Rice Colour Sorting Machine History

Rice colour sorters have been around for a number of decades, and the technology has improved over the years with the advancement in integrated circuitry, camera optics and faster ejector valves allowing for machines that process grains faster and with higher capacities on smaller footprints.

Rice Colour Sorting Machine Working principle

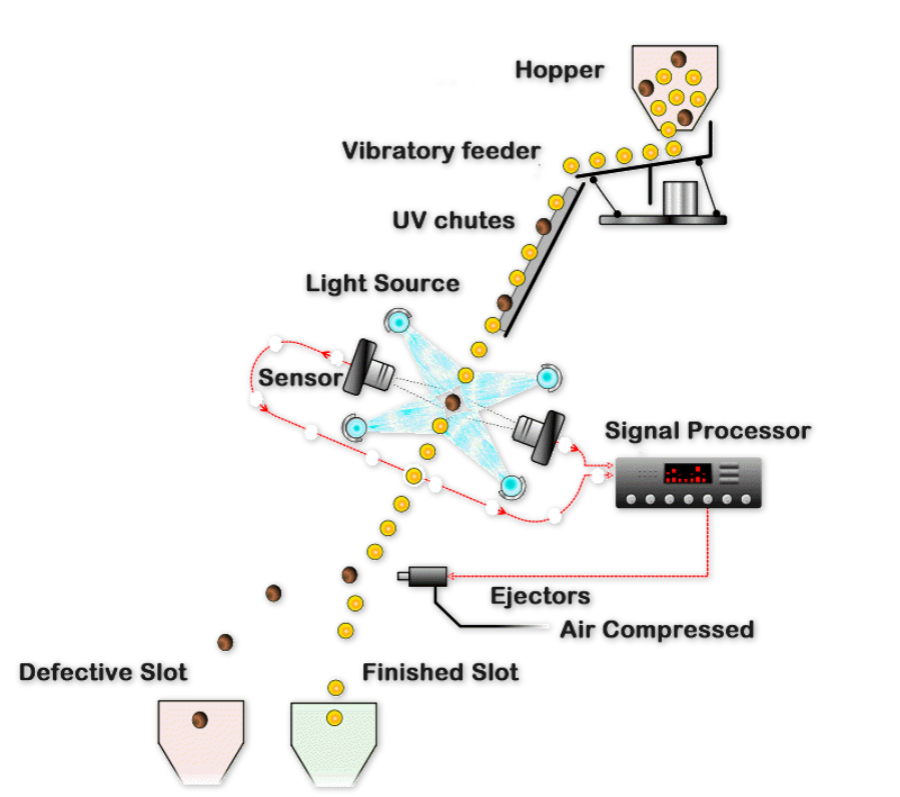

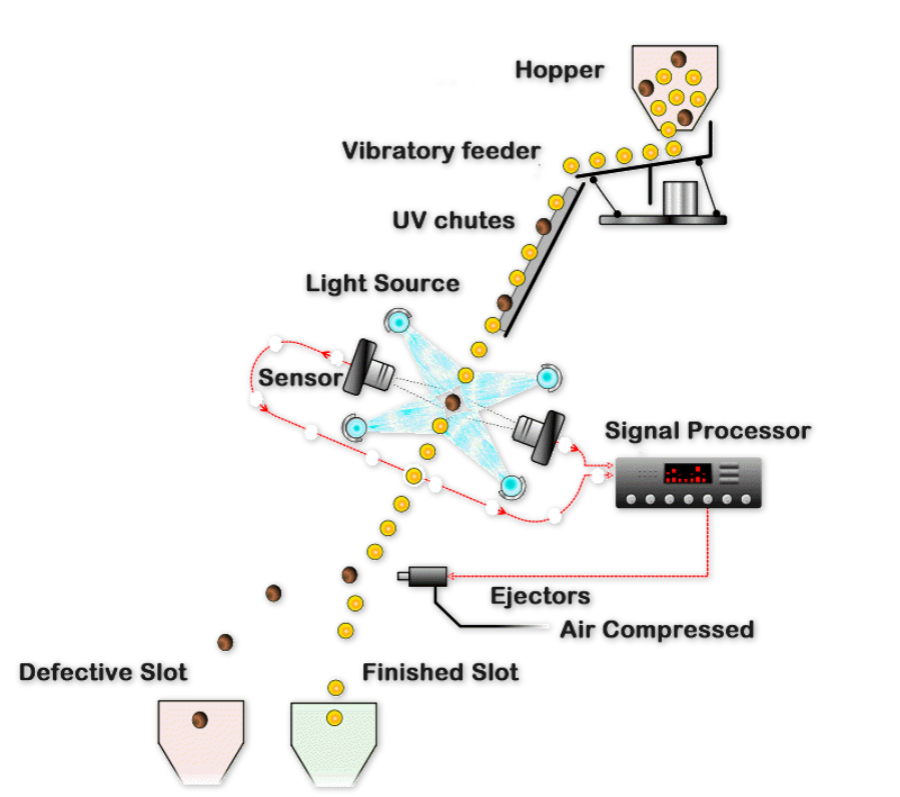

Rice processing begins in a milling plant, where the harvested grains run through a production line where the paddy is boiled, dried, de-stoned, husked, hulled and shelled into rice. It then is taken to the color sorter machine. At this point, the rice mixture will travel by elevator belt into a hopper on top of the machine, from which it will flow down along chutes in the colour sorter, streamlining their flow to so that they may be scanned by CCD sensors. The moment the camera detects any color defects, the camera instructs ejectors fitted in the machine to open the nozzle. The nozzle is connected to valves containing compressed air. This air is then used to shoot out the color defected material from the input rice. The types of defects in rice include black tipped, chalky, yellow, mouse droppings, immature grain, etc.

Working Environment

The working environment: normal temperature, normal pressure, aeration-drying, dust-free place. Working temperature: 20 - 45 degrees °C.

Air system: air compressor, air tank, air dryer connect color sorter solenoid valve. Usually working pressure at least is 0.2 MPa.

Common Voltage: air compressor 380 V, 50 Hz. Color Sorter: 220 V, 50 Hz.

METKEY Rice Colour Sorting Machine Technical Parameter

|

Model

|

SIZE(MM)

|

POWER(KW)

|

Output (T/H)

(take ≤2% polished round-grained rice as an example)

|

Sorting accuracy

(%)

|

Micro yellow recognition

accuracy(%)

|

Chalky recognition

accuracy(%)

|

Ratio of color

separation mass(%)

|

WEIGHT(KG)

|

|

MRCS-126S

|

1244*1504*2090

|

1.5

|

2.0-6.0

|

≥99.99

|

98

|

98

|

>80:1

|

614

|

|

MRCS-189S

|

1558*1504*2090

|

2.2

|

4.0-9.0

|

≥99.99

|

98

|

98

|

>80:1

|

789

|

|

MRCS-252S

|

1872*1504*2090

|

2.9

|

5.0-12.0

|

≥99.99

|

98

|

98

|

>80:1

|

834

|

|

MRCS-315S

|

2186*1504*2090

|

3.6

|

6.0-15.0

|

≥99.99

|

98

|

98

|

>80:1

|

1052

|

|

MRCS-378S

|

2500*1504*2090

|

4.3

|

7.0-18.0

|

≥99.99

|

98

|

98

|

>80:1

|

1265

|

|

MRCS-441S

|

2814*1504*2090

|

4.9

|

9.0-21.0

|

≥99.99

|

98

|

98

|

>80:1

|

1457

|

|

MRCS-504S

|

3128*1504*2090

|

5.6

|

10.0-24.0

|

≥99.99

|

98

|

98

|

>80:1

|

1637

|

|

MRCS-630S

|

3756*1504*2090

|

7.0

|

11.0-30.0

|

≥99.99

|

98

|

98

|

>80:1

|

2018

|

METKEY Rice Colour Sorting Machine Advantage

Cloud Interconnection System

Thanks to cloud service technical platform, remote control, operation, matainence, software

upgrade can be achieved and it can detect and solve the LED light, electronic,mechanical and

adjustment problems.It also can provide real-time online tracking service for the machine operation monitoring,data acquisition and online instruction.

One Key Intelligent Operation System

The users can set the area of the material color, shape, size and defect by themselves and confirm the rejected material,so the machine can automatic set the sorting solution of the material according to the independent calculating, intelligent recognition and intelligent sorting principles with one key intelligent control technology.

Intelligent Visual Image Capture System

It can realize the visual dynamic image capture system by adopting the high resolution full color CCD sensor and beg eye low distortion lens.

Intelligent LED Light Control System

It can adjust the brightness of the LED automatically according to the material sorting requirements and environment changing due to advanced digital stepless automatic LED light adjustment technology. The best sorting performance will be achieved.

Examples of Sorting

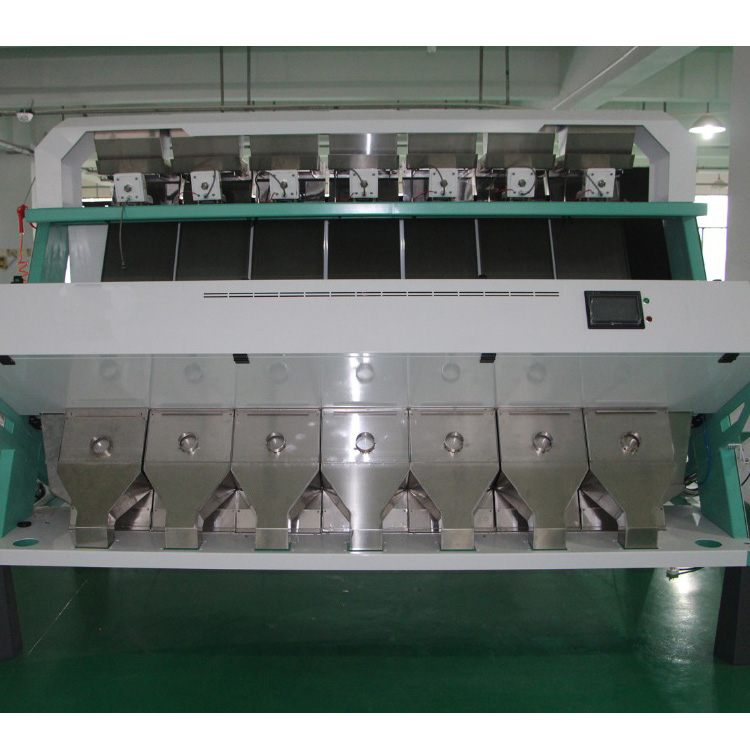

Product Show