Technical Parameters

|

Model

|

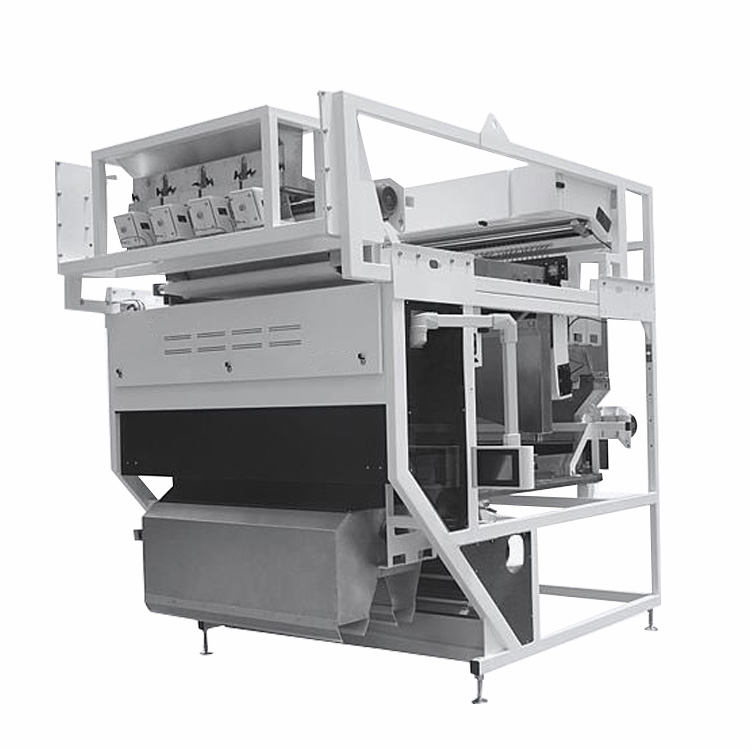

MOCS1280-D Ore Color Sorter

|

|

Layer No.

|

Double

|

|

Output (T/h)

|

1-3cm

|

6-12

|

|

3-5 cm

|

8-15

|

|

Carryover (bad: good)

|

≥40:1

|

|

Accuracy (%)

|

≥99%

|

|

Voltage (V/Hz)

|

220V/50HZ

|

|

Power (Kw)

|

2.4-4.0

|

|

Air pressure (Mpa)

|

0.6-0.8

|

|

Consumption (L/min)

|

3800

|

|

Weight (Kg)

|

2000

|

|

Dimensions (mm)

|

3584*2222*2960

|

Remarks: The above color selection parameters are based on quartz sand containing 10% of impurities. The yield will vary according to the impurity content of the raw materials.

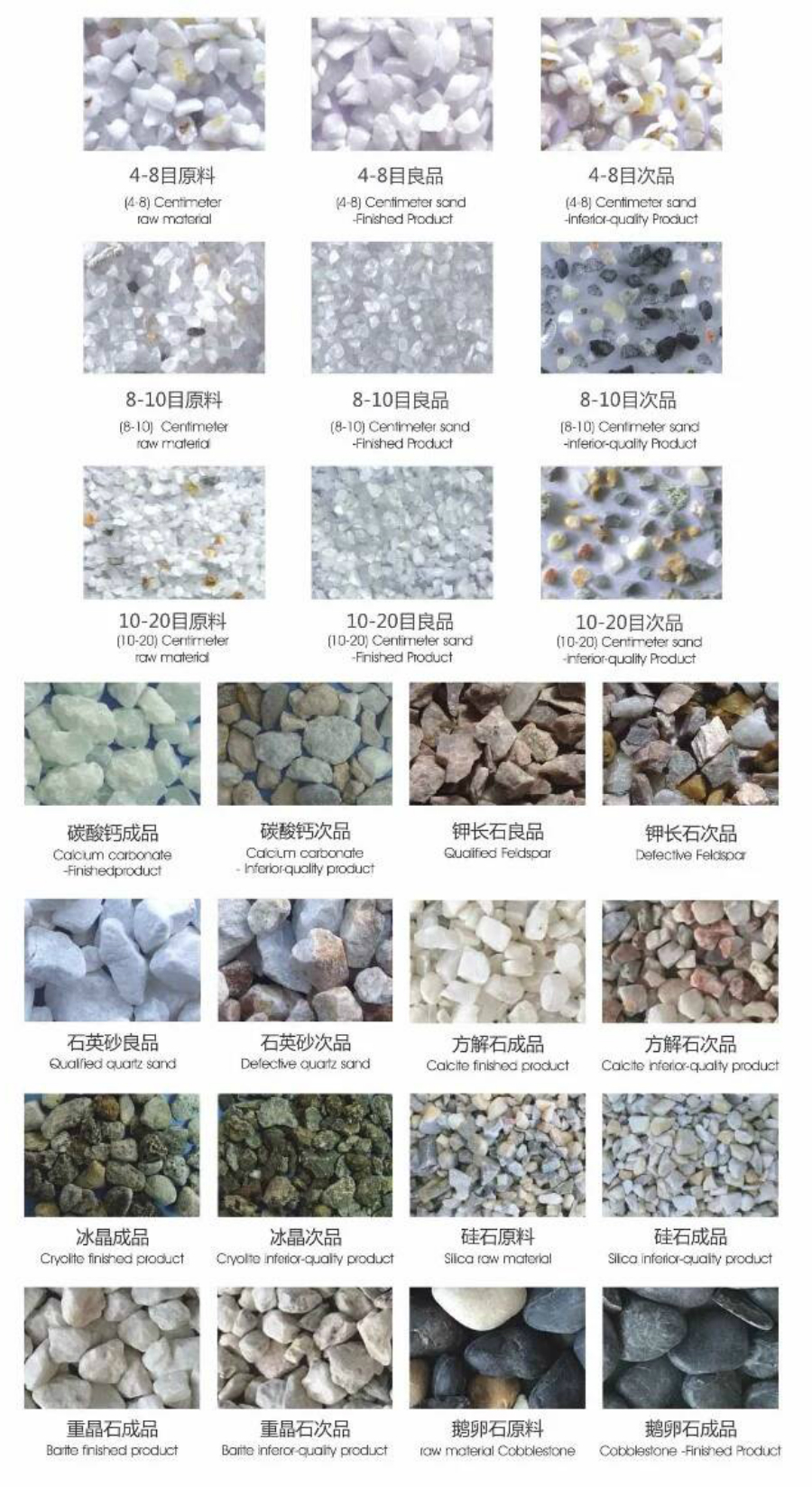

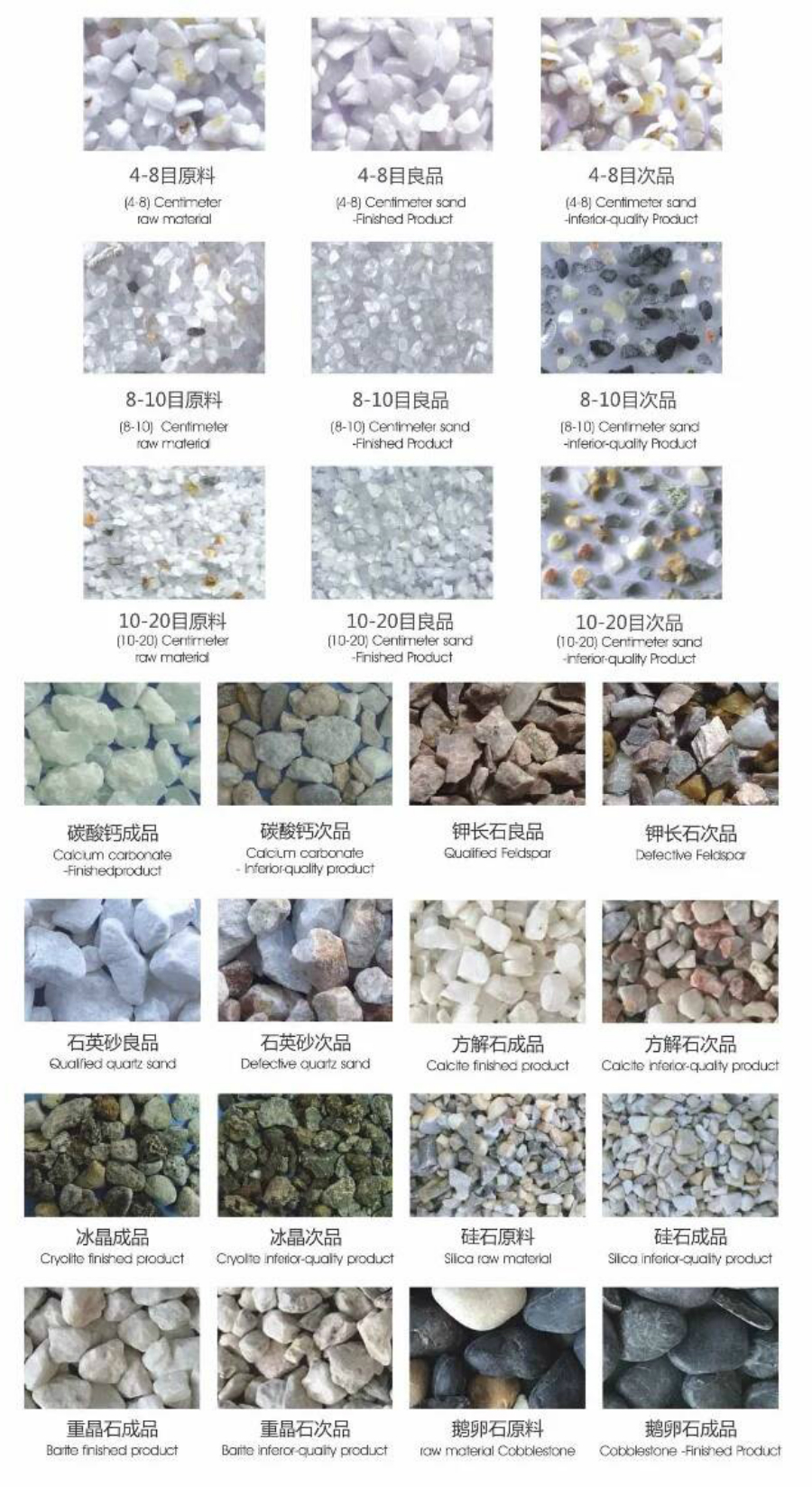

Examples of Sorting

Ore Color Sorter Application Area

* Non-metal Ores Sorting

Potassium feldspar, quartz, talc, phosphate, calcite, dolomite, andalusite, fluorite, vermiculite, mica, bentonite, kaolin, barite, feldspar, quartz, calcium carbonate, pebbles, cryolite, garnet, limestone, manganese ore and so on.

* Nonferrous Ores Sorting

Copper, antimony, mercury, lead, zinc, tin, nickel, magnesium, cobalt, aluminum, bismuth and silica and so on.

* Precious Metal Ores Sorting

Gold, silver, zirconium, tungsten, molybdenum, tantalum and niobium and so on.

Ore Color Sorter Function & Features

First, The Core Technology

1. New LED light source system

Designed with intelligent LED optical system, intelligent light control flexibly switches the color of the backlight and uses a concentrating mirror to prevent LED astigmatism.

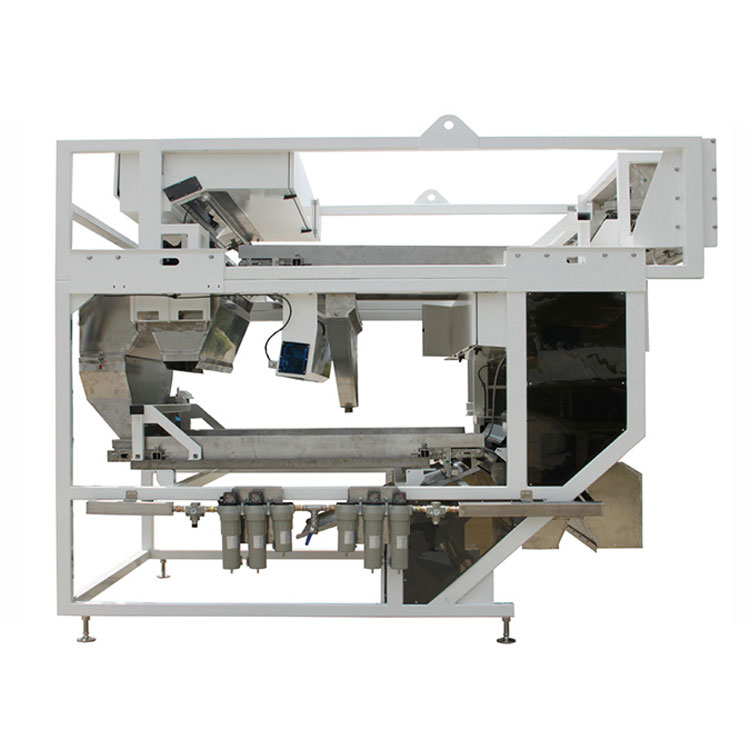

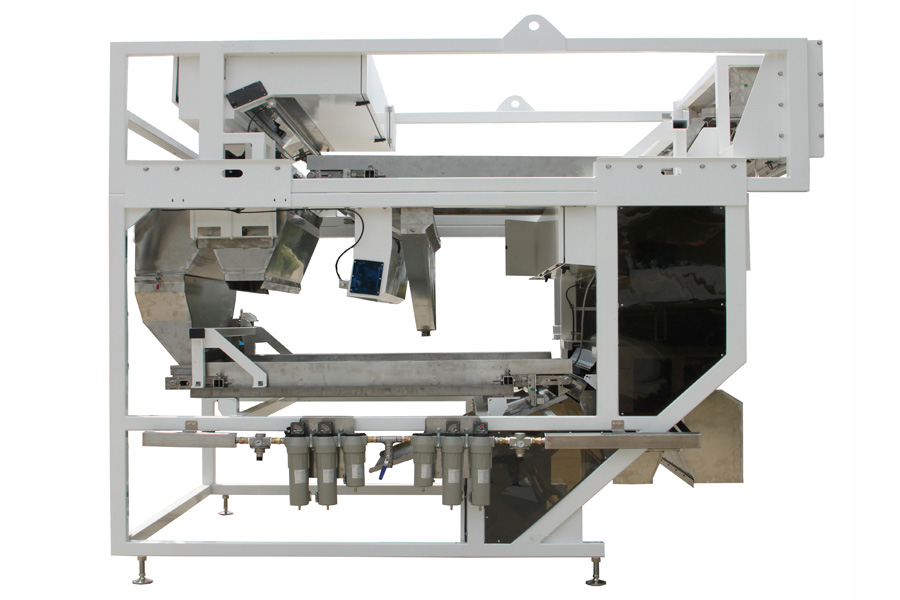

2. Feeding conveyor system

For the characteristics of large, small, dry and wet ore particles, slow, fast and free fall conveying is adopted to ensure uniform feeding.

3. Image acquisition system

The high-definition full-color far-spec lens is used to realize the comprehensive acquisition of materials (RGB) red, green and blue, and to deeply identify small and fine ordinary color sorters that cannot be selected.

4. Image processing system

High-end full-color line scanning technology, DSP+FPGA leading edge processing technology, CCD reaches 5400 points X10K scanning capture, color and shape combined with multiple modes intelligent complex algorithm, providing "color selection + shape selection + penetration" for different ore materials Program.

5. Solenoid valve

It adopts special solenoid valve for ore, with high frequency, accurate color selection, high efficiency and energy saving, and intelligent selection of different sizes of ore particles.

6. Cloud object system

Autonomous cloud control, cloud computing technology, online operation, online monitoring, online services, free upgrades.

7. Custom sorting structure

Different ore sorting requirements, the introduction of a single layer double layer, single vision double vision and other models combination; two-layer structure can achieve the upper layer of sorting materials, can be re-selected to the lower layer, the color selection accuracy is higher.

8. Automatic dust cleaning system

Add automatic dust removal and automatic spray cleaning system devices. It can be built according to the output of special mines to ensure the stability of the sorting effect.

Second, The Functional Characteristics

1. Solve the problems of ore bonding, ore and track bonding in the process of wet ore sorting.

2. The selection range is from 1 cm to 5 cm, depending on the sorting of large particles, wet ore.

Products Show