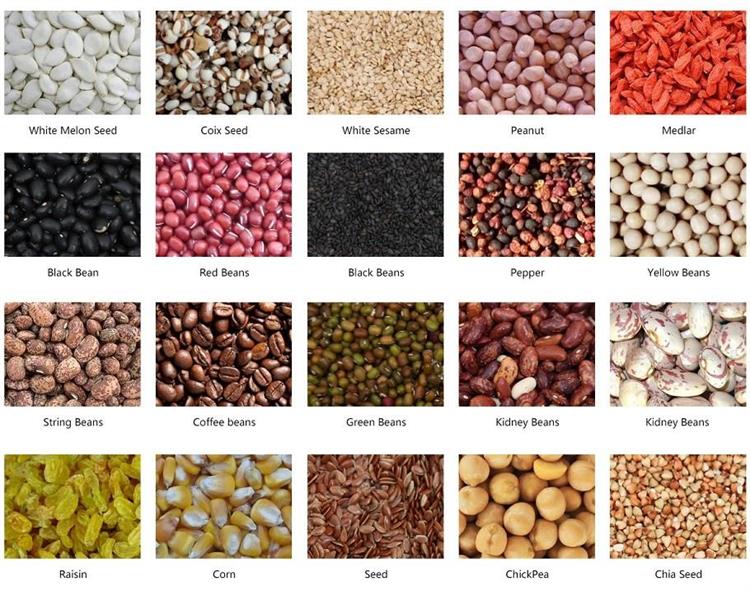

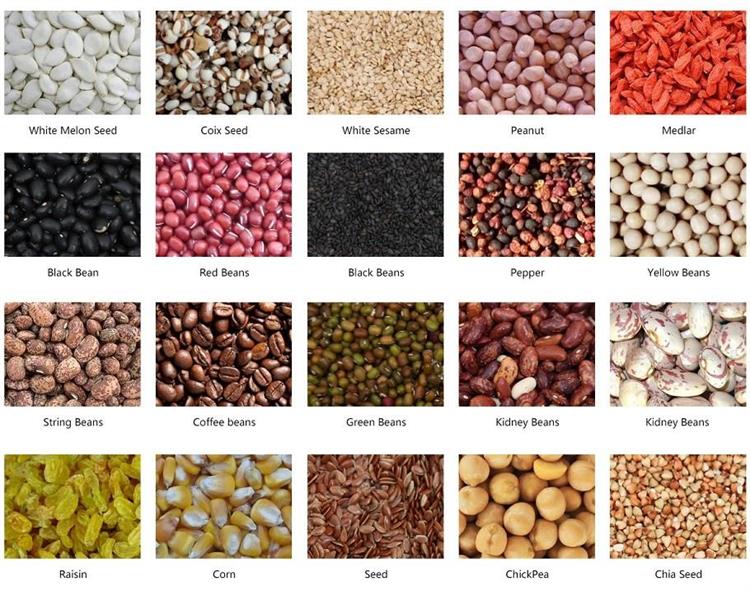

The Pulses Color Sorter machine is ideal for Pulses processors who sort different varieties of dry beans:black beans,borlotti beans,flageolet beans,kidney beans,mung beans,soybeans, lentil,chickpea ,dry bean,dry pea and so on.The sorting range is suitable for processors who demand the highest in pulses quality,offering precision sorting to maximize yields and increase profits.

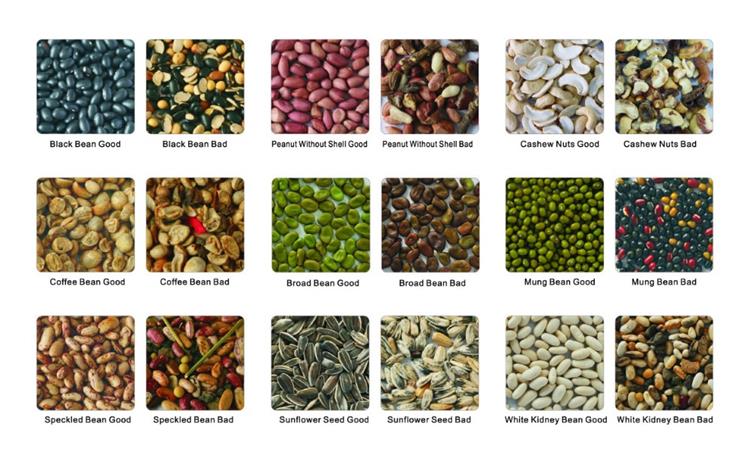

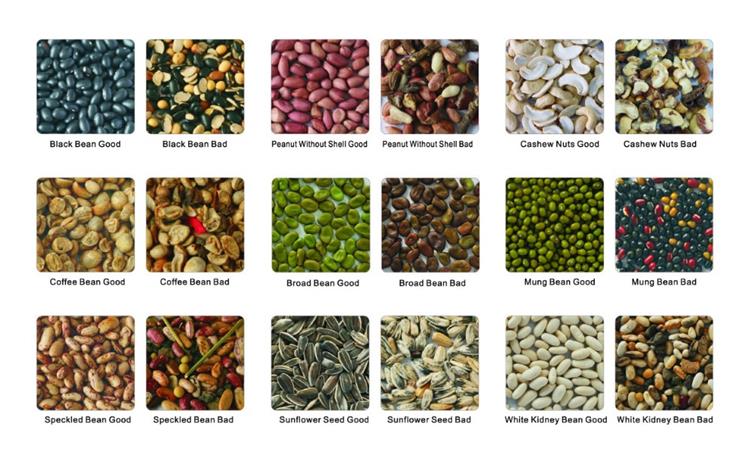

Kidney Bean Color Sorters are equipped with the latest in technological advances and intelligent features.It effectively detects such as discolored beans,broken,Split beans,stones and sticks and remove them,leaving processors with a clean,safe and quality of beans.

Kidney Bean Color Sorter Technical Parameter

|

Model

|

MBCS0001

|

MBCS0002

|

MBCS0005

|

MBCS0008

|

|

Executing unit

|

64

|

128

|

320

|

512

|

|

Throughput(T/H)

|

0.5-3

|

1-4

|

5-10

|

11-20

|

|

Voltage(V)

|

110-250V/50-60HZ

|

|

Power(KW)

|

1

|

1.4

|

2.6

|

4

|

|

Weight(KG)

|

480

|

660

|

1200

|

1580

|

|

Dimension(MM)

|

960*1630*2050

|

1340*1630*2050

|

2225*1630*2050

|

3068*1630*2050

|

|

Sorting accuracy (%)

|

≥99.99

|

|

Rejection rate

|

≥20:1

|

|

Air consumption (L/Min)

|

400-800

|

600-1000

|

1300-2200

|

2200-4000

|

|

Notes

|

Subject to different impurities of raw materials, parameters listed in table will change to some extent

|

Sorting Material with METKEY Kidney Bean Color Sorter

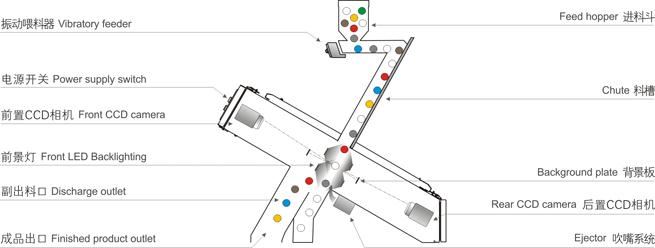

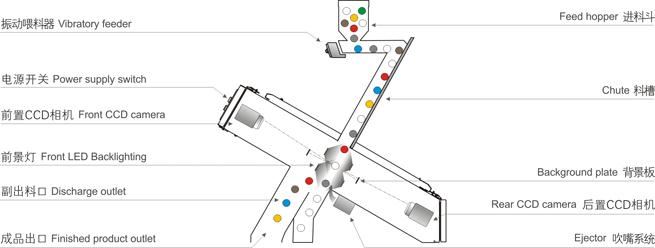

Kidney Beans Color Sorter Working principle

Advantage of Kidney Bean Color Sorter

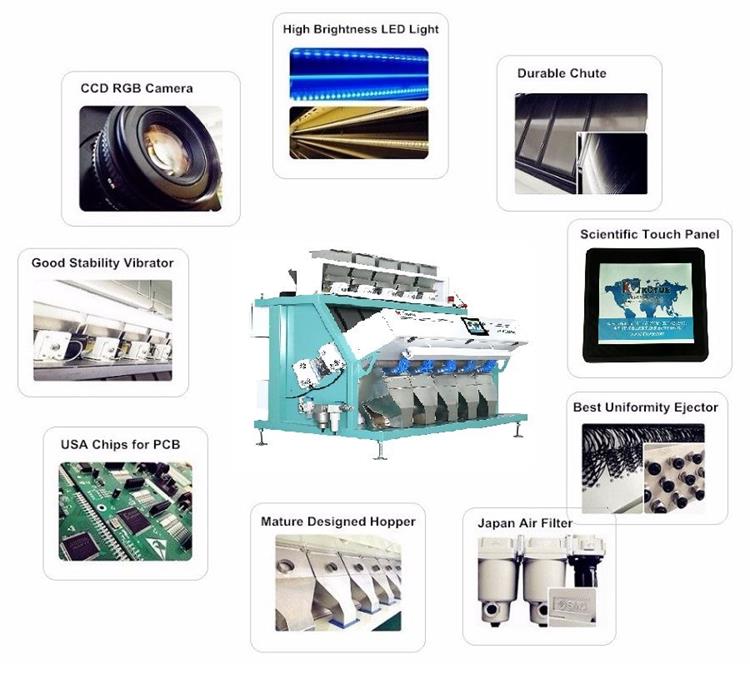

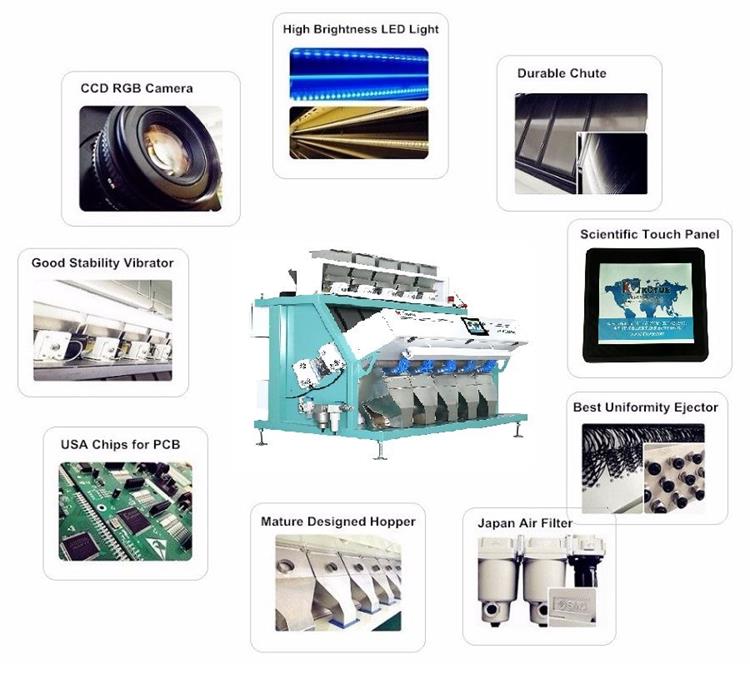

1,Near human eye vision color sorting technology, using 16 million colors, brings the best sorting performances

2,Full-color cameras optical system, with dimensional control of the defects, allows 0.1mm optical resolution

3,image acquisition allows the easy and accurate setting of the defects to remove. Software adjustment is completely automatic thanks to HSV technology

4,Shape-sizing integrated into the system

5,Most concentrated rejects, thanks to customized hi-tech ejectors

6,Highest production capacities, automatically regulated by a feeder control device

7,Possibility to have simultaneous product resort, even with reverse sorting and third sorting.

8,Possibility to add sloping chutes for sorter upgrading or production increase

9,Possibility to install additional cameras operating in NIR and InGaAs even after machine installation at working premises

10,Led lighting system which is digital control

11,Automatic cleaning system, with adjustable frequency and duration

12,Tilting optical boxes, to allow an easy internal access for maintenance operations

13,Airtight optical boxes with controlled temperature

14,Designed mechanics grants the highest hygiene and prevents product outflow or accumulation

15,Provision with de-dusting suction systems

16,14-inches display with full-color and multilingual touch-screen

17,Flexible and user-friendly

18,Reduced electric and compressed air consumption.

19,CE certification

20,Use best quality components to ensure excellent quality.

21,from one chute to sixteen chutes to meet any different production capacity requirement