Technology Data

|

Model

|

MCCS0001 Corn Color Sorter

|

|

Output(t/h)

|

4-7.5

|

|

Carryover (bad: good)

|

8:1

|

|

Accuracy (%)

|

99.99%

|

|

Voltage (V/Hz)

|

220/50

|

|

Power (Kw)

|

1-2

|

|

Air pressure (Mpa)

|

0.6-0.8

|

|

Consumption (L/min)

|

<2200

|

|

Weight (Kg)

|

500

|

|

Dimensions (mm)

|

1875*1607*1953

|

Corn Color Sorter Machine Features

1. Application of Air-cooled System

2. The application of air-cooled system has solved the problems of high temperature, heavy energy loss and short service life – all of which were caused by longtime utilization of an LED light source, ensuring the durability of an LED light source under a constant temperature.

3. Cloud Object Link System

4. Autonomous cloud control, cloud computing technology, the realization of online operations, online monitoring, online services, free upgrades.

5. Operating System

With intelligent operating platform, the system can be mastered and operated easily, turning the intelligent communication between human and machine into reality and eliminating all your concerns about operating.

6. Color Image Acquisition System

Using high-definition color CCD camera image acquisition system, to achieve material (RGB) red, green and blue three color information acquiring, depth recognition tiny fine color sorter can choose other impurities.

7.Image Processing System

Applying the international advanced 2048 full color scanning technology, DSP+FPGA processing technology, as well as complex algorithm of multiple modes combined with color and space, this system can provide the function of color&shape-based sorting depending on the difference of materials, and allow you to set multiple modes freely and select any material from tens of thousands of ones at your option.

8. Solenoid Valves

The only independently developed dedicated solenoid valves with independent intellectual property rights for color sorters in the industry; special high-strength materials, strong suction, no residual magnetism, linear flow, precise blow, high consistency, significantly lowered optimal carryover; gas consumption for removing 1 ton materials is reduced by 20-30%; the frequency can be up to 1200hz per second, the fastest response time is within 0.5m/s, the service life is 5-10 billion times.

9.Unique Air-suction and Ventilation System

The utilization of the air-suction and ventilation system can help to clear away the floats in the material, ensuring a higher resolution of lens and a more accurate color-based sorting rate.

10.Chute

Based on the varieties of the color-based sorted materials, chutes of appropriate specification can be selected. In addition, the utilization of a four-section leather screen guarantees a more smooth slide of the material and a lower material-taking-out ratio.

11.Ventilation Cooling System

The ventilation cooling system is our pioneering application. Cooled by a ventilation fan, the temperature of sorting cabinet can be reduced efficiently, thus guaranteeing the operating stability of the machine, improving the safety performance of the machine and preventing the machine components from being damaged.

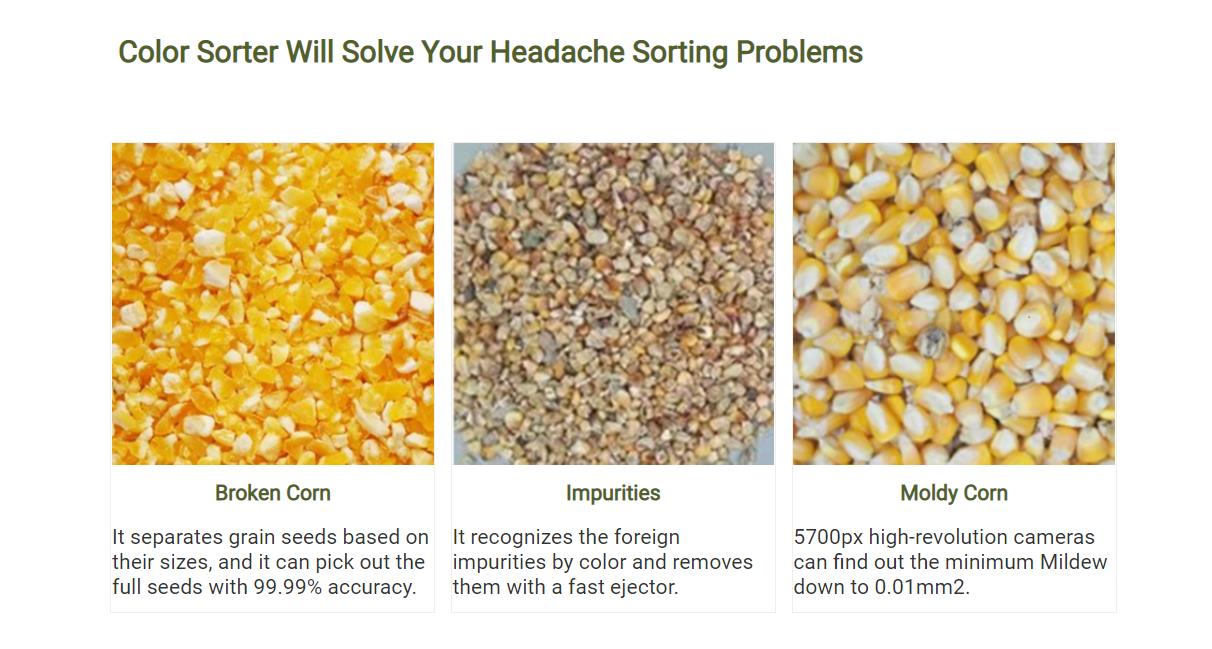

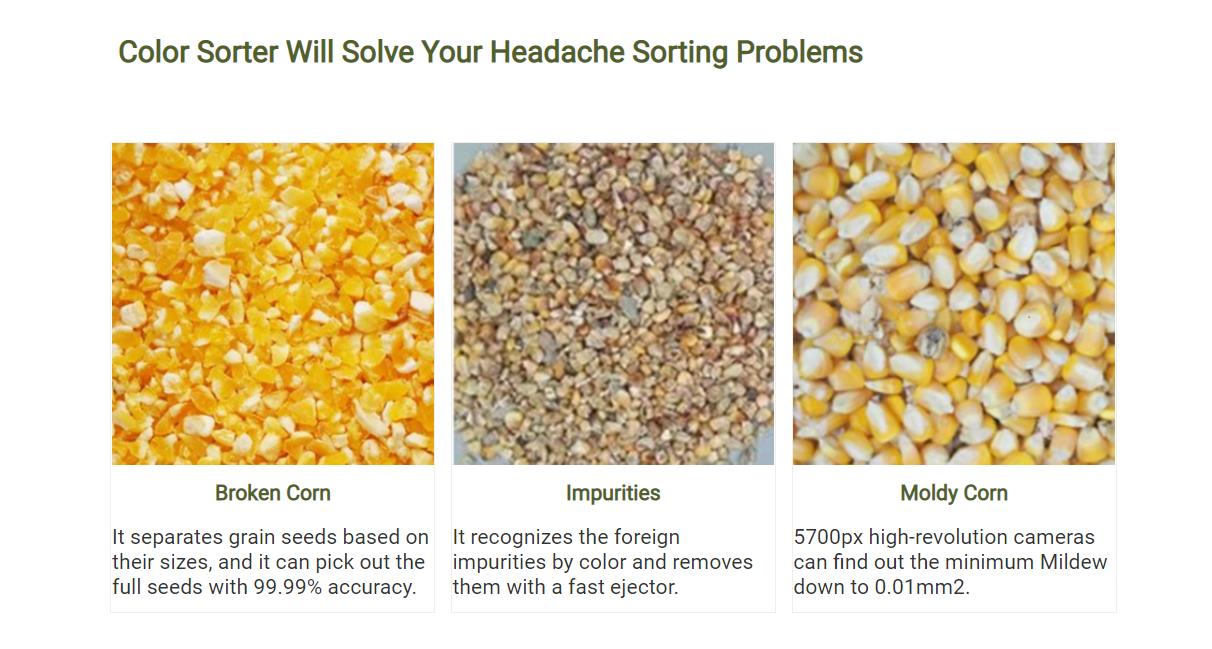

Example of Sorting

Factors influencing the use effect of Corn Color Sorter Machine

Corn color sorting is a process that uses CCD optical imaging technology to screen heterochromatic particles and impurities in corn. After the corn material arrives at the processing location, the output per unit time must be determined. The output is inversely proportional to the accuracy of the color sorter, that is, the greater the output per unit time, the worse the color sorting effect. In order to solve the problem of output and color sorting accuracy, the color sorting channel of the color sorter can be added to solve the problem. Our color sorters are available from single-channel mini color sorters to 12-channel color sorters. Meet the needs of different people.

Removal of the yield factor and the impurity rate is also one of the key factors that affect the color sorting effect. The impurity content is the proportion of heterochromatic particles and impurities in the corn raw grain. The impurity content in the corn material directly affects the color sorting accuracy of the corn color sorter. The higher the impurity rate, the lower the color sorting accuracy, and the worse the effect. Therefore, before starting work, set the relevant parameters such as the working mode of the color sorter according to the impurity content and output of the corn material. After the parameters are set, the selected corn is loaded into the feed hopper of the color sorter through the lifting machine. At this time, the corn is fed from the feed hopper through the vibrating feeder to the chute channel. The rice grains are arranged in the chute channel to adjust the speed to form a single layer of corn flow with uniform speed and slide out of the chute channel and fall into the detection area of the CCD lens. The main control system of the color sorter analyzes and judges the rice flow according to the data collected by the CCD lens, and uses the high-speed jet valve to blow out the rice flow from the defective products in the rice flow and enter the defective product hopper. After color sorting, high-quality corn materials will be sent to the next process for processing, and defective products will be stored separately for processing.