Product Description

Peanut Intelligent Color Sorter is used for separating the bad peanuts from the raw material through the color difference between the rejection and finished products.

METKEY Peanut Intelligent Color Sorter adopts domestic advanced anodizing process chute, international famous brand Pro-Face high sensitivity touch screen, Italy Matrix high frequency solenoid valve, Japan Nikon high definition aperture / focal length independent adjustable lens, automatic tracking and corrected algorithm operating system. It has the advantages consists of large output, high color selection precision, long life, long maintenance period, stable performance and high cost performance. It is the best choice compared with similar color sorting machines.

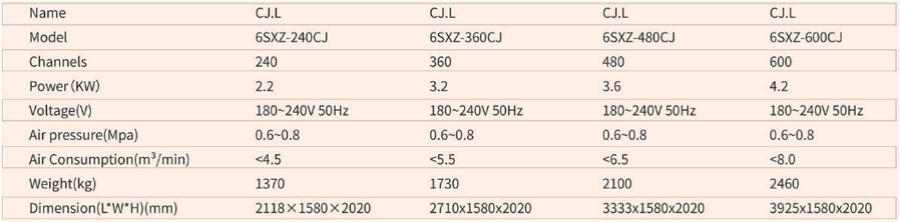

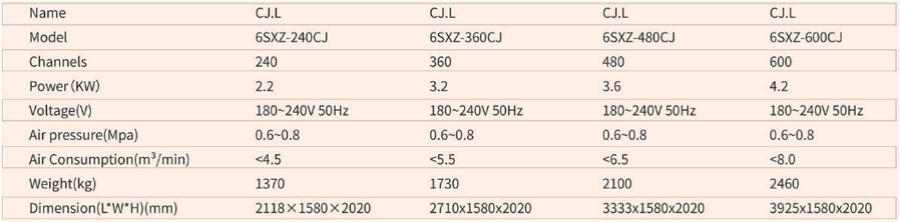

Peanut Intelligent Color Sorter Technical Parameters

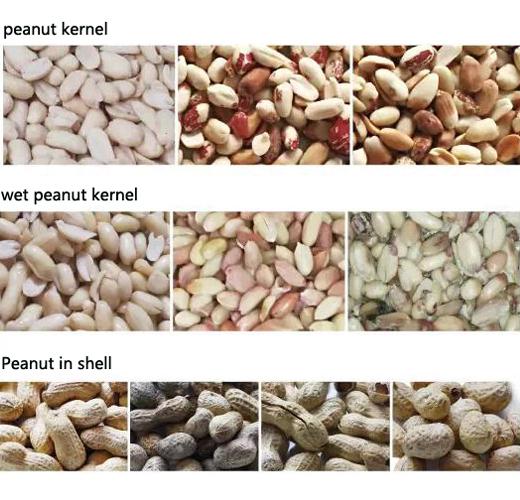

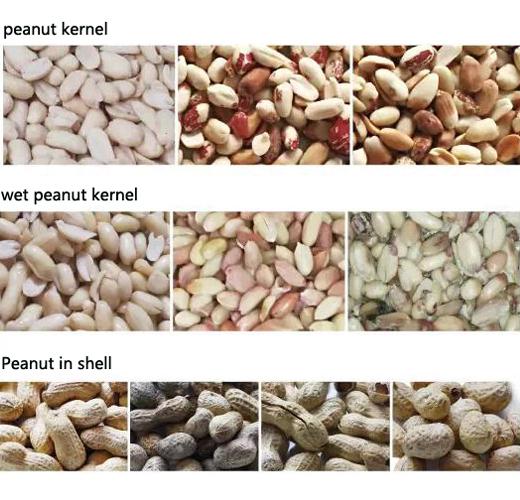

Examples of Sorting

Sorting is done by hand as well as using CCD optical sorter. The blanched peanuts are transferred to the CCD color sorter machines automatically. Electric eye sorter separate infected and good quality peanuts based on their color and size. As a result, fungus infected peanuts are rejected by the machine. Peanut which are accepted as a good quality by the sorter machine will be sorted again by hand. The sorted peanut are then bagged in bags and sample will be taken from each bag for Aflatoxin analysis.

Peanut Intelligent Color Sorter Function & Features

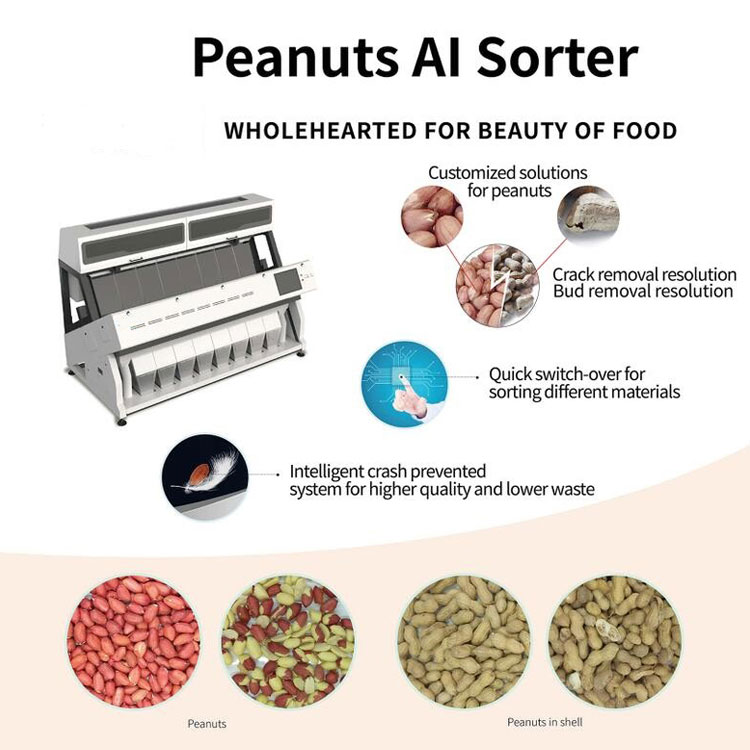

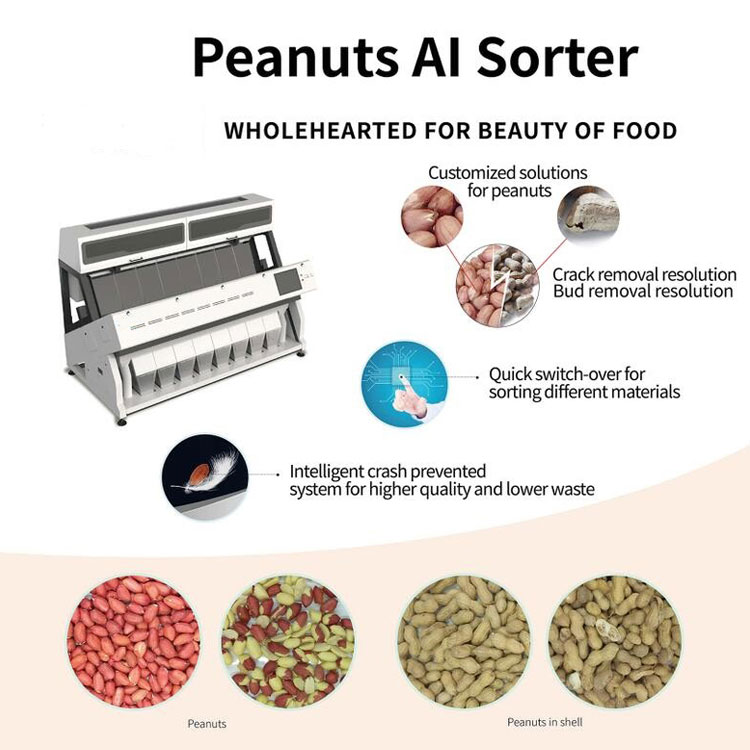

1.Customized solutions for peanuts

2.Crack removal resolution;bud removal resolution

3.Quick switch-over for sorting different materials

4.Intelligent crash prevented system for higher quality and lower waste.

Ten years ago, peanut sorting mostly relied on manual work and easily interfered by subjective factors, which caused high labor cost and low efficiency. METKEY applied color sorting technology to peanuts processing. With the development of intelligent identification technology, peanut color sorter has become the key of peanuts quality control and widely used in this industry. Today, combined with AI, what kind of value it will create for you continuously?

Intelligence makes a difference

▶Compound Eye illumination system, Two cameras 3D REBUILDING

METKEY color sorter "see it more clearly"

▶Targeted Sorting Technology

METKEY color sorter "aim at it more accurately"

▶Maglev ejector, Intelligent Crash Prevented System

METKEY color sorter "remove it more completely"

Intelligent interaction makes operation easy

▶Extremely simplified interaction:Quick switch-over of sorting solutions,easy operation even for children.

▶Remote Commissioning:Online instruction solves problems quickly

▶Automatic backup:Scheduled backup of key data to the cloud for calling excellent sorting solutions anytime

▶Auto-check & Auto-tuning:Regular auto-check and auto-tuning for sorter key data of signal, lighting, alarms and dust to ensure excellent performance of sorters.

Ultra-high precision for super effect

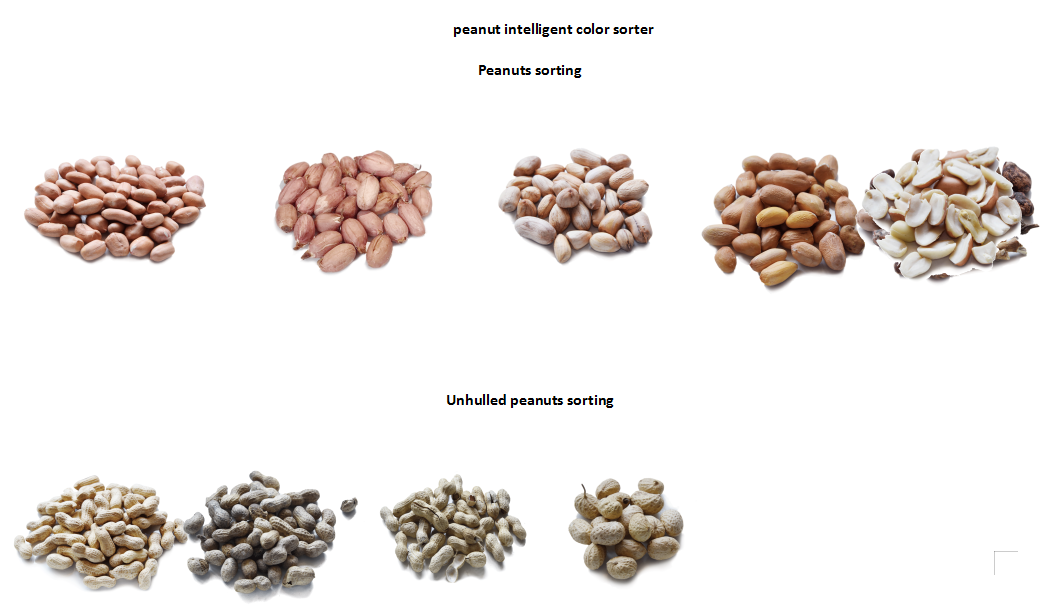

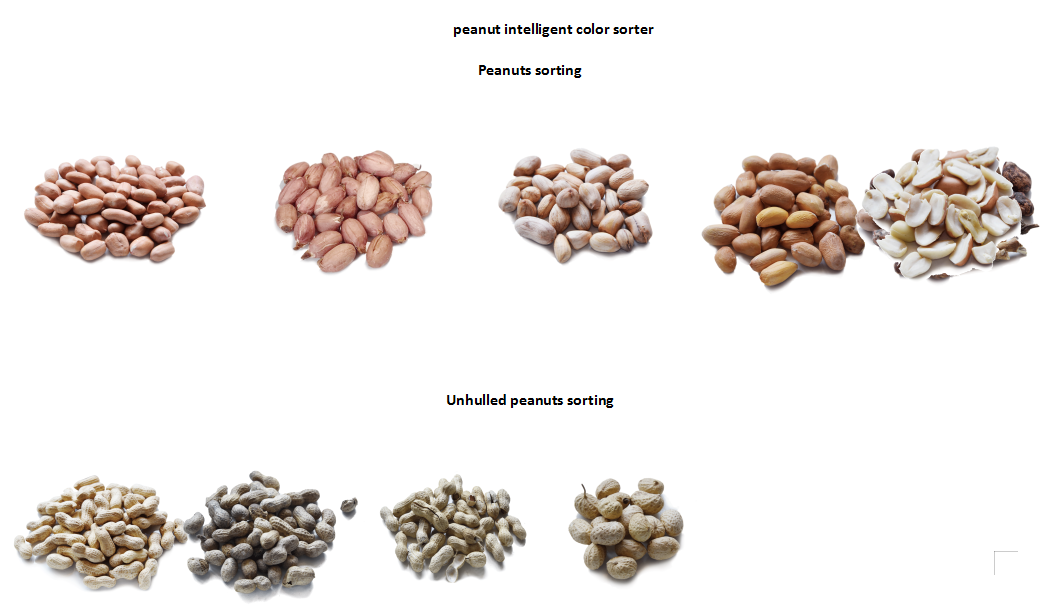

▶The removal rate of unhulled peanuts with crack, hole and broken ones is 30% higher than conventional sorters.

▶The removal rate of peanuts with short bud is 50% higher than conventional sorters.

▶The removal rate of frozen and different color peanuts is 15% higher than conventional sorters.

Notes:

Based on the standardized and modular mechanical structure design, under the intelligent factory standard for streamlined manufacturing, METKEY peanut intelligent color sorter can realize the true stability and reliability.