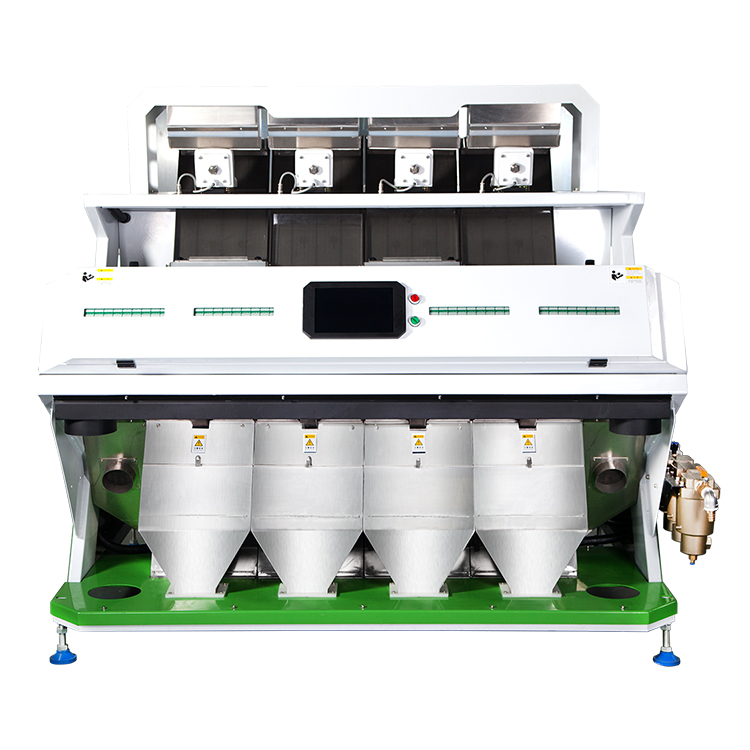

Arabica and Robusta Coffee Been Sorting Machine Introduction

Most fine coffee goes through a battery of machines that sort the coffee by density of bean and by bean size, all the while removing sticks, rocks, nails, and miscellaneous debris that may have become mixed with the coffee during drying. First machines blow the beans into the air; those that fall into bins closest to the air source are heaviest and biggest; the lightest (and likely defective) beans plus chaff are blown in the farthest bin. Other machines shake the beans through a series of sieves, sorting them by size. Finally, a machine called a gravity separator shakes the sized beans on a tilted table, so that the heaviest, densest and best vibrate to one side of the pulsating table, and the lightest to the other.

The final step in the cleaning and sorting procedure is called coffee bean optical sorting machine, or separating defective beans from sound beans on the basis of color rather than density or size. Color sorting is the trickiest and perhaps most important of all the steps in sorting and cleaning. With most high-quality coffees color sorting is done in the simplest possible way: by hand. Teams of workers pick discolored and other defective beans from the sound beans. The very best coffees may be hand-cleaned twice (double picked) or even three times (triple picked). Coffee that has been cleaned by hand is usually called European preparation; most specialty coffees have been cleaned and sorted in this way.

Color sorting can also be done by machines. Streams of beans fall rapidly, one at a time, past sensors that are set according to parameters that identify defective beans by value (dark to light) or by color. A tiny, decisive puff of compressed air pops each defective bean out of the stream of sound beans the instant the machine detects an anomaly. However, these machines are currently not used widely in the coffee industry for two reasons. First, the capital investment to install these delicate machines and the technical support to maintain them is daunting. Second, sorting coffee by hand supplies much-needed work for the small rural communities that often cluster around coffee mills. Nevertheless, computerized color sorters are essential to coffee industries in regions with relatively high standards of living and high wage demands.

METKEY Arabica and Robusta Coffee Been Sorting Machine comprehensive product portfolio has been carefully developed to offer processors the best solutions for conventional and challenging sorting applications. The MCCS range has four technology variants, each designed in different levels for defect detection.

Subtle colour sorting

multiple visible wavelengths (for example: red, green and blue) .This can detect the subtlest colour variations of coffee beans

Superior colour sorting

two visible wavelengths (in this example: red and green).

This can detect not only light and dark defects but also other colour variations.

Simultaneous light and dark sorting

uses two visible wavelengths independently (in this example: red and green).

This is for detecting both light and dark defects simultaneously.

Independent light or dark sorting

The standard RGB color sorter uses one visible wavelength (in this example: either red or green).This is best suited for mainstream colour sorting applications which include removing light or dark defects.

CCD color sorters is ideal for sorting Arabica coffee beans, removing a variety of defects to increase product quality and safety.By incorporating the latest technological advances, defects such as sticks, stones, odd colors beans and other foreign seeds can be removed effectively and efficiently.

For primary defects, we have a very high efficiency in eliminating serious defects or completely stained grains (black and red)

METKEY Arabica and Robusta Coffee Been Sorting Machine Technical Parameters

|

Model

|

MCCS-68

|

MCCS-136

|

MCCS-272

|

MCCS-408

|

MCCS-612

|

MCCS-680

|

|

Output(t/h)

|

0.6-1

|

1.2-2

|

2.4-5

|

4-7

|

6-10

|

8-16

|

|

Carry over Rate(Bad:Good)

|

>12.5:1

|

>12.5:1

|

>12.5:1

|

>12.5:1

|

>12.5:1

|

>12.5:1

|

|

Sorting Accuracy

|

≥99.99%

|

≥99.99%

|

≥99.99%

|

≥99.99%

|

≥99.99%

|

≥99.99%

|

|

Voltage(V/Hz)

|

220V 50HZ

|

220V 50HZ

|

220V 50HZ

|

220V 50HZ

|

220V 50HZ

|

220V 50HZ

|

|

Power Supply(Kw)

|

1.0-1.3

|

1.4-1.8

|

2.5-2.9

|

4.8-5.2

|

6.6-7.2

|

8.5-10.5

|

|

Pressure(Mpa)

|

0.4-0.6

|

0.5-0.7

|

0.6-0.8

|

0.6-0.8

|

0.6-0.8

|

0.6-0.8

|

|

Air Consumption(L/min)

|

<1000

|

<1800

|

<3200

|

<4800

|

<5600

|

<6100

|

|

Weight

|

260kg

|

440kg

|

820kg

|

1180kg

|

1620

|

2200

|

|

Dimension

|

950*1510

*1428mm

|

1290*1510*1770mm

|

2010*1530*2100mm

|

2680*1530*2100mm

|

3710*1530*2100mm

|

4200*1530*2250mm

|

Remark:We have many models from 1 chute to 16 chutes for option to meet any different production capacity.The exact production capacity may change due to different impurity level.

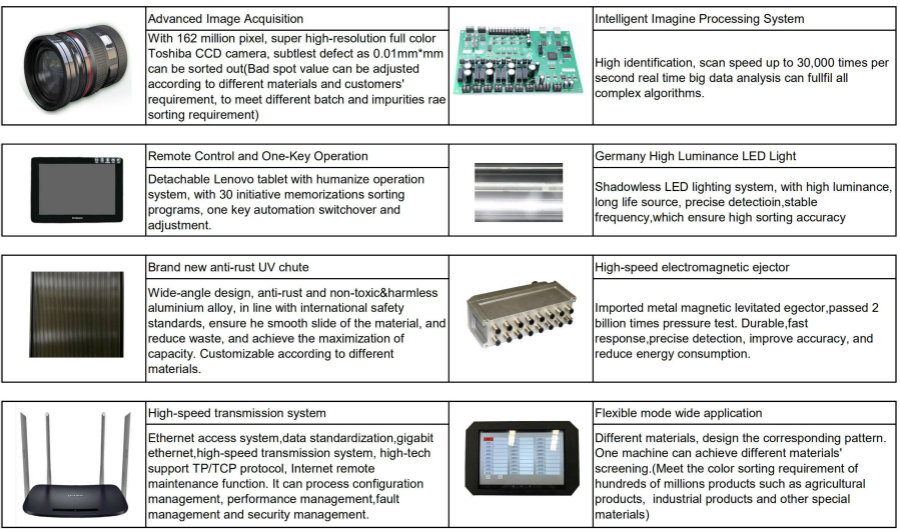

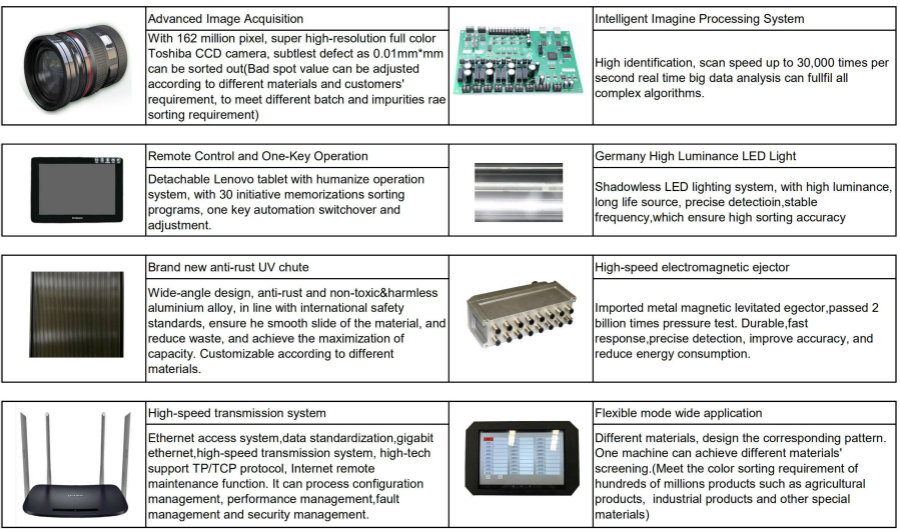

METKEY Arabica and Robusta Coffee Been Sorting Machine Advantages

1.Linear array CCD adopt full-color sorting technique, high resolution for full color, High speed sorting recognition is more exquisite.

2.Blend in Shape recognition technique,more precise to make a grade to the rice and grain.

3.Visible full color light spectral distribution, free to adjust the spectral region.

4. It can be suitable to sort a variety of grains, industrial products, other particles and sheet material through choose different sloping chute.

5.High resolution imaging technology,take the pictures to collect the images of sorted products,it can be defined sorting for thousands of materials and 100,000 colors, truly achieve wide use color sorting.

6.Each group can independently and simultaneously process multi-tasking and multi-mode color sorting,multi, anti-election and multi-color simultaneously.

7.High Brightness,long-life LED light can satisfy to different products and color,and needn't to change LED light.

8.Powerful software platform, easy to lear and know, simple to operate.