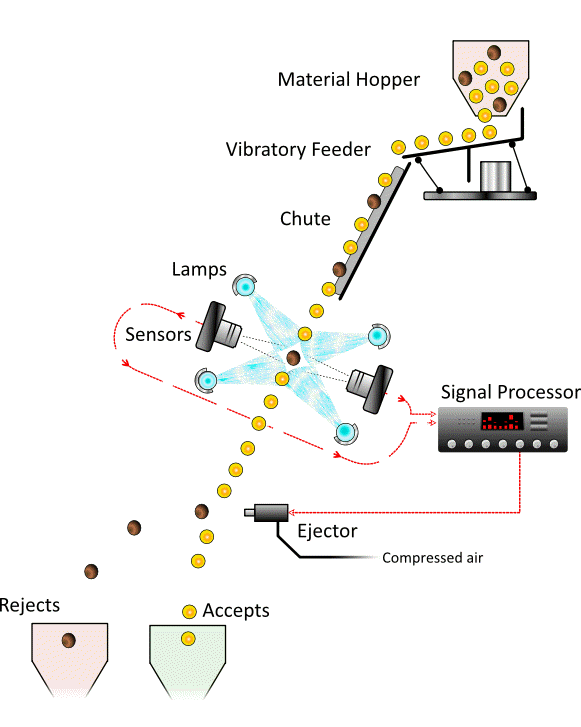

Rice Optical Sorting Machine is made of different components, including the feeding hopper, vibrating feeder, background plate, chute slide, silos, detection camera, air compressors, air nozzle, purifiers, and fillers. Today, Let’s take a look at the machine from four typical systems.

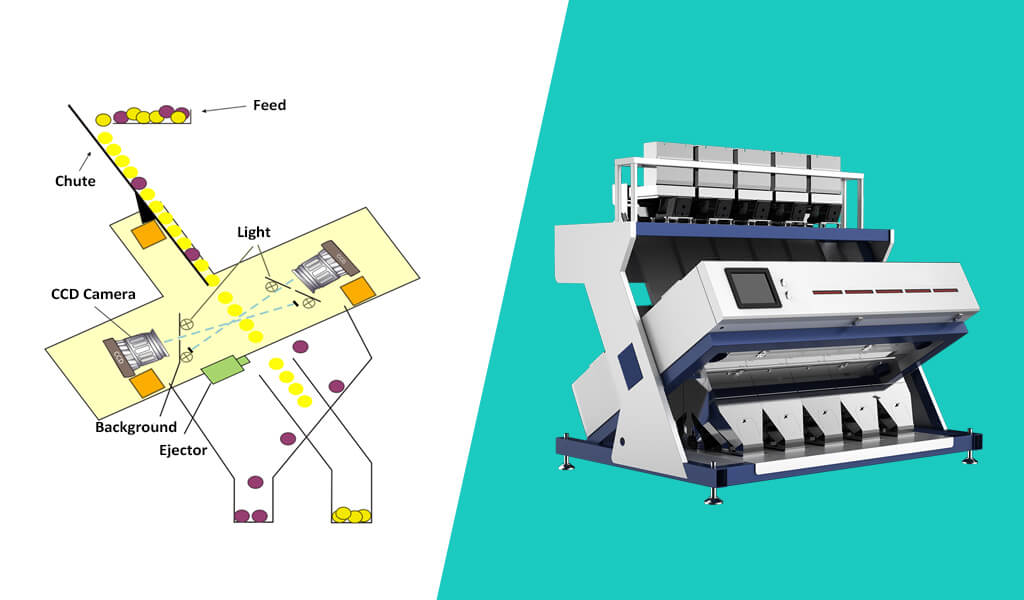

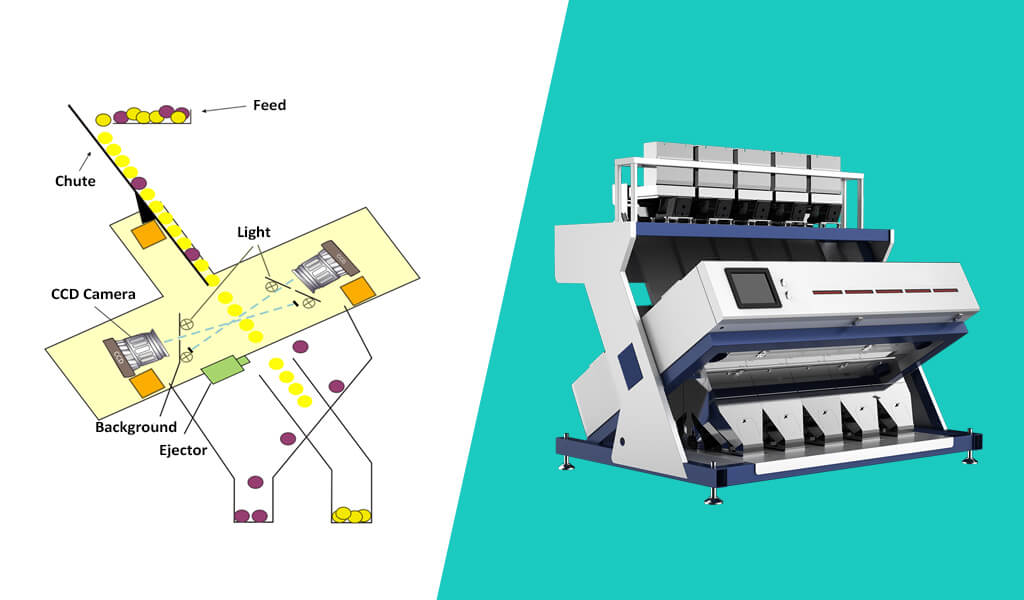

Graphic: Rice Optical Sorting Machine Structure

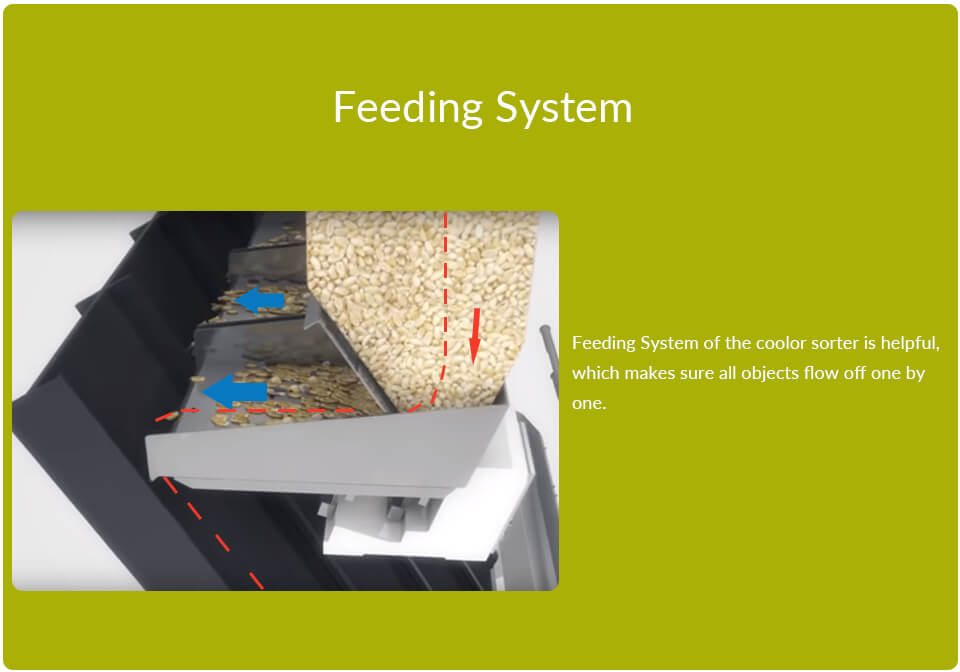

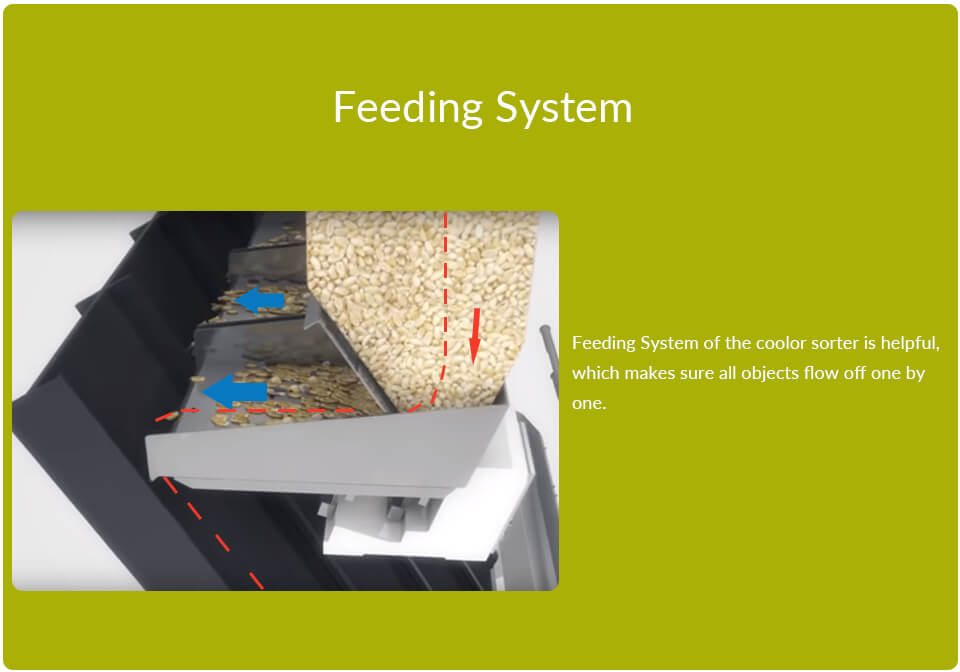

The feeding system is comprised of the hopper, the vibrating feeder, and the chute slide, among other components. The rice meant to be sorted moves from the hopper into the vibratory feeders.

These vibratory feeders are arranged in a manner that enables the material to row in continuous filaments automatically.

After accelerating on a steady speed through the chute, rice falls into the photoelectric detection sorting areas as well as sorting spray zones.

Graphic: Feeding System

The amount of vibration can be controlled within the color sorter unit time production control. Air humidity might affect the rates of air sliding along each other hence affecting the accuracy of rice color selection. At times, there is a need for sorter restoration by inducing suitable temperature levels of drying functions.

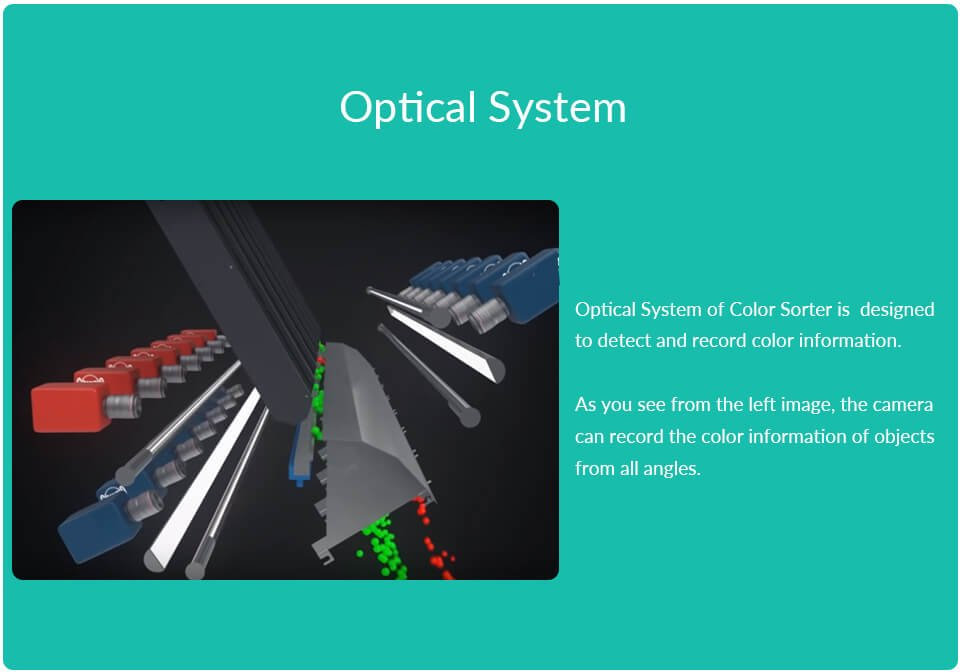

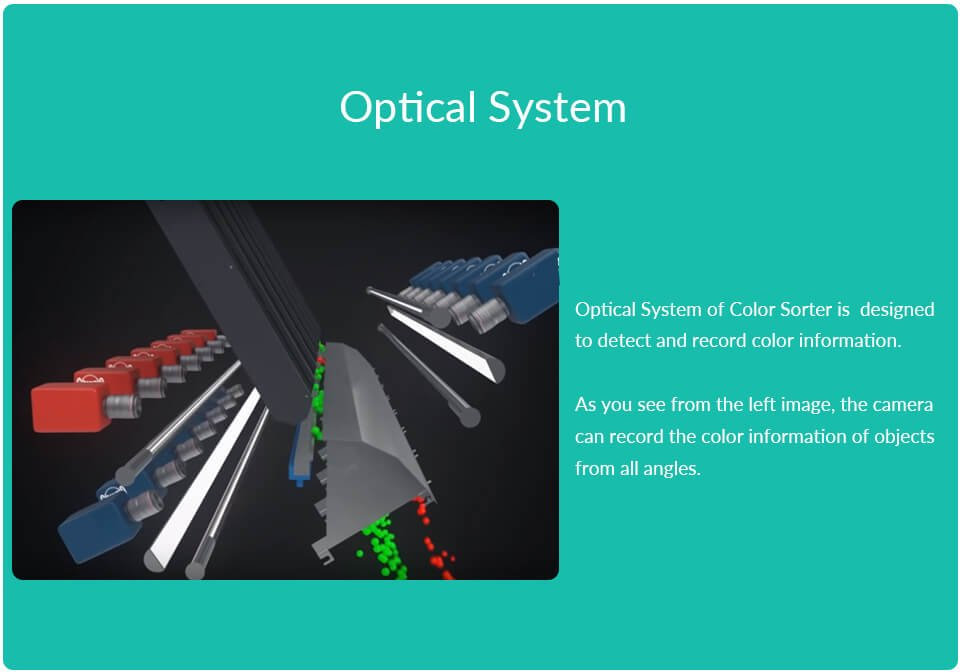

This is the core part of the color sorting machine. It is the source of light, a background plate, the CCD camera, as well as crucial related auxiliary equipment components. The optical system offers uniform illumination on the rice being tested and the background plate.

Research proves that LED light works best in sorting out the rice.

The detection area within test materials reflects light into electric signals. The CCD camera detection is sealed so as to prevent stray light from getting into the CCD camera, as this would compromise quality.

Graphic: Optical System

There is a broad background of an electronic control system meant to provide a reference signal. The optical system has reflective characteristics and reflective properties to substantially differentiate the quality products from the rest.

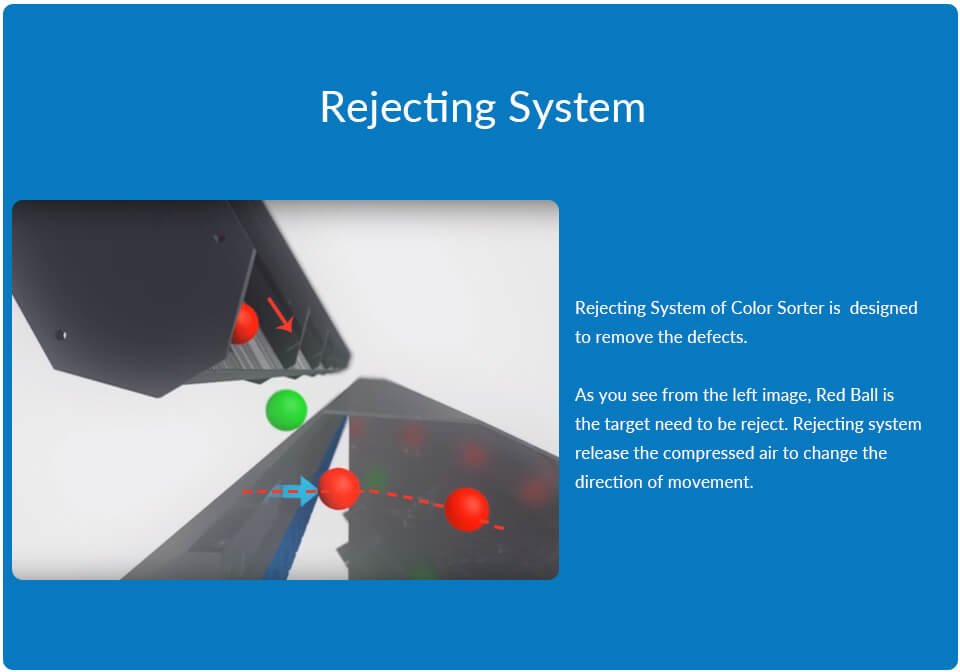

The parts of this system are hopper, air compressors, jet valves, and air purification filters. The main purpose of this system is optically separating good and bad material as identified by the optical system.

The sorter machine has an air compressor that continually provides compressed air. This works with a filter in order to improve the sorting accuracy and prolong the machine’s life.

Rice moves through the post-injection nozzle at high speeds. The silo space should hence be taken good care of.

Dampening measures are employed on the hopper to minimize the chances of rice playing in the bin. The sorter’s accuracy is affected by the nozzle spacing and number of nozzles.

Once digit signals are received from the CPU, ejectors respond quickly, releasing the compressed air. The air changes the rejected material movement route to the reject bin.this separates the bad grains from the good.

Graphic: Ejection System

A color sorter’s efficiency is usually at its best when all these parts or systems are working together.

However, you should not buy an entirely new color sorter if one of these parts is not working. You can get spare replacement parts from a manufacturer, distributor, or agent.

How Does Rice Optical Sorting Machine Work

The processing of rice starts at the milling plant. Here, harvested grains go through a production line whereby rice gets boiled, dried, husked, destoned, shelled, and hulled. From this point, rice is taken into a color sorter machine. The mixture of rice moves through an elevator belt into a hopper on top of the sorting machine from where it flows down along chutes in the color sorter.

Graphic: How does a Rice Optical Sorting Machine work?

The flow is streamlined and scanned by the sorter’s SSD sensors. Once the camera detects a color defect, it instructs ejectors that are machine-fitted to open a nozzle connected to valves with compressed air. The air then shoots the defected rice out the types of rice defected include:

-

White Rice

-

Black Rice

-

Red Rice

-

Glutinous rice

-

Raw Rice

-

Steamed rice

-

Boiled & Parboiled Rice

-

Basmati Rice

-

Vietnamese Rice

-

Long-Grain Rice

-

Thai Fragrant Rice

-

Brown Rice

-

Sticky Rice

-

Jasmine Rice