Product Description

Four Layer CCD Tea Color Sorter refers to the high-tech opto-mechanical equipment that uses the high-definition CCD optical sensor to select the tea using the color difference between the tea stem, the yellow piece and the genuine one in the tea.

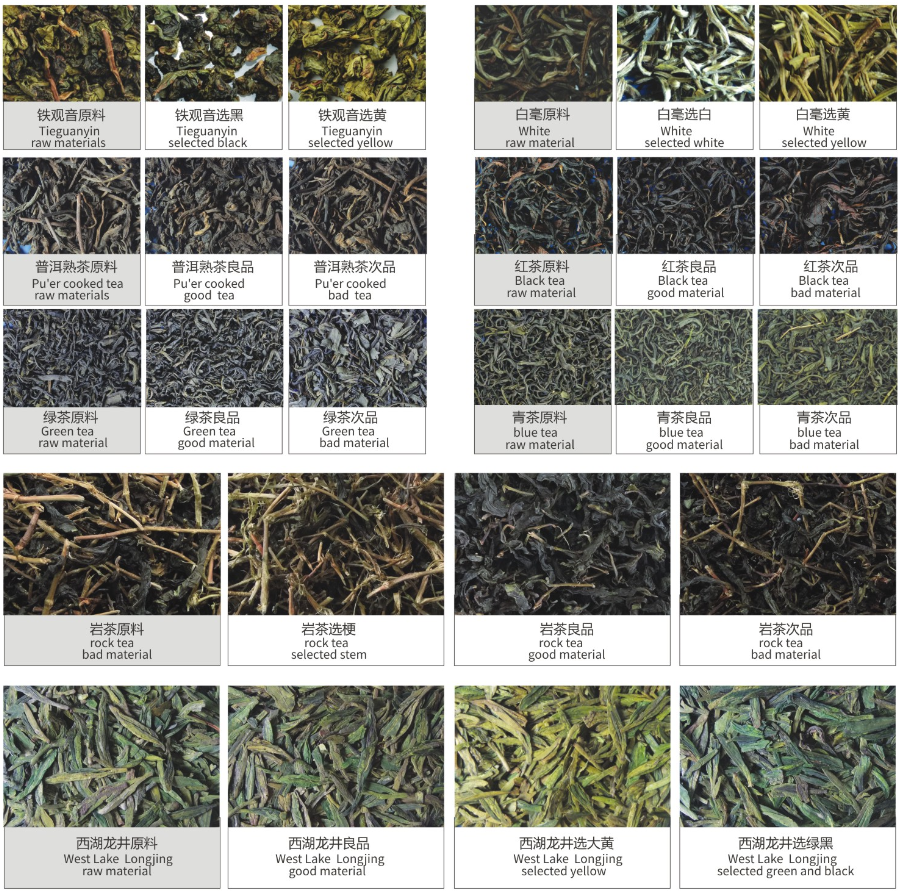

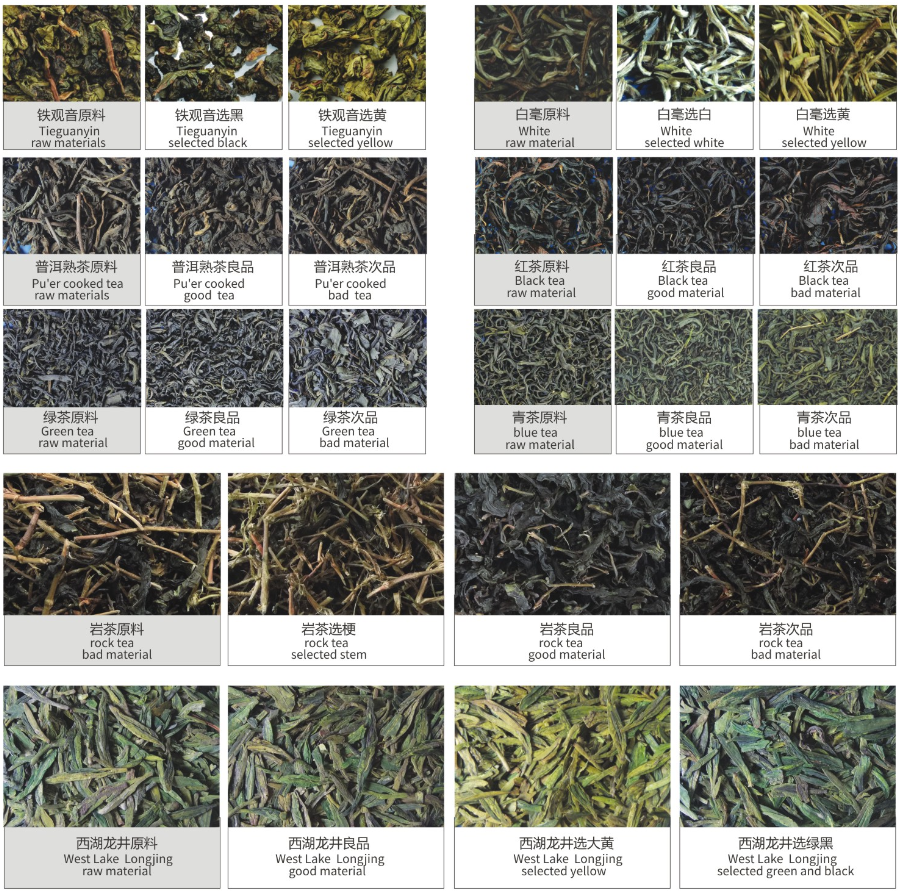

In the tea industry, more than 80% of domestically produced tea, including Tieguanyin, can be color-selected using Four Layer CCD Tea Color Sorter.

Compared with manual selection: labor saving, time saving, high efficiency and low processing cost. Improve the quality, economic and social benefits of selected products.

Four Layer CCD Tea Color Sorter Technical Parameters

|

Product Name

|

T4VS6 Four Layer CCD Tea Color Sorter

|

|

Yield (kg / h)

|

<800

|

|

Carryover (bad: good)

|

>5:1

|

|

Choose the net rate (%)

|

> 99%

|

|

Power supply voltage (v / Hz)

|

380V50Hz

|

|

Power (Kw)

|

6.8-8.6

|

|

Air pressure (Mpa)

|

0.6-0.8

|

|

Air consumption (L / min)

|

<5400

|

|

Weight (Kg)

|

2400

|

|

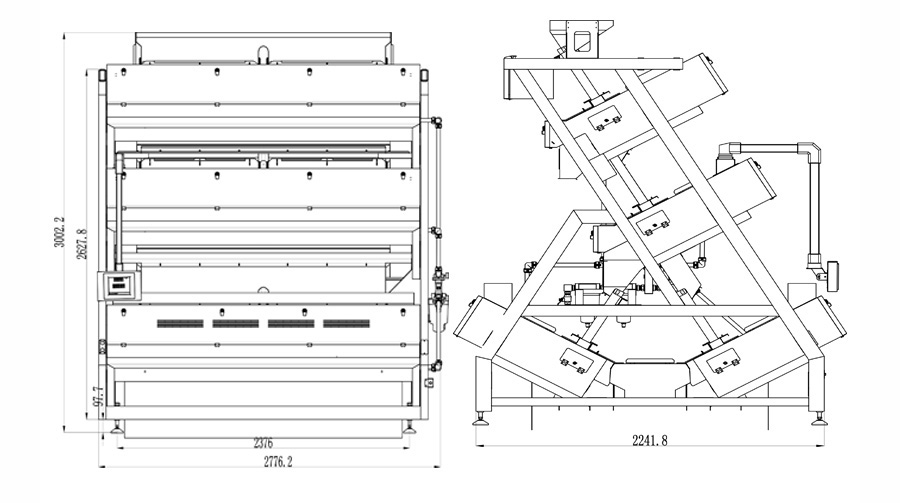

Dimensions (mm)

|

2676*2530*3432

|

Note: The above parameters are hetero-election of 3% green tea, for example, the yield will vary depending on the raw material impurity rate.

Examples of Sorting

Four Layer CCD Tea Color Sorter Function & Features

1.Design of mechanical-electrical integration: The integration of sorting cabinet and electrical cabinet results in a more stable overall mechanical structure, prolonging the service life of the machine and making the maintenance much easier.

2. The original material-distributing system in the industry: The latest-designed Bridge-type material-distributor is featured with low noise, low jitter amplitude, high vibration frequency, and more even sorting, settling the problems of uneven sorting and underproduction, which are often seen in currently-used material-distributor matched with three-tier tea-sorting machine.

3. Utilization of air cooling system, this system settles the problems of high temperature, heavy energy loss, light source instability, and short service life which are caused by a longtime-working LED light source.. In addition, the system ensures an endurable light source used in a constant temperature.

4. Solution of independent sorting mode, for each tier, a sorting solution of either color-based or shape-based can be set separately, and a combining sorting solution of color&shape-based can also be chosen. You can choose the solution freely.

5. Unique design of broadening sorting chamber, this design can solve the problem of partial tea-sorting caused by swirling air, increase the output and reduce the crashed rate during the course of tea sorting.

6. The original blowing nozzle, together with the valve-driven mode, helps to accelerate the response speed, strike more accurately, reduce the material taking-out ratio, increase the output, as well as decrease gas consumption by 20%.

7. Cloud object link system, autonomous cloud control, cloud computing technology, the realization of online operations, online monitoring, online services, free upgrades.

8. The original design of intelligent LED shadowless cold light source system, having a light emitting rate is high, the use of longer and stronger anti disturbance, and easier to identify, judge more easily, don't more precision characteristics, meet a variety of tea 360 degree of shape and color selection requirements.

9. The world's top custom industrial CCD sensor and color selection of the lens, high-definition imaging technology, taking pictures of the selected tea images, can be selected in the different color and shape of the tea to define the color. The minimum resolution in the range of o.o8MM2, the tiny spots, black spots signal amplification processing needle.

10. V integrated design,The three layer, four layer V structure, integration, convenient installation and daily maintenance to meet the needs of different customers.

11. V structure design,Can be used to sort the pre sorting box of waste, can be back to the rear of the sorting box, a sorting to complete the finished product and the net, the color selection of higher accuracy, lower crushing rate, more convenient operation.

Mounting Dimensions