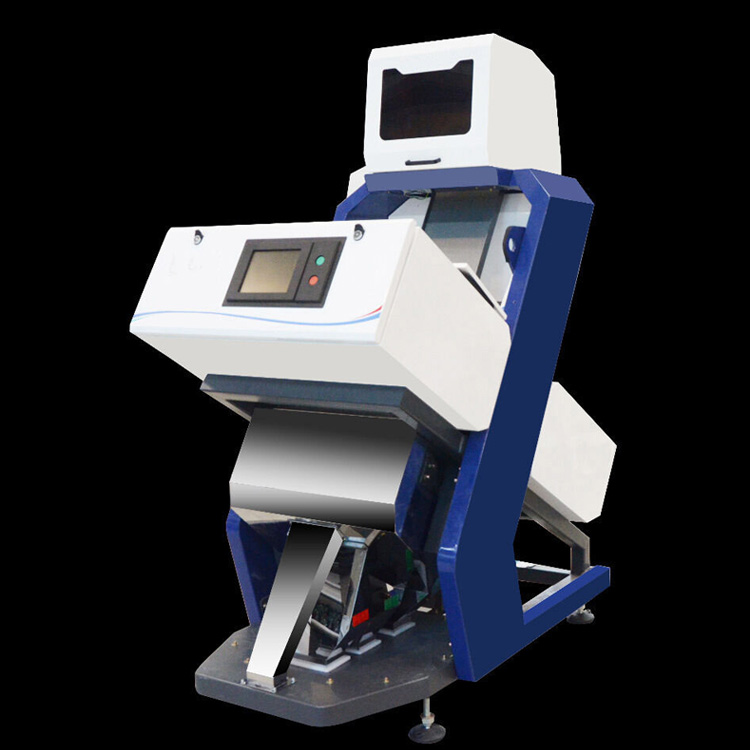

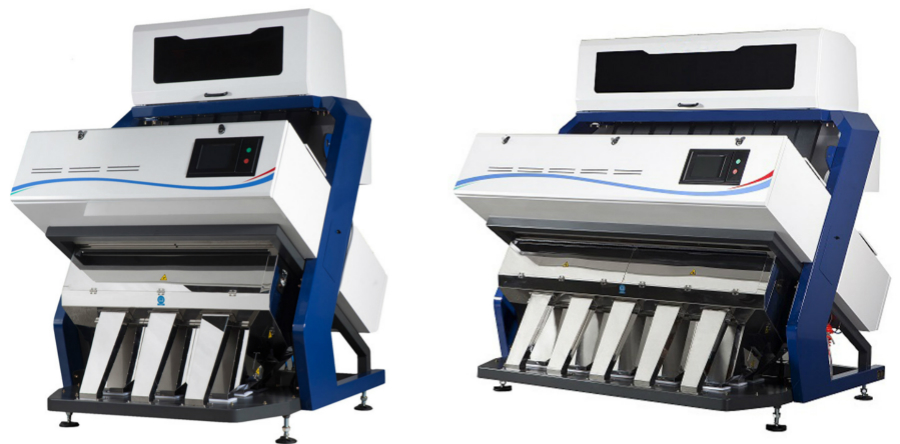

NIR Optical Plastic Sorting Machine Operational Principle

Material goes through hopper into the machine, shaken by the vibration device, the material slides through distributing box, an then pass through detector and background board. Under the light resource, the light sensor receives compound light from the material, and the system sends out signals, driving the movement of the ejection valve, and remove off color material to the eject chamber. Accepted material freely falls down to the finished-product chamber, so that the material is precisely sorted.

Device characteristic

* Efficiently sort needed material from rejected one.

* Separate various colors;

* Strengthened spout and air jet design for high per-cent contaminated material, durable and dependent;

* Adopts high-resolution image sensor, equipped with high-speed automatic identifying and analysing system;

* New type touch-screen operation platform, big colorful screen and user-friendly operation interface, can easily change sorting precision to the best quality;

* Adopts latest software, highly precise sorting, with low product loss;

* Except for some traditional functions like double-face sorting and second-time sorting, it also has more intelligentized functions, which simplify operation and handle.

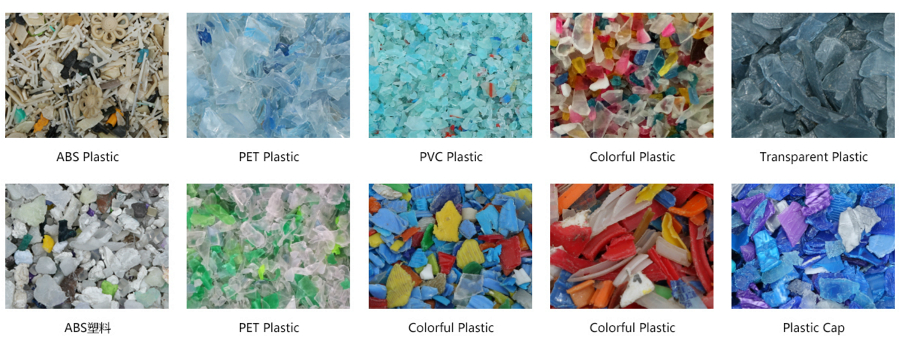

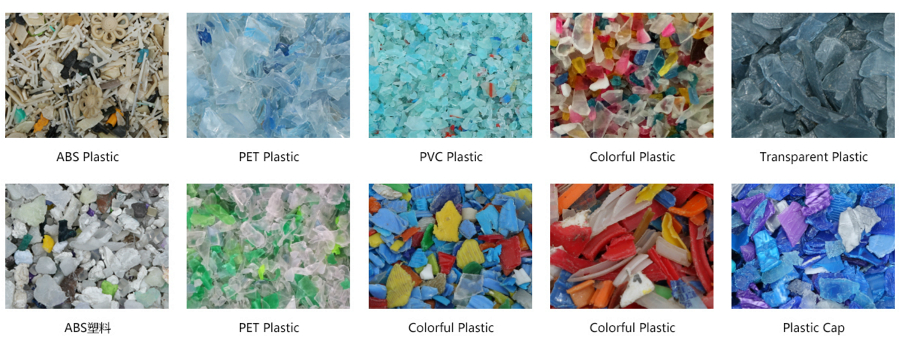

Sorting Examples

* PET bottle flake

* HDPE/LDPE bottle flake

* ABS/PS/PC engineering plastic

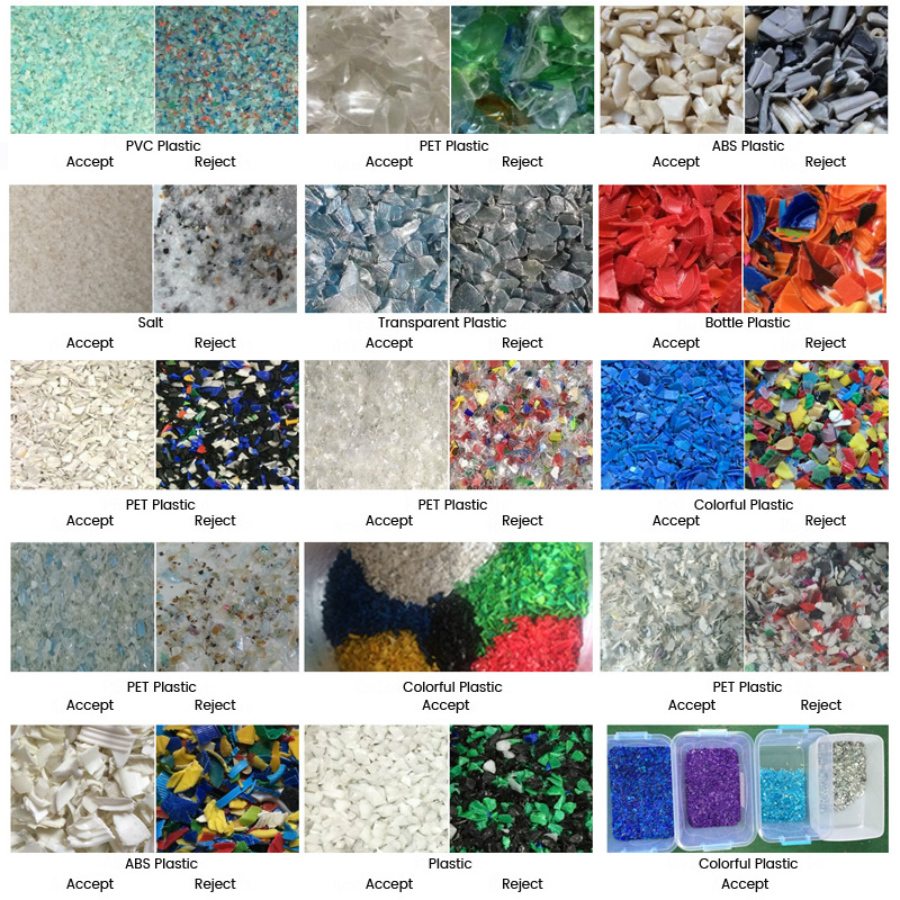

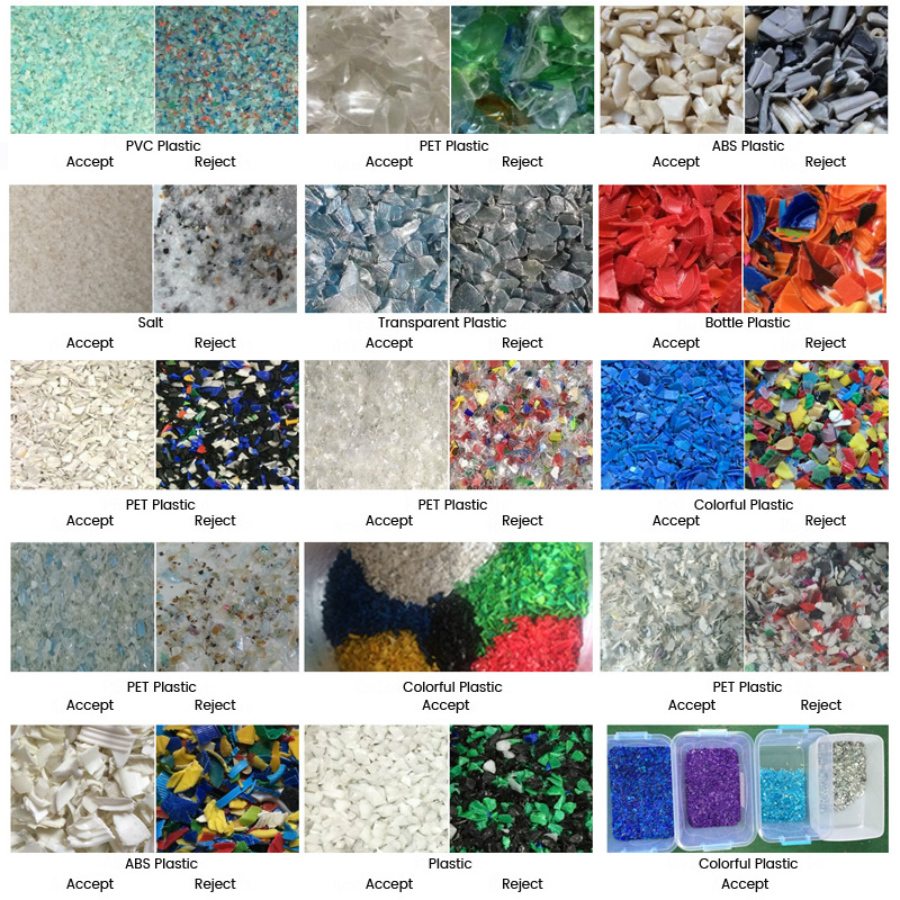

Sorting Result

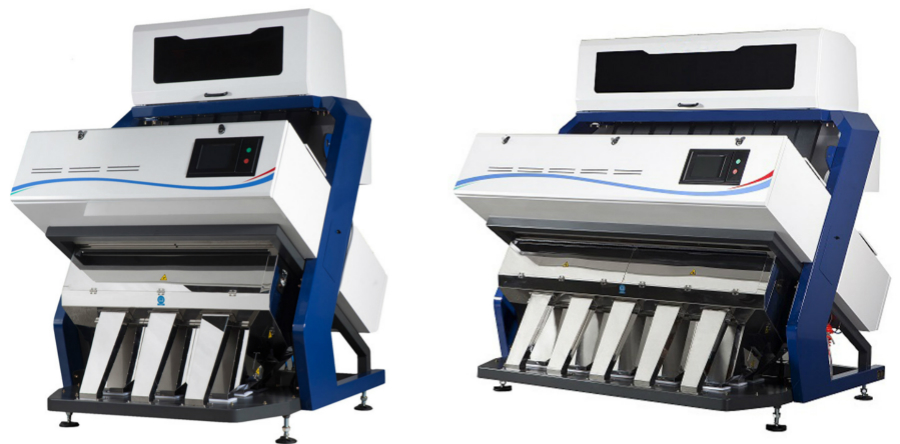

NIR Optical Plastic Sorting Machine Technical specification

|

Model

|

Throughput

|

Material size

|

Power

|

Machine size

|

Weight

|

|

Rock 180F

|

1-3T/H

|

2*2-30*30mm

|

1.8KW

|

1455*1597*2142mm

|

940KG

|

|

Rock 300F

|

2-5T/H

|

2*2-30*30mm

|

2.4KW

|

2075*1597*2142mm

|

1330KG

|

|

Rock 420F

|

3-8T/H

|

2*2-30*30mm

|

3.5KW

|

2625*1597*2142mm

|

1650KG

|

Customer Case