Product Description

Belt Color Sorting Machine: The material after color separator of a port (bin) smooth transfer to another port (outlet), outlet is equipped with high speed camera acquisition card, material after industrial camera collection, in the end of the color separator will be color difference bad material separation of impurities. The entire process, track color separator will play a role of the color to choose. Caterpillar color separator can be divided into double track color separator and single track color separator.

Belt Color Sorting Machine can be extensively used in foodstuff, oil, chemistry and pharmaceutical industries etc. especially suitable for fine sorting of grain material e.g. seeds, salt, cashew nuts, peanuts, beans, raisin and dehydrated vegetables etc.

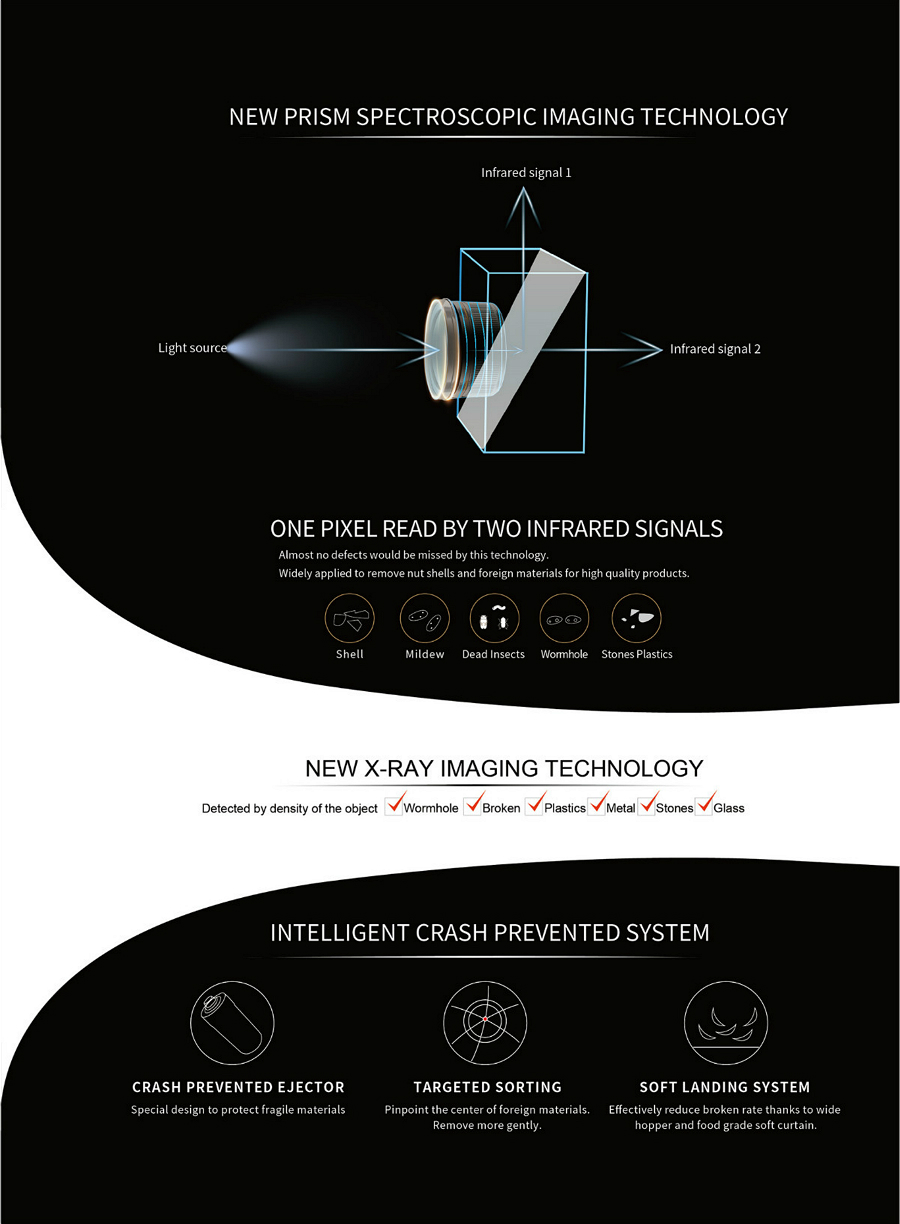

Belt Color Sorting Machine can dramatically reduce percentage of damage. It equipment with dual view cabinets and customized light resolution camera assembly can be installed for special material The latest 3 linear color CCD camera and FPGA processing system in addition to the high-speed electromagnetic ejector have been adopted in the machine, and also the multi-color touch screen has been installed therein, so it is a high-tech product combined with technology of optics, electronics and pneumatic. NIR is an optional device. The machine can automatically reject contaminant or colored grains, featuring high sorting accuracy, great efficiency, simply operation, easy maintenance, compact structure and elegant appearance.

Main Features

-

Advanced Vision System

-

High sensitivity, high resolution CCD camera to detect tiny defects

-

Special camera lens to minimize image distortion on edges

-

High speed digital image processing to identify defects with weak color contrast

Proprietary Sorting Software

-

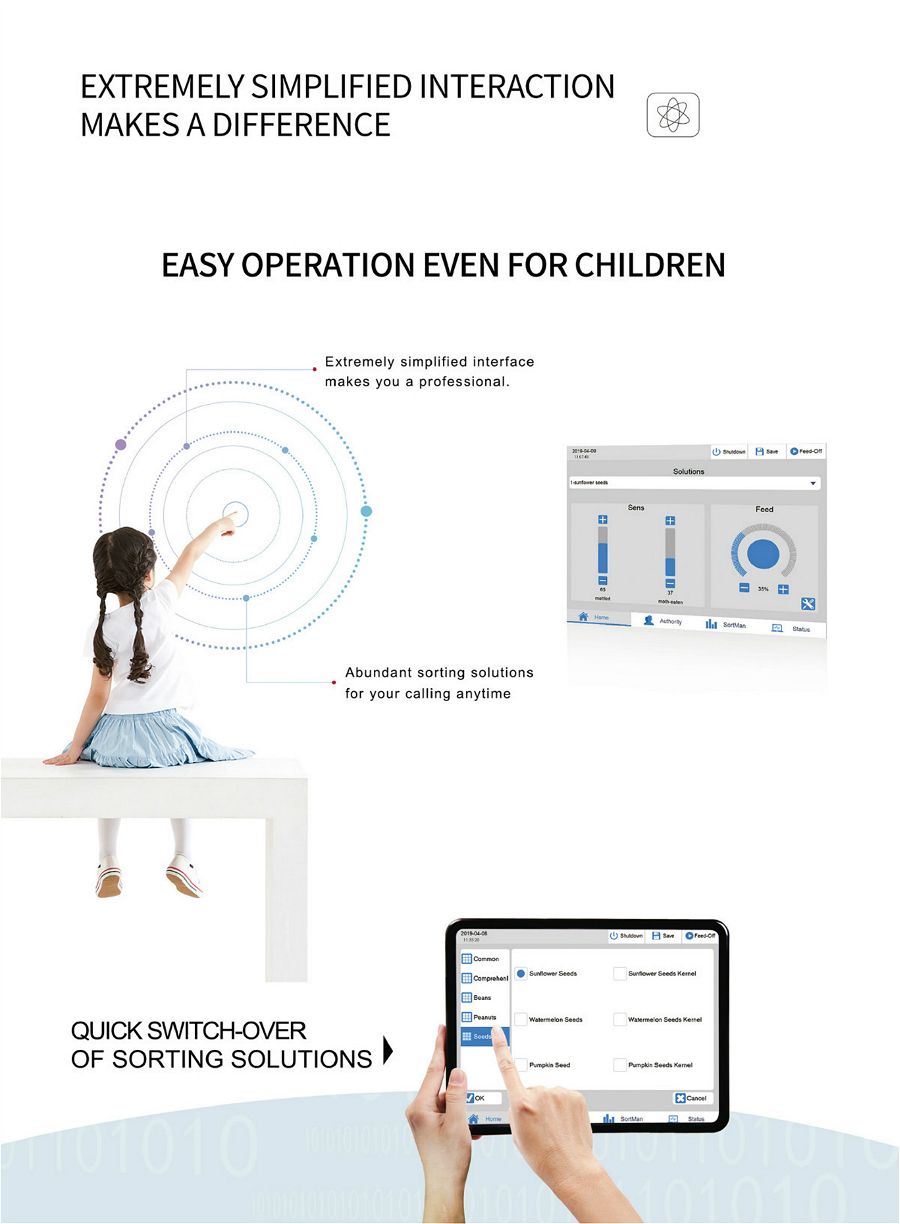

Sophisticate defect processing algorithms with customized color model to enable precise defect identification

-

Contrast Recognition Model to automatically adjust sensitivity when sorting environment changed

-

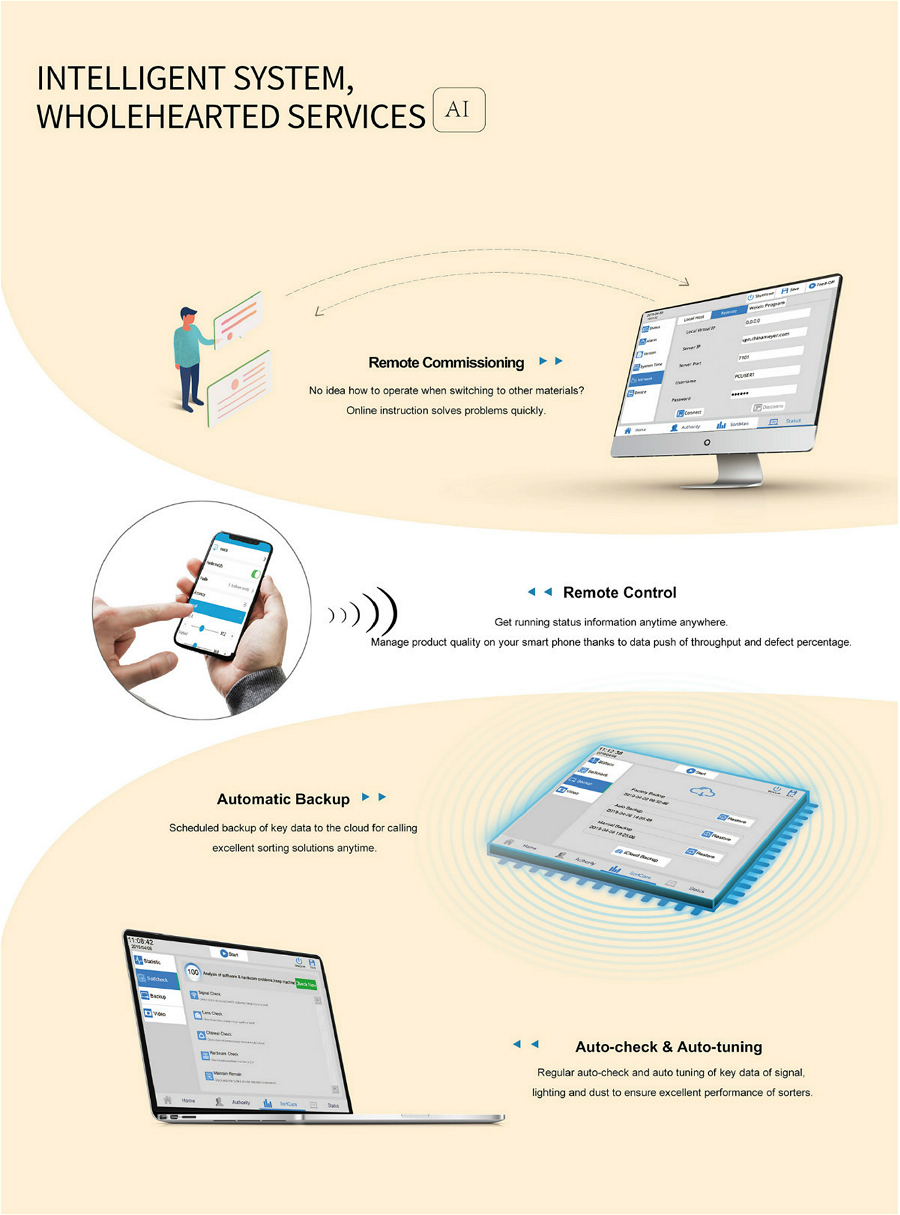

Live monitoring of machine status, alarms on faults

-

Multiple sorting modes to reduce time for product change over

-

Easy software/firmware upgrade with USB

Stable Feeding

-

Belt feeding to ensure stable product flow

-

Predictable speed of product at scanline to achieve accurate ejection

-

Accurate Ejection

-

Specially designed ejectors with fast response

-

Long ejector life

-

Easy for maintenance

Technical Support

-

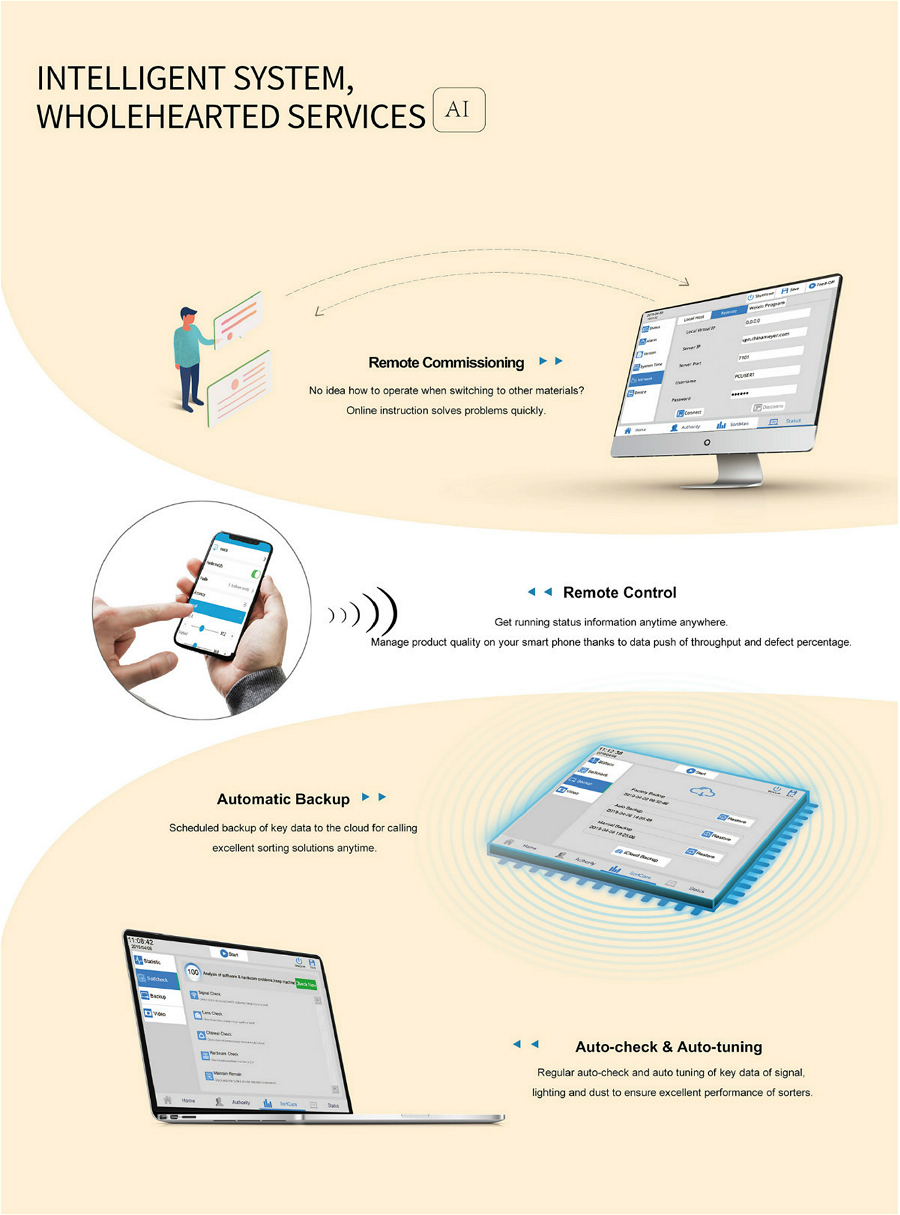

Remote troubleshooting & software upgrade

-

Supported by experienced technical team

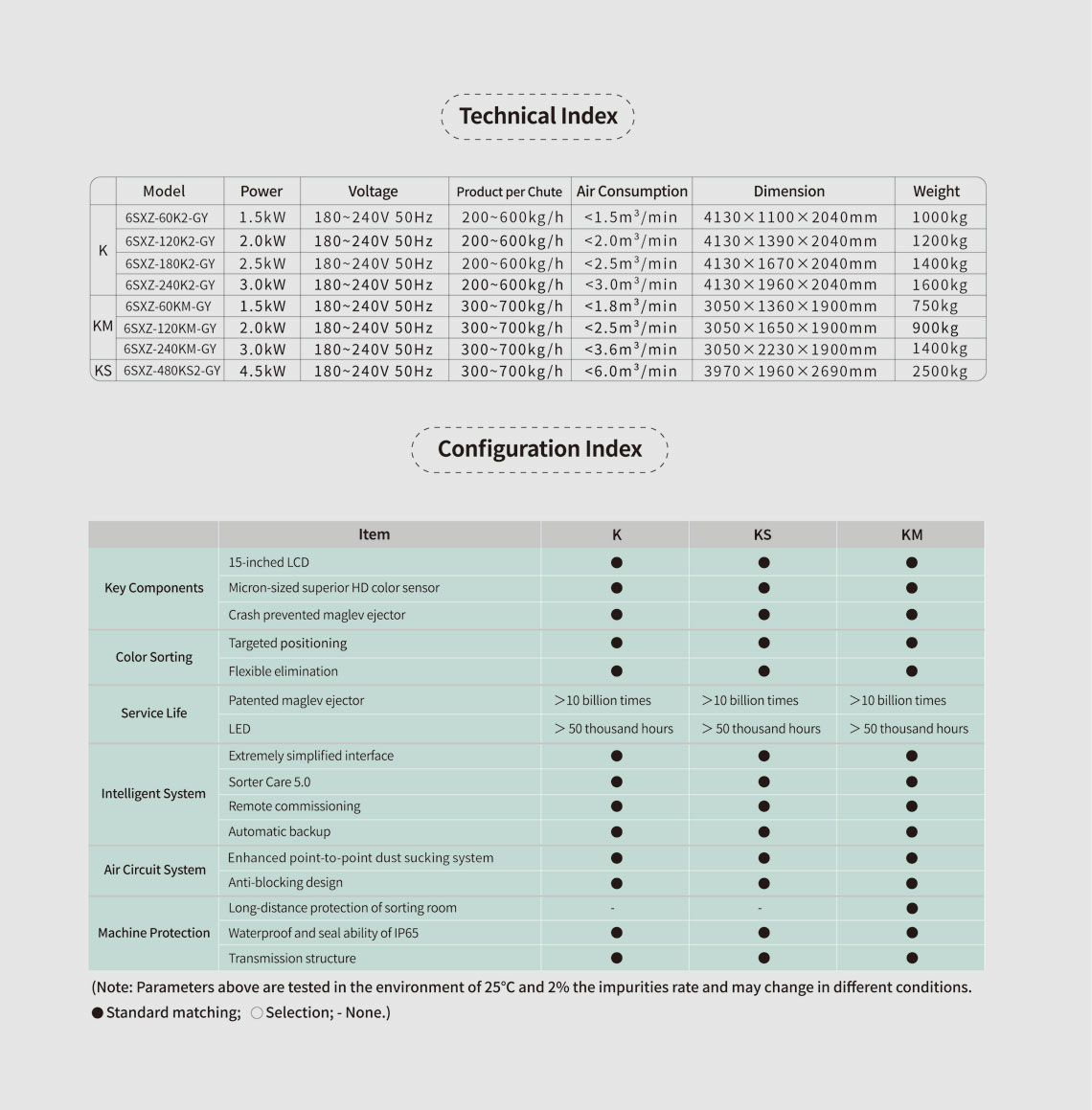

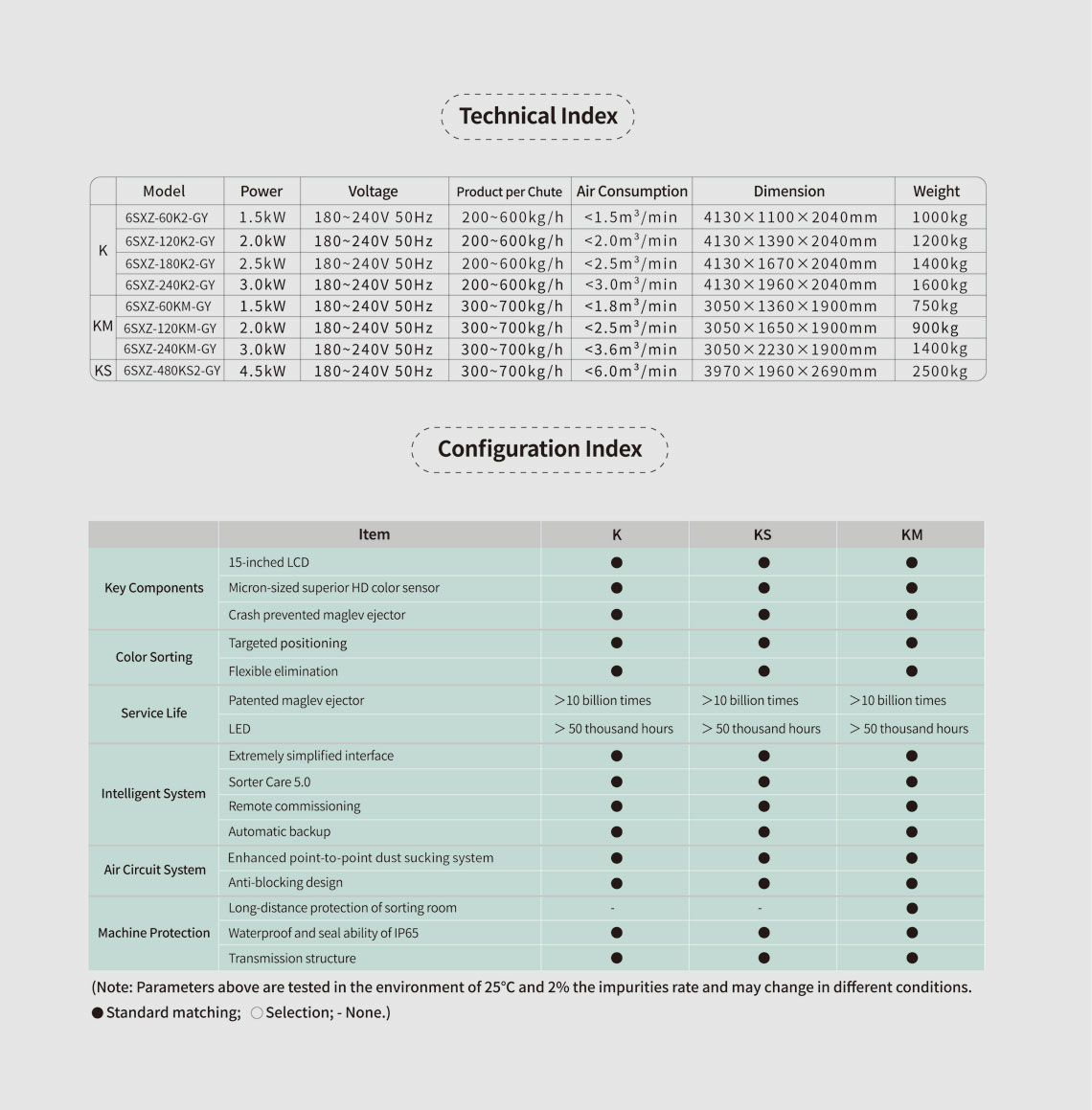

Belt Color Sorting Machine Technical Parameters

Examples of Sorting

Belt Color Sorting Machine is suitable for applications in food processing companies of nuts, seafood, fresh cut vegetables, dried fruits, dried fruits, fresh fruits, freeze-dried fruits and vegetables.

Belt Color Sorting Machine Technology Features

1. High-definition CCD Image Sensor

5400 pixel HD full color CCD is adopted, the definition is up to 0.08mm2, which ensures recognition of subtle color difference and minimal flaws.

2. High-speed data processing, real time display of real image

High-speed parallel data processing chip, real-time high efficiency image capture and processing system of the machine increased working efficiency of color sorter greatly.

3. High Quality Image Processing Algorithm

International advanced image processing technology is applied, which can recognize subtle color difference as small as 0.1mm. Higher color sorting accuracy, lower sorting carryover.

4.Self-adaption Temperature Control

The fan in the machines elf-adapt working temperature to ensure the color sorter keep normal working in high-temperature environment.

5.Advanced High-Pressure valve Ejectors

Outstanding sorting accuracy make sure to sort out good material and bad material perfectly;high definition and well-designed ejectors; high frequency, high frequency,durable,long service-life.

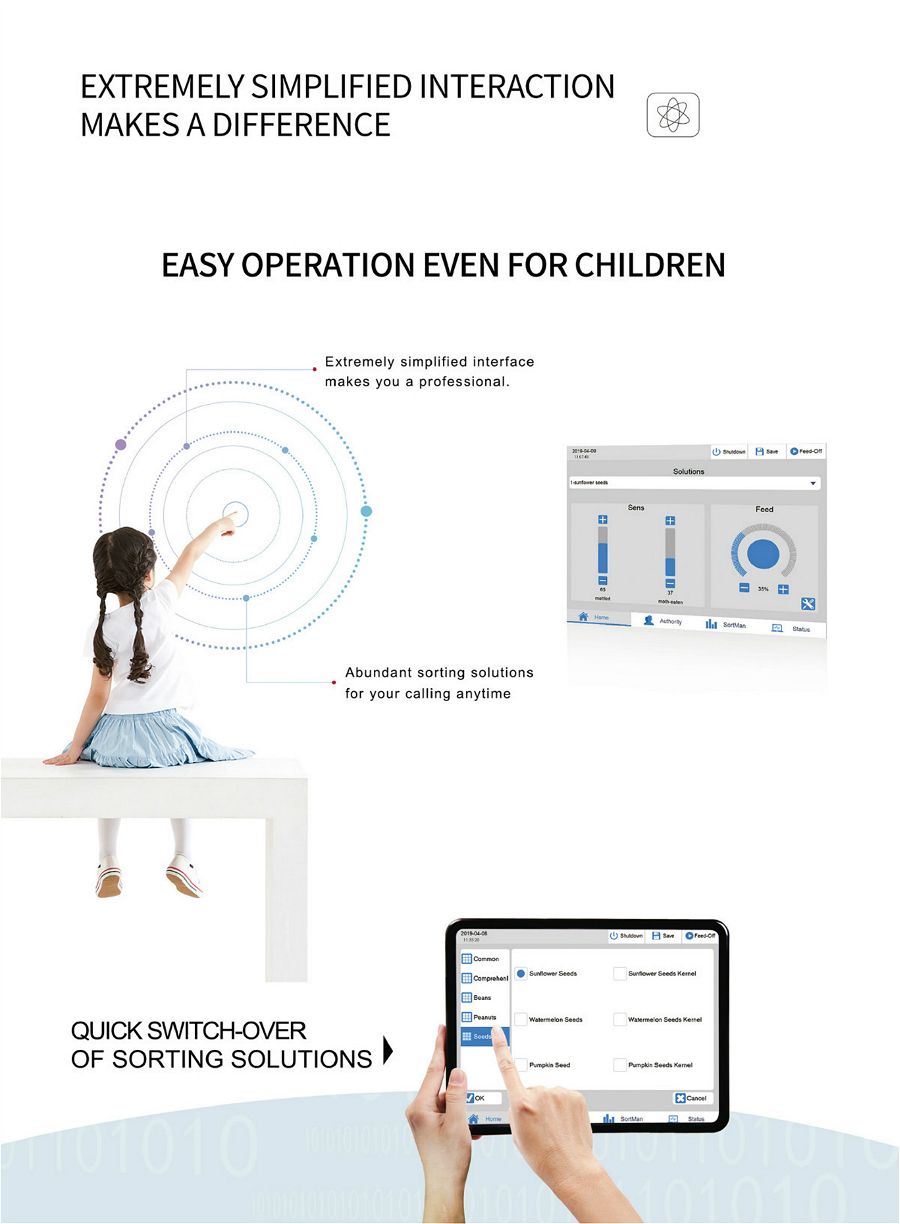

6.Special PC interface display and Operation Platform

User-friendly operation interface ensures convenient operation and processing.

7.High Quality Material Convey System

Food-grade conveying belt with high quality is applied, which ensures the safety of food material, and decreased damage of food product.

Belt-type color sorter machines break a smaller percentage of material (important for nuts) and the product stays relatively static during the transport process as it moves horizontally on the belt. Whereas in the chute type, material slides on the chute because of gravity, causing collision, friction, and larger vertical movements, thus worsening the ratio of broken material. The belt structure makes the transmission smooth and stable without bouncing of material.

8.Special Lighting System

Special light source is equipped to ensure HD image quality, which makes the machine can meet different kinds of sorting requirements and recognize subtle variation of color.