Plastic Color Sorter Technical Parameters

|

Name

|

Channels

|

Power of Main Machine(kW)

|

Voltage(V)

|

Air Pressure(MPa)

|

Air Consumption(m3/min)

|

Dimension(LxWxH)(mm)

|

Net Weight (kg)

|

|

CG4

|

240

|

2.6

|

180~240(50Hz)

|

0.6~0.8

|

≤4.0

|

1765x1570x2143

|

1050

|

|

CG6

|

360

|

3.2

|

180~240(50Hz)

|

0.6~0.8

|

≤5.5

|

2400x1570x2143

|

1450

|

|

CG8

|

480

|

3.6

|

180~240(50Hz)

|

0.6~0.8

|

≤6.5

|

2950x1570x2143

|

1800

|

|

CG10

|

600

|

4.2

|

180~240(50Hz)

|

0.6~0.8

|

≤8.0

|

3700x1570x2143

|

2200

|

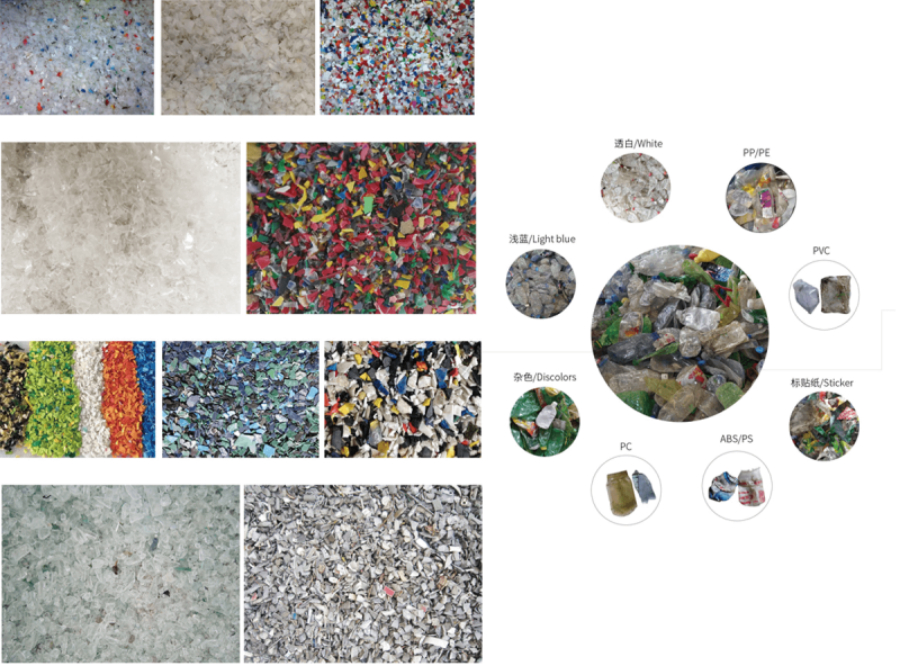

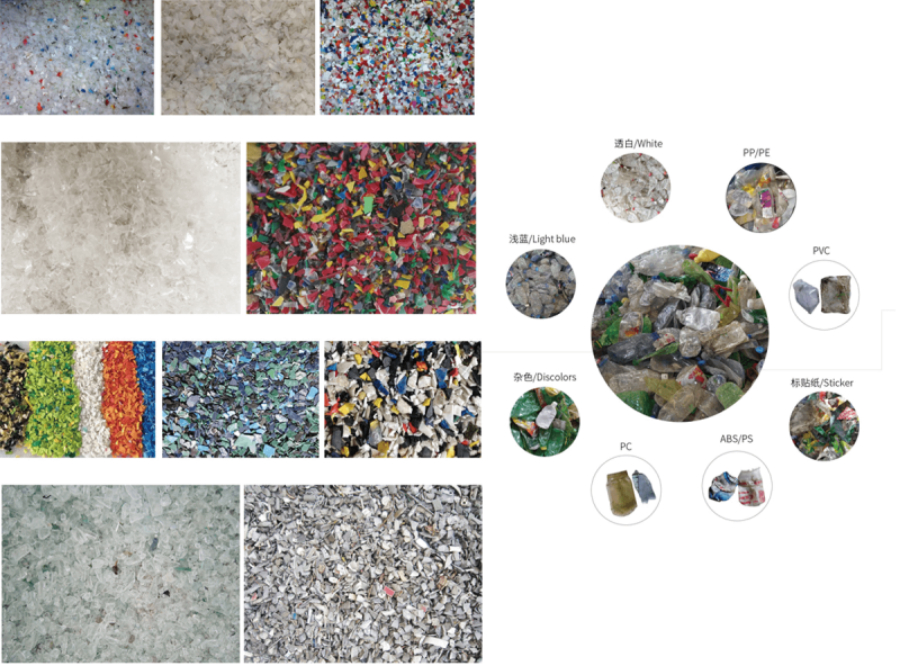

Examples of Sorting

Plastic Color Sorter Advantages

Super Brain

According to the characteristics of the material matching, using professional self-learning and one-key automatic technology for achieving a "fool" operation.

True Color Micro Camera

Using CCD sensor technology, with HD & low distortion industrial lens which can scan material over 30,000 times in one second, micro level identification.

Point-point Clean System

Individually configurable cleaning system for each channel, with 3 times interval cleaning than other common color sorter machine.

High-Speed Ejector

Magnetically levitated high-speed ejector can completely match the whole machine, with a long using life by using Meyer unique technology.

Stepless Dimming

Complementary Stepless Dimming According to the environmental change of sorting material and automatically adjusting the brightness output with adaptive technology.

Soft Landing System

According to the design of system dynamics ensuring the soft load for material, reducing the probability of a rebound, fragmentation & loss of materials.

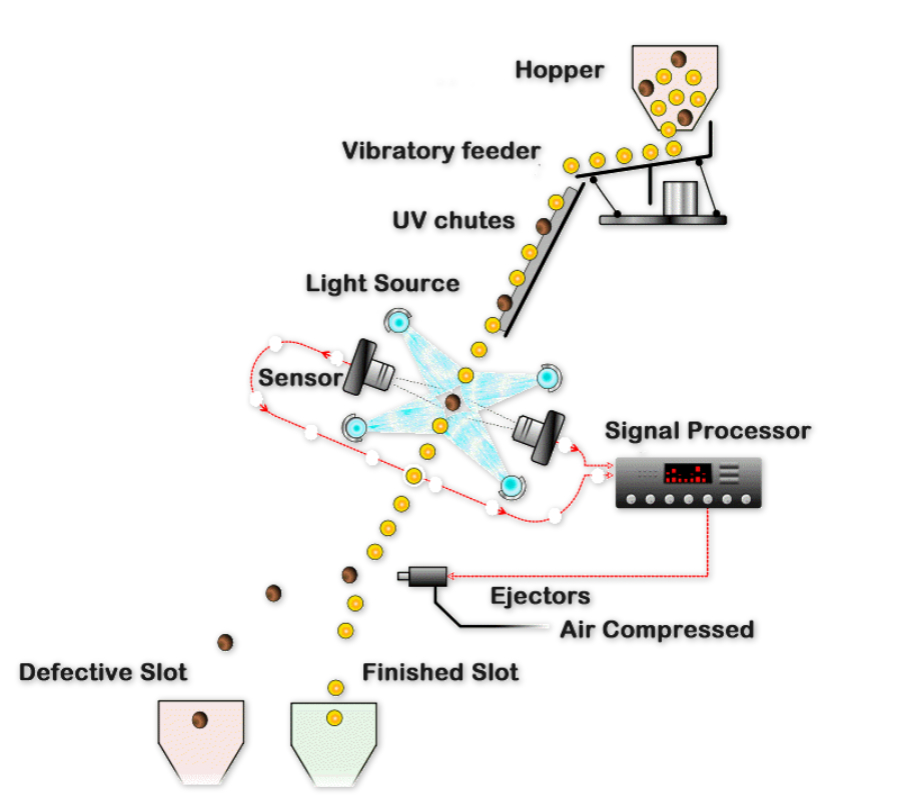

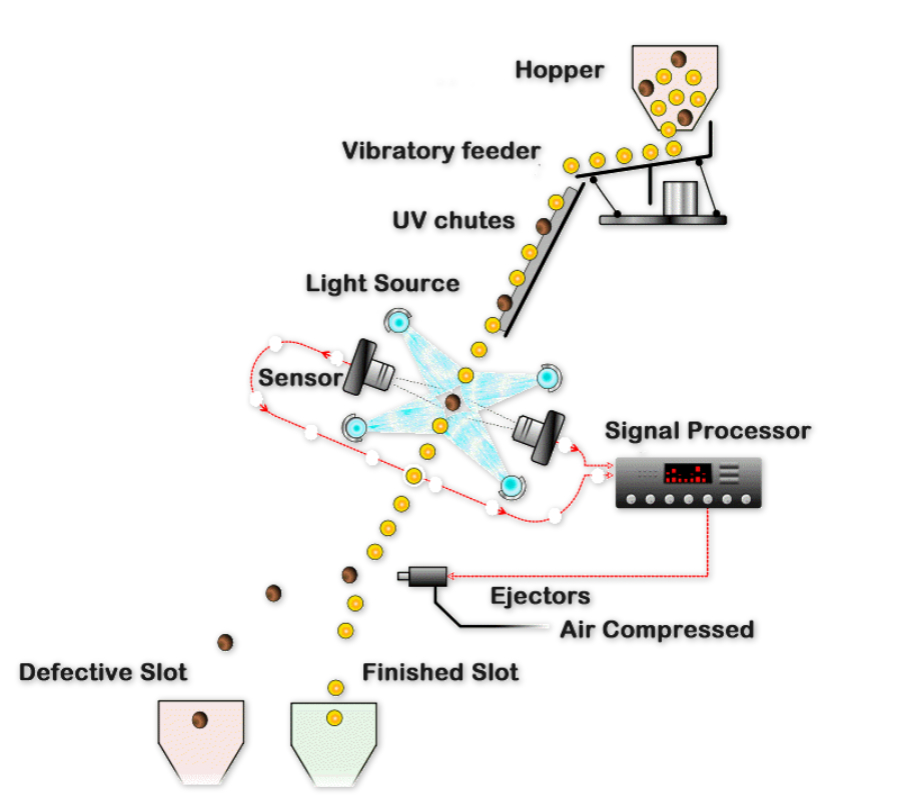

Plastic Color Sorter Working Principle

1. Raw Material are put into the machine from its feeding hopper on the top.

2. Vibrated by vibration device and sliding along material chute into the zone of observation in sorting chamber through sensor and background plate .

3. Under the effect of light source, CCD sensor receives compound light from materials being sorted.

4. According to the light intensity and color changes, make the system produce output signal and drive solenoid valve to work ,ejecting the discolor grain to defect chamber and good materials continue to fall into the finished goods chamber.