Product Description

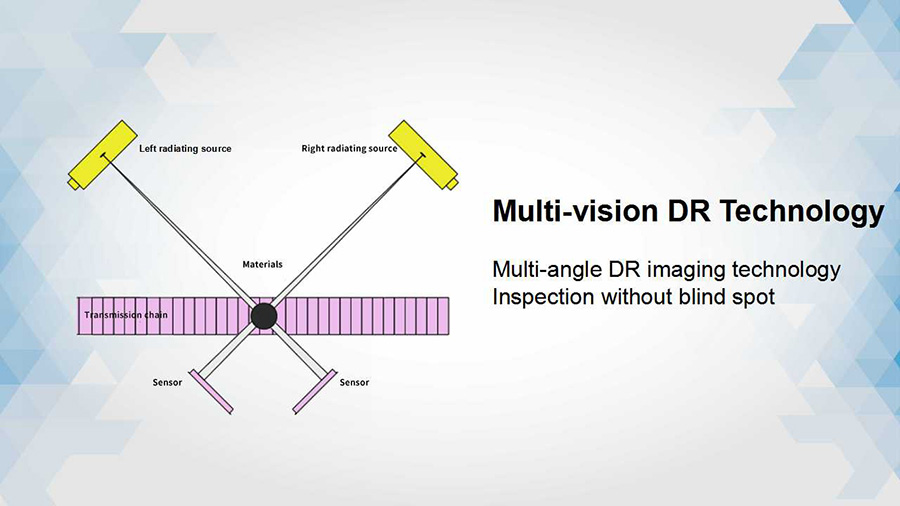

X-Ray Sorting Machine makes use of the object’s intensity difference in absorbing X-ray to discriminate the foreign matter with larger density. Bulk cargo integral X-ray inspection system can satisfy unique handling and detection requirements of mobile product in bulk, and help food raw materials and food producers & suppliers to obey strict HACCP Protocol and food safety regulations.

It is applicable to dead angle-free detection recognition and all-round & accurate elimination of physical foreign matter in bulk cargo including food raw materials (such as peanut, etc.), dehydrated vegetables, raisins, nuts, candies, and so on. For example, it can effectively defect kinds of metal and nonmetal foreign matters (such as stone, glass, dense plastic, ceramic, hard bone, rubber, etc.) in bulk cargo (like peanut) and pebble inlaid in peanut.

X-Ray Sorting Machine advantage

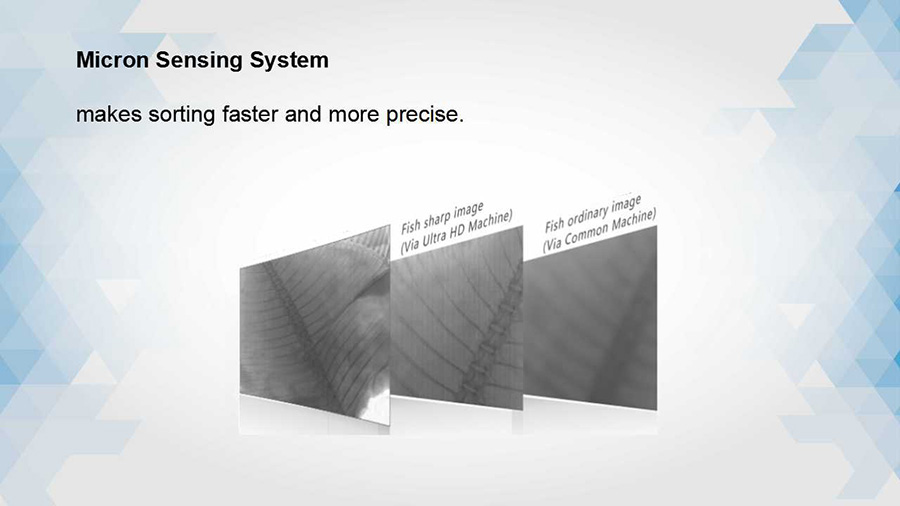

1、Micrometer Sensing System

Accurate recognition with no blind corner, over 50% boost in detection speed, unparalleled output.

2、Smart Detecting Brain

One button to push, detection process visible, easy and reliable.

3、 Sky Eye Platform

Distance management via mobile and PC, unattended control realized.

4、Self-optimization Platform

One push to update the system, best operating experience ever.

5、Black Shield Platform

Comprehensive database installed, automatic data recovery ensured, manufacturing tools secured.

6、Self-adaptive Service

Stable in different settings, flexible to customized needs.

Technical Parameters

|

Model

|

SS-X8084SSF-S X-Ray Sorting Machine

|

|

Dimension(L*W*H)

|

3200*1500*2100mm

|

|

Net Weight(kg)

|

720kg

|

|

Sensitivity

|

Stainless steel ball>φ0.3mm;Stainless steel wire>φ0.2*2mm

|

|

X-ray Output

|

350W,80KV/8mA

|

|

Human-machine Interface

|

17-inch touch screen

|

|

Speed of Belt

|

10-100m/min(Adjustable)

|

|

Width of Belt

|

470mm

|

|

Radiation Leakage

|

≤1μSv/h

|

|

Protection Grade

|

Transmission part rated to IP66,others rated to IP54

|

|

Service Environment

|

Temperature:0-40℃;Relative Humidity:30%-85% without dew

|

|

Air Pressure(MPa)

|

0.6-0.8MPa

|

|

Air Consumption

|

≤0.3m³/min

|

|

Voltage(V)

|

Sing-phase AC 220V±10%,50/60Hz,2Kw

|

|

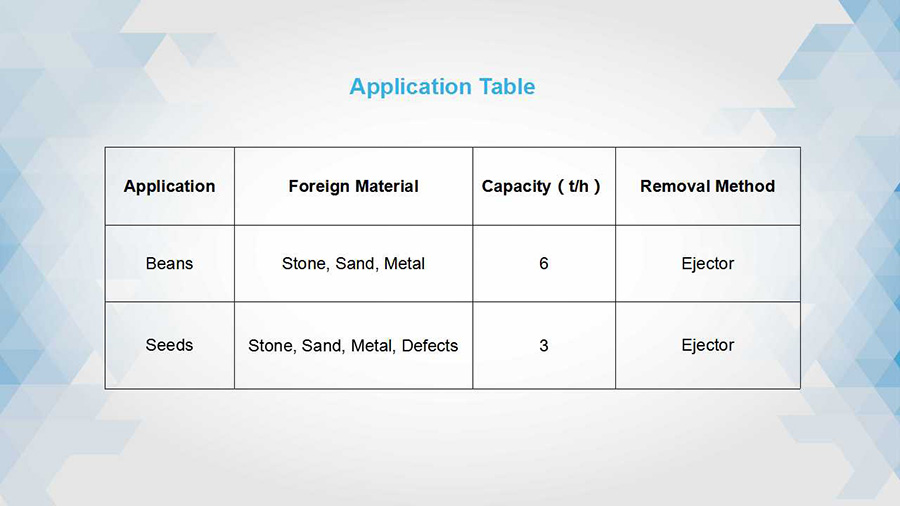

Capacities

|

Sunflower Seeds:3t/h;Beans:6t/h

|

Note: The specific index varies on the basis of different grains with different rate of foreign materials.

X-Ray Sorting Machine Applications

1.Beans,seeds and other agricultural products

2.Inspection of foreign materials:remove metal,stones,glass,sands and bones precisely.

3.Defects inspection:detect and remove defects including the injured kemel and products with seeds left.

Function & Features

Why should customers trust METKRY X-Ray Sorting Machine

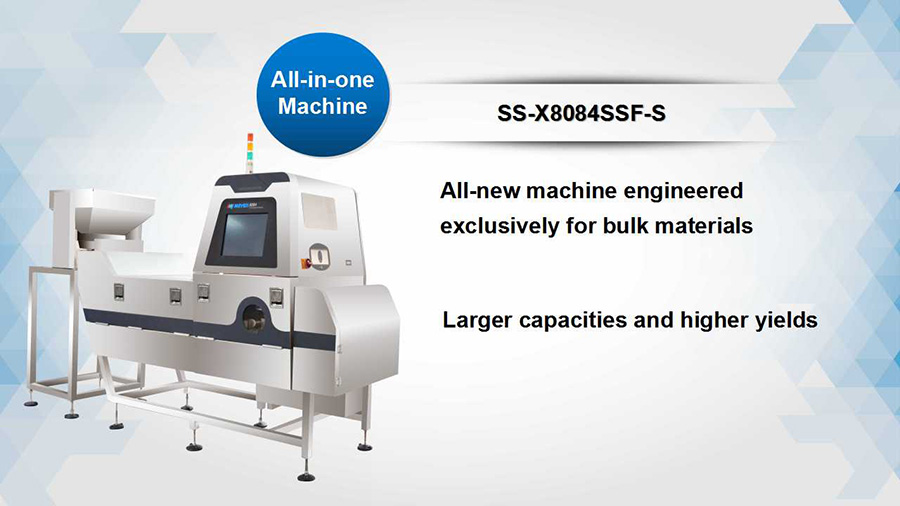

1.Larger

* Larger capacities and higher yields.

* 3 tons of oil seeds per hour; 6 tons of beans per hour.

2.Fast

* The custom hardware system with inspection speed approaching 100 meters per minute and response time of the ejector reaching 1 millisecond.

3.Easy to use

* Equipped with a new and larger 17inch touch screen user interface, simplifying usability for the operator combined with the automatic trouble diagnosis system.

4.New

* All-new structure design combined with automatic monitor of materials delivers higher precision of removal.