Technical Parameters

|

Model

|

Tea Color Sorter Machine MTCS0004

|

|

Output(kg/h)

|

<800

|

|

Carryover (bad: good)

|

>5:1

|

|

Accuracy (%)

|

99%

|

|

Voltage (V/Hz)

|

380/50

|

|

Power (Kw)

|

6.8 – 8.6

|

|

Air pressure (Mpa)

|

0.6-0.8

|

|

Consumption (L/min)

|

<5400

|

|

Weight (Kg)

|

3286

|

|

Dimensions (mm)

|

2676*2530*3432

|

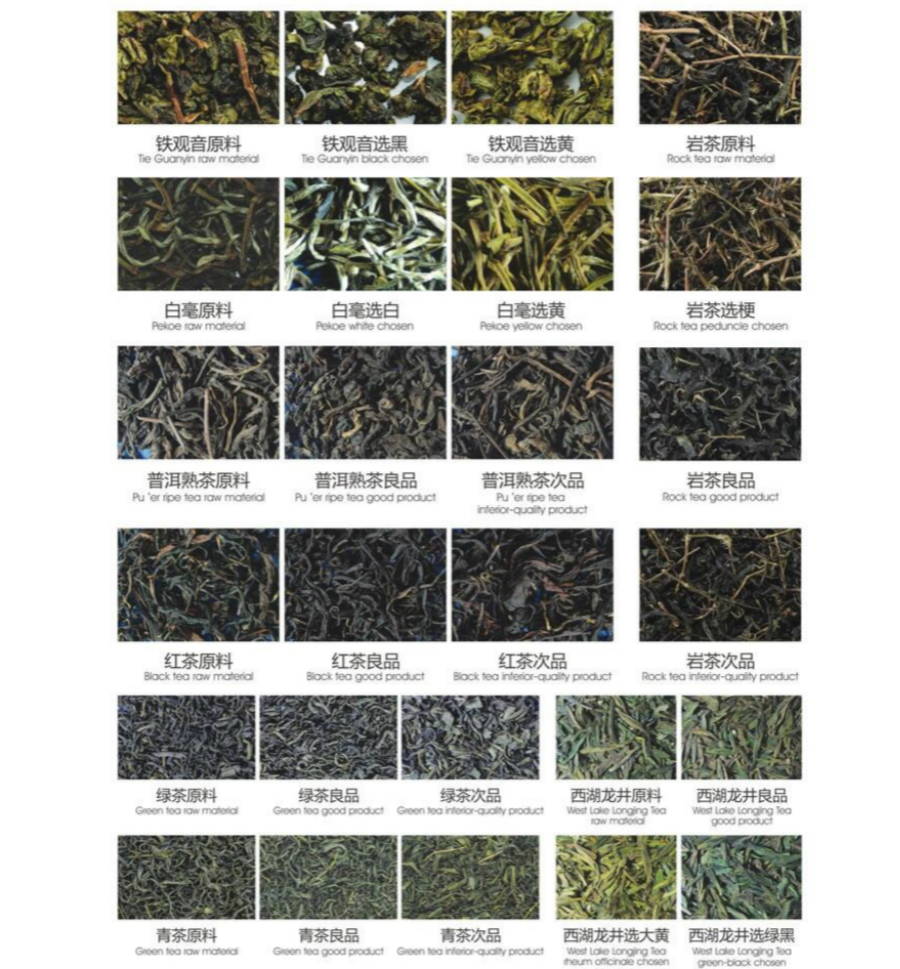

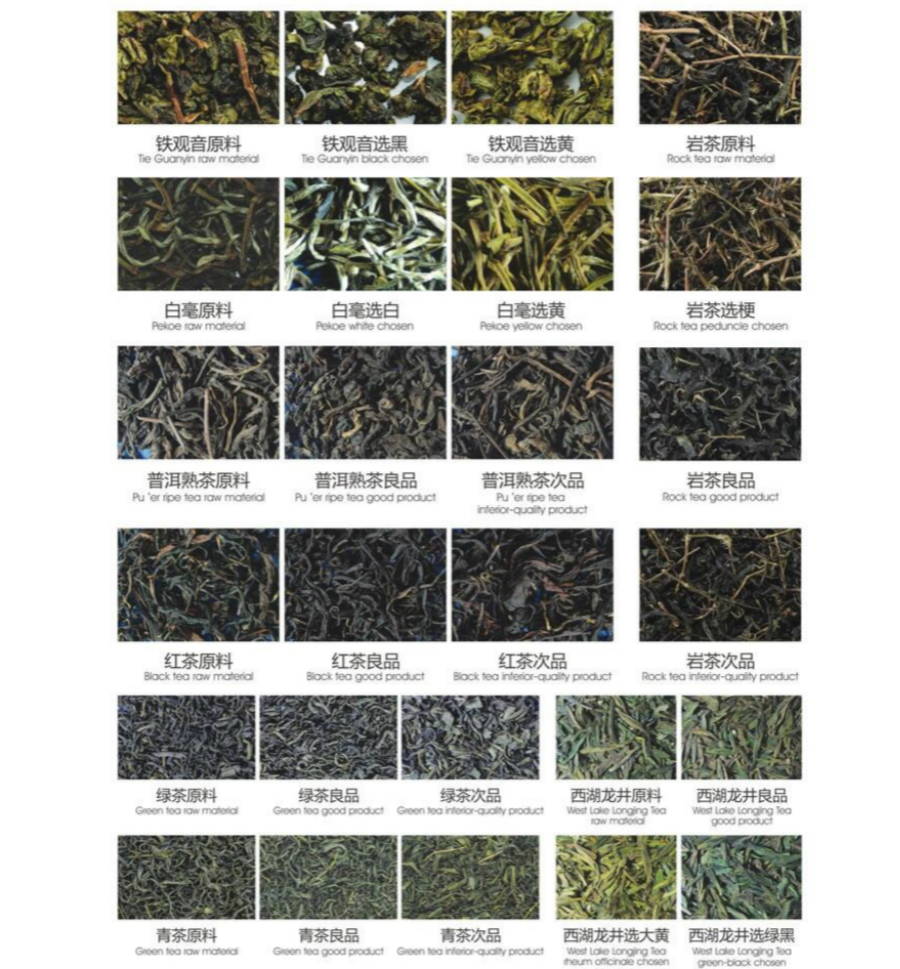

Examples of Sorting

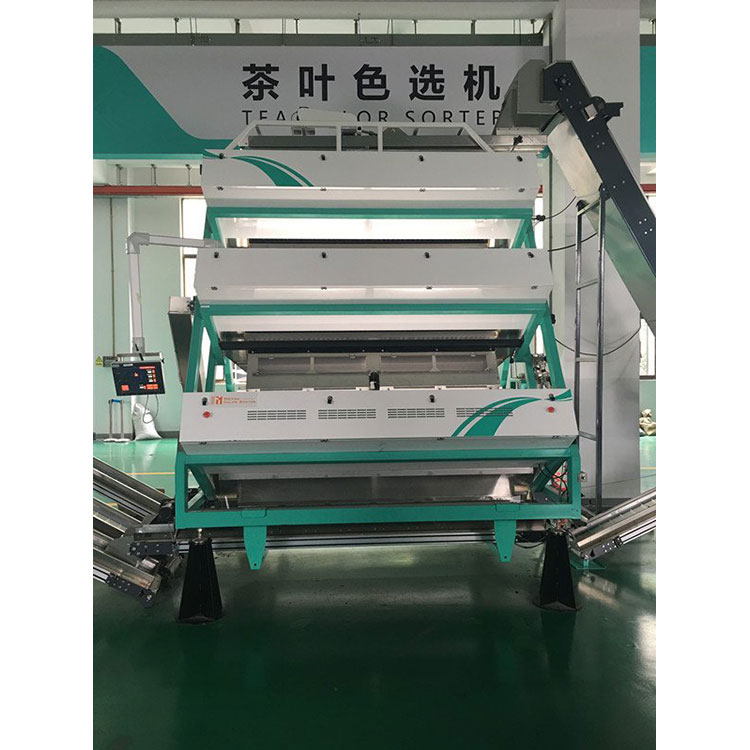

Tea Color Sorter Machine Advantages

1. Design of mechanical-electrical integration:The integration of sorting cabinet and electrical cabinet results in a more stable overall mechanical structure, prolonging the service life of the machine and making the maintenance much easier.

2. The original material-distributing system in the industry:The latest-designed Bridge-type material-distributor is featured with low noise, low jitters amplitude, high vibration frequency, and more even sorting, settling the problems of uneven sorting and underproduction, which are often seen in currently-used material-distributor matched with three-tier tea-sorting machine.

4. Utilization of air cooling system,this system settles the problems of high temperature, heavy energy loss, light source instability, and short service life which are caused by a longtime-working LED light source.. In addition, the system ensures an endurable light source used in a constant temperature.

5. Solution of independent sorting mode,for each tier, a sorting solution of either color-based or shape-based can be set separately, and a combining sorting solution of color&shape-based can also be chosen. You can choose the solution freely.

6. Unique design of broadening sorting chamber,this design can solve the problem of partial tea-sorting caused by swirling air, increase the output and reduce the crashed rate during the course of tea sorting.

7. The original blowing nozzle, together with the valve-driven mode, helps to accelerate the response speed, strike more accurately, reduce the material taking-out ratio, increase the output, as well as decrease gas consumption by 20%.

8. Cloud object link system,autonomous cloud control, cloud computing technology, the realization of online operations, online monitoring, online services, free upgrades.

9. The original design of intelligent LED shadow-less cold light source system, having a light emitting rate is high, the use of longer and stronger anti disturbance, and easier to identify, judge more easily, don’t more precision characteristics, meet a variety of tea 360 degree of shape and color selection requirements.

10. The world’s top custom industrial CCD sensor and color selection of the lens, high-definition imaging technology, taking pictures of the selected tea images, can be selected in the different color and shape of the tea to define the color. The minimum resolution in the range of o.o8MM2, the tiny spots, black spots signal amplification processing needle.

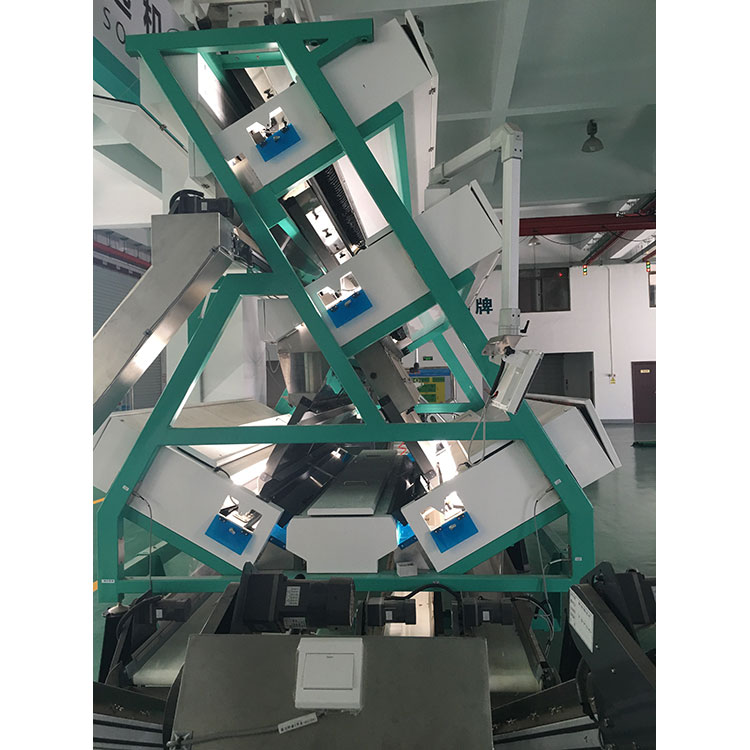

11. V integrated design,The three layer, four layer V structure, integration, convenient installation and daily maintenance to meet the needs of different customers.

12. V structure design,Can be used to sort the pre sorting box of waste, can be back to the rear of the sorting box, a sorting to complete the finished product and the net, the color selection of higher accuracy, lower crushing rate, more convenient operation.

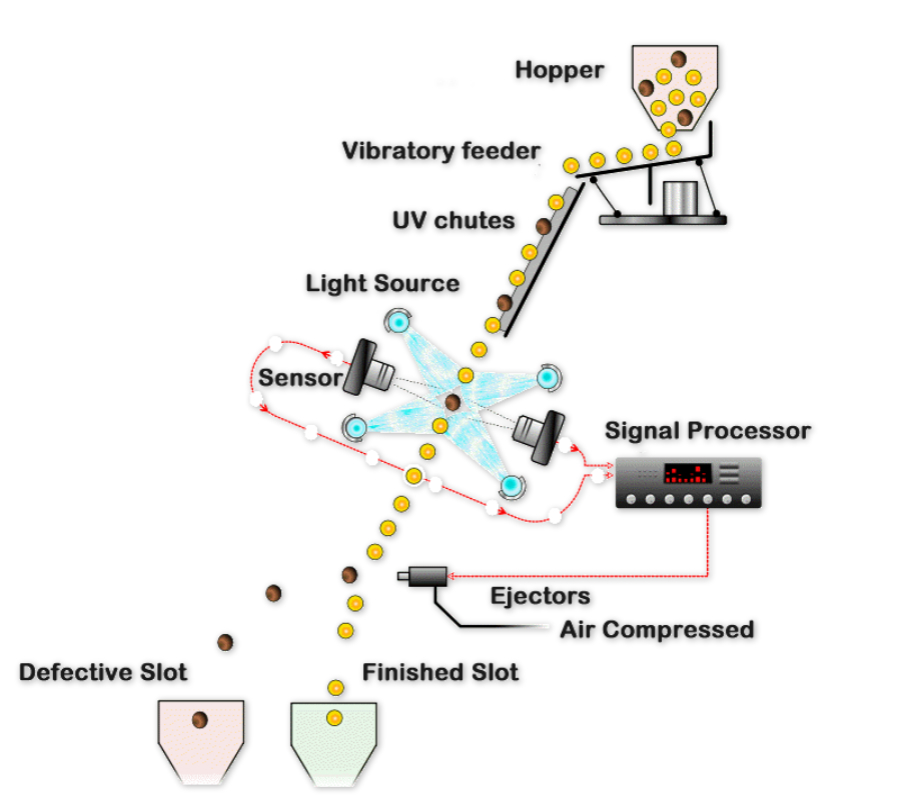

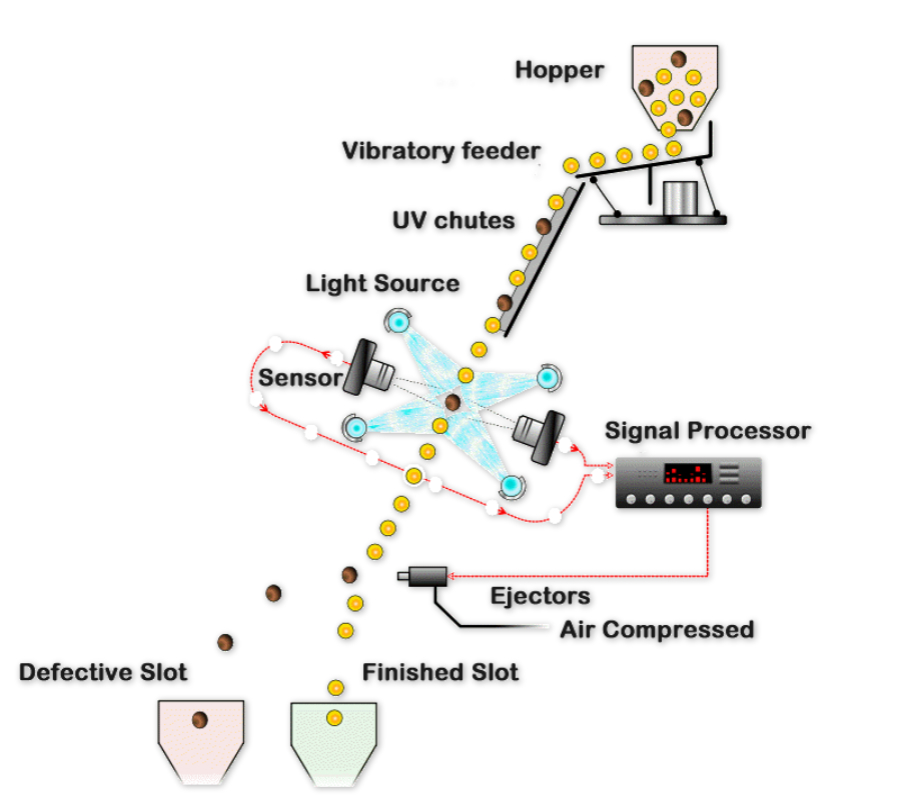

Tea Color Sorter Machine Working principle

Before working, according to the proportion and type of material of bad tea, set the color selection mode and machine production; tea materials and then will be sorting through a special tea color sorter to hoist conveying swing into the hopper, the hopper to swing into vibrating feeder, vibrating feeder vibrating chute feed through to the upper chute (i.e. color channel) material, the material in the chute chute in tea by aligning track arrangement, the formation of the separation zone detection rate more uniform flow of tea material down to the color selected photoelectric sensor detection area or CCD lens scanning, discrimination, discrimination, tea material flow in poor poor products by high speed jet meters remove tea material jet nozzle. Through the tea material sorting into the lower upper hopper into the lower chute chute again using color photoelectric sensor detection area or CCD lens scanning, detection and separation zone discrimination, discrimination, culling, sorting by good and defective two positions to the next step.

Commissioning and Installation:

1. On Site Installation and Training Service by our professional engineer ;

2. Study and Learn the Machine Operation in Our Factory.

3. Responsive in 24 hours: Telephone, Email, Video or On Site Solutions by our Technical Experts.

Packaging & Shipping

Machines to be carefully packaged to endure transportation under harsh conditions. Handling instructions are designed to protect the machine in the critical moments during transportation, unloading and installation.

Delivery Time: 10-15 Days after order confirmed.

Payment Terms: TT, Letter of Credit.

After Sales Services:

• With presence in a variety of countries, Wuxi Tuanjiuhe Technology Co., Ltd. is strongly committed to being close to the customer.

• Through cooperation with loyal and carefully evaluated and trained local employees and partners, Wuxi Tuanjiuhe Technology Co., Ltd. managed to provide fast, competent and rooted services in the context of customers.

• Application center in Wuxi production base offer demo machines for tests and comparison.

• A strong central technical team in Wuxi is supporting local channels with training, advice and technical support.

• Under normal working circumstances, Wuxi Tuanjiuhe Technology Co., Ltd. enjoy 1 year of full warranty and a lifelong warranty on the machine structure upon the date of purchase.

• Service line is available for emergency support.

• Wuxi Tuanjiuhe Technology Co., Ltd. will be serviced and supported wherever customers are located.

• Through the global Wuxi Tuanjiuhe Technology Co., Ltd. network and from Wuxi Tuanjiuhe Technology Co., Ltd. technical experts, training on Wuxi Tuanjiuhe Technology Co., Ltd. is available worldwide.