Optical Plastic Sorting Machine Sorting Removal

* Black specks

* Spots

* Foreign material

* Discolorations

* Dye drops

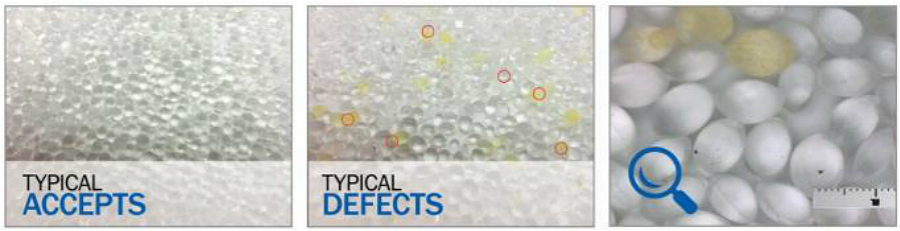

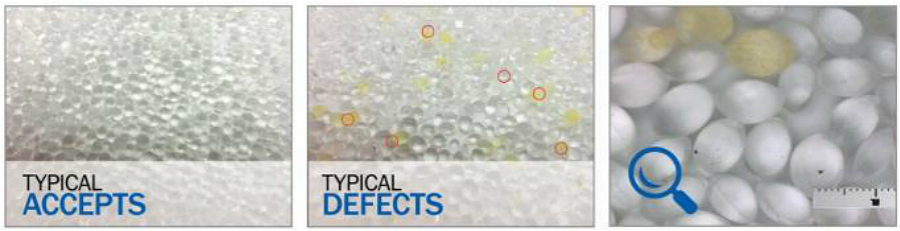

Reject: Yellows and subtle dis coloured pellets

Reject: Spot Defects.

Reject: Transparent & dis coloured pellets.

Optical Plastic Sorting Machine for plastic flake

Advanced sensor-based sorting technology for optimized results

Plastic flake sorting: Consistently exceptional quality

Your challenge:Achieving high purity highest purity pet flakes intended for the production of new transparent bottles must offer purity higher than 99.99% (<100 ppm). Anything less could prevent the use in bottle-to-bottle applications.

Our answer: Achieve high purity – continuously automatic sort flake analyzes and sorts flakes precisely by color and material, including metal. By combining a field-proven mechanical setup with advanced sensor technology to ensure precise sorting for even the smallest grain size.

The solution: Seamless and flexible

Plastic flakes are screened into grain size fractions of 2 and >2 - 12 mm.

The RC flake detects color (transparency) and material (eg: Pvc, colored pet, pe, pp, ferrous and non-ferrous metals… Etc.) of the fine particles all at the same time, ejecting impurities and undesirable colors.

The result: Pet with extremely high and constant purity (<100 ppm for a global contamination) with very low material loss (<1%), meeting the requirements of bottle-to-bottle & sheet recycling.

Optical Plastic Sorting Machine for Plastic Scrap

Optical Plastic Sorting Machine Advantages

1,Advanced image acquisition system

Use the high resolution CCD camera with high quality industrial lens to achieve clear and accurate image acquisition .The camera could capture the micro defects of material instantly.

2,High reliability

Use high signal-to-noise ratio sensor and anti-interference circuit system,which could highly improve stability and reliability.

3,Intelligent image processing algorithm

Color sorting algorithms of gray level,color difference and HSV are perfectly combined with shape sorting algorithms of size,circular degree,texture etc,and successfully solved a series of high difficulty color sorting problems,and dramatically enhance the sorting accuracy.

4,Unique chutes processing technology

The special anodizing and hardening technology can greatly improve the channel smoothness and ware resistance to guarantee high production.

5,High quality solenoid valve(ejector)

Equipped with high quality solenoid valve.The valve has longer lifespan ,high frequency ,and low air consumption.The working frequency is 1000 times per second,which guarantees the accurate and perfect

ejecting.

For the different sizes and characteristics of material particle, Bird Machinery optical sorters use the solenoid valve of different sizes.

6,High efficiency and reliable light source

Advanced LED lighting technology with advantages of super high intensity,long lifetime and perfect performance.

7,Simple operation, easy to learn and use

Simple optical system design, precise automatic correction system, combined with the well-designed human-machine interface to simplify the complexity of machine commissioning and use.Our machine is intelligent so it can learn by itself.Our machine can take a photo of the material and then the machine could set the parameters by itself.