METKEY Chute Color Sorter is available with 1 to 12 chutes customization. METKEY provides high performance with single-layer color sorter and multi-layer color sorter.

Application

Such as: Rice, Wheat, Corn, Soybean, Peanut, Sunflower seeds, Waltnut, Almond, Quinoa, Salt, Medlar, Pistachio, Kidney bean, Chili, Red bean, others.

Plastic materials:

Such as: Waste Plastics, Plastic pellet, Plastic pieces, Plastic granule, Plastic bottle cap flake, PET bottle scrap, ABS plastic flake, PP plastic scrap, Recycled plastic, others.

Mineral materials:

Such as: Quartz stone, Quartz sand, Potassium feldspar, Barite, Calcite, Limestone, Pearl, Marble and others.

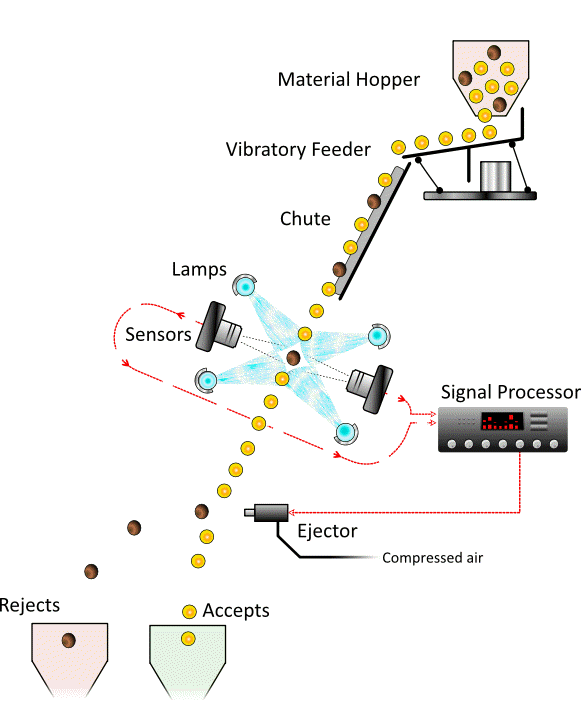

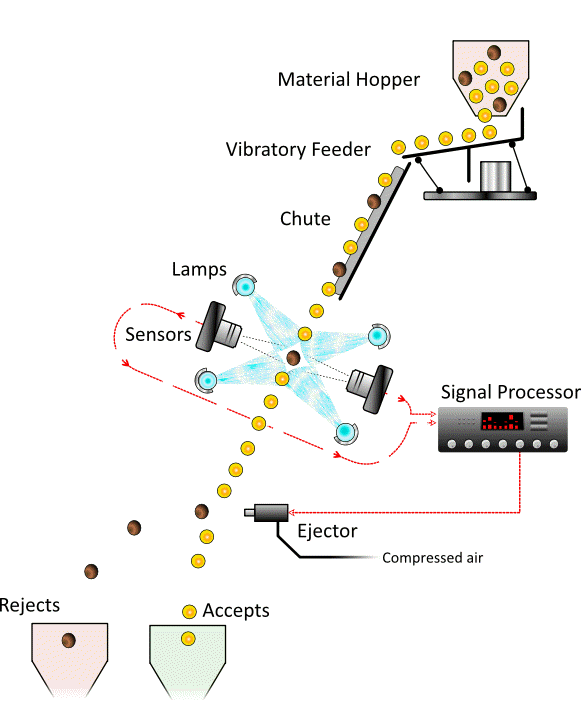

Graphic: METKEY Chute Color Sorter

Specifications:

|

Model

|

Ejectors

|

Capacity(T/H)

|

Carryover rate

|

Accuracy

|

Voltage

|

Power(KW)

|

Weight

|

Dimension

|

|

PM1

|

64

|

0.5-3

|

>10:1

|

>99.9%

|

220V/50HZ

|

0.3-0.5

|

240

|

974*1550*1400

|

|

PM3

|

192

|

1.5-9

|

>10:1

|

>99.9%

|

220V/50HZ

|

0.4-0.65

|

500

|

1554*1707*1828

|

|

PM4

|

256

|

2-12

|

>10:1

|

>99.9%

|

220V/50HZ

|

0.7-1.1

|

800

|

1869*1707*1828

|

|

PM5

|

320

|

2.5-15

|

>10:1

|

>99.9%

|

220V/50HZ

|

0.7-1.1

|

1000

|

2184*1707*1828

|

|

PM6

|

384

|

3-18

|

>10:1

|

>99.9%

|

220V/50HZ

|

1.1-1.9

|

1100

|

2500*1707*1828

|

|

PM7

|

448

|

3.5-21

|

>10:1

|

>99.9%

|

220V/50HZ

|

1.1-1.9

|

1350

|

2814*1707*1840

|

|

PM8

|

512

|

4-25

|

>10:1

|

>99.9%

|

220V/50HZ

|

1.3-2.2

|

1500

|

3129*1710*1828

|

|

PM10

|

640

|

5-30

|

>10:1

|

>99.9%

|

220V/50HZ

|

1.4-2.3

|

1750

|

3759*1710*1828

|

|

PM12

|

768

|

6-35

|

>10:1

|

>99.9%

|

220V/50HZ

|

1.4-2.3

|

1900

|

4389*1710*1828

|

METKEY Chute Color Sorter has two main functions of sorting and grading.

The sorting function is designed to diagnose the defective, broken, and deformed objects from the raw materials and then get the classified products.

The Grading Function is required for fine screening. For example, Tea and Coffee beans.

People who prefer tea have big requests for top-level tea leaves, and this function could quickly grade the tea based on color, weight, size, shape, etc.

Performance

There is a wide range of sorting capabilities for different products, and every chute generally has 0.2~3t/h sorting capability according to different materials.

Graphic: Chute-Type Color Sorters in the warehouse

The color sorting accuracy is not less than 99% and the carryover rate(bad: good) around 10:1.

METKEY develops various types of color sorters to match different markets’ requests.

For the United States, the rated voltage is 240Vac. And in Europe, it is 220Vac. Besides, METKEY Color Sorter is available for the voltage of 380V and 415V.

There are two different sorting modes for practical product processing: Normal Sorting and Invert Sorting.

Both sorting methods are used to separate quality objects from the raw mixture.But there is a little difference between these two modes.

Normal sorting mode is suitable for materials with a small proportion of impurities and defects. However, the reverse sorting mode is better for materials with a large percentage of impurities and defects.

The two sorting modes can work individually. Also, they work together.

METKEY Chute Color Sorter has two typical structures:

single layer color sorter

multi-layer Color Sorter.

Multi-Layer means many sorting modes and a bigger sorting capacity.

Each layer may have one or more independent sorting groups, and each sorting group could select a specific sorting mode.

Therefore, Single layer Optical Sorter could only separate the impurities and the right things at one time. but the multi-layer color sorter could do twice sorting.

That means the multi-layer structure could separate the mixed grains but also grade the fine products.

METKEY Chute Color Sorter is easy to operate.

There is a built-in humanized operation panel in the sorting machine. METKEY optimizes the operational flow to make it more logical.

On the hardware, the optical sorting machine uses original American chips. It can guarantee the long-term stable operation of the device.

A network control module is available as well, and it supports TP/TCP protocol. Let Color Sorter connect to the internet, and you can easily control the machine through your smart devices such as iPad, iPhone, and Android phones.

Technology

One machine = 100 labor

METKEY Chute Color Sorter has both unique image correction technology and full-color screening technology.

This unique image correction technology, also called non-linear aberration correction technology, can automatically correct the non-linear images because of distortion and aberration caused by signal errors during image collecting.

METKEY Chute Color sorter usually separates the raw material according to RGB color difference. And it adds another camera to collect image saturation information. Both these unique technologies can raise the accuracy of sorting.

METKEY chute color sorter is an automatic tool with a CCD camera and integrating light. It uses the high-tech photoelectric diagnostic system to classify the heterogenic particles.

How does it work?

Graphic: Color Sorter Working Principle

METKEY Chute Color Sorter is a complete optical sorting system, and every component needs to work together to finish the sorting task.

-

The Raw Material Mixture drops down from the Material Hopper first and passes through the vibratory feeder to enter the chutes.

-

The vibratory feeder can make sure the objects fly to the chute in a line at the same speed.

-

The CCD high revolution Cameras image them, the sensor mounted on the back of the cameras will analyze images and send a message of acceptance or rejection to the chip processor.

-

Finally, ejectors would release the compressed air and change the defective grain’s motion track to separate them from the fine grain after receiving rejection signals from the chip.

Structure

There are about 1000+ accessories for every sorting machine. Following seven main components can help well understand how they work together to finish sorting tasks.

1. Material Hopper

Made of #304 Stainless Steel, the material hopper is the starting point for the entire sorting process. Original mix will enter the hopper and start their sporting journey.

#304 Stainless steel is food-grade material, and it can touch the food directly according to LFGB and FDA standards.

2. Vibratory Feeder

The vibrator adjusts the uniformity of the material drop and ensures the sorted objects evenly arrive at the chutes without any overlap. It is connected to the hopper and chute.

The material falls evenly into the chute, which reduces the proportion of material that is brought out.

3.Chute

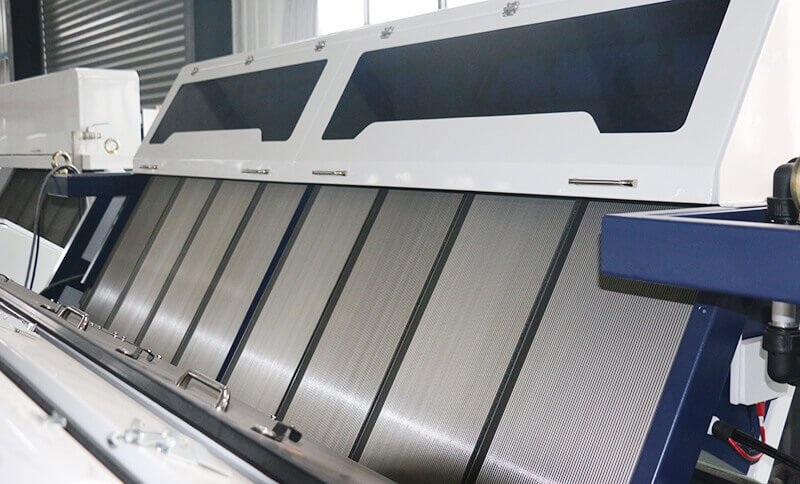

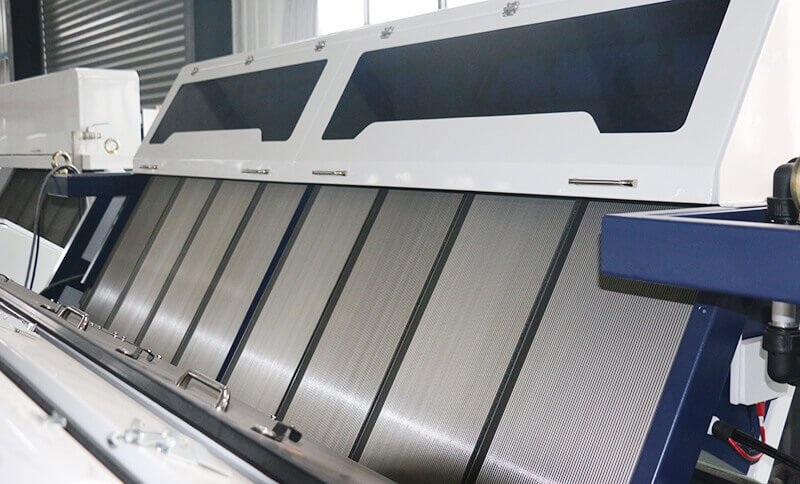

Graphic: Chutes

The primary function of the chute is to give these materials at the same speed. There usually are 64 channels on each chute.

Plenty of objects leave from the vibratory feeder enter the sorting area along with the channels.

On the other hand, a fixed-length chute makes it easy to catch objects and take photos.

During this process, it is necessary to select a smooth and durable channel. A smooth Channel would raise the speed of the grain, and High Speed will affect the sorting capacity.

We also design a dust cover for the chute, which will significantly reduce the influence of external impurities on the sorting process.

What’s more, A tracing heater is available that can mount at the back of the chute. The heater is a benefit for objects drying.

4.CCD Camera with High Revolution Sensor

Graphic: Color Sorter’s Sensor

High-Speed CCD Linear array Cameras take photos for the accelerated objects and the recognition accuracy up to 0.06mm.

Be able to provide HD images as high as 200 million pixels per second.

High Revolution sensor could quickly and accurately recognize the 0.01mm2 defects.

5.LED Light

The LED light provides a perfect fill light for imaged products, and it requires to install in front of the shooting area.

METKEY adds in a row of cold LED light, High luminance, low power consumption, 5k hours long life, which is a benefit for identification.

6.Ejector

Graphic: Ejectors in the semi-warehouse

After receiving the digit signals from the CPU, the ejectors are 1 Billion times. High-Frequency Solenoid Valve responds quickly and releases the compressed air.

The air would change the rejected or accepted products’ movement routes, which separates the bad or good grain from the raw materials.

METKEY selects a powerful and precise nozzle with a 4.75MM port size.

7.Air Compressor and Filter

Air compressor allows providing compressed air continuously. It is always required to work together with an air filter.

And the air filter quickly filters out solid impurities in the compressed air, which helps extend the lifetime of the machines. Besides, it increases the accuracy of the sorting.

How to install and test?

Graphic: METKEY Engineer is Debugging the Machine

METKEY will provide you the installation diagram and operation instruction with packaging.

Every Color Sorting Machine requires a separate metal support platform and material lifting system. The Metal Support Platform will lift the machine to a specific height, which will facilitate the collection of the material at the outlet.

The lifting system is used to deliver the material to the hopper. CE and CSA approve METKEY Chute Color Sorters.

It is a safe and stable color sorting machine. METKEY has a 20-year manufacturing experience as a color sorter, and we can manufacture 500 pieces of Chute Color Sorter each month.

Regularly, we can arrange the delivery in 10 days. Every METKEY Chute Color Sorter is required to do 100% performance testing before packing, which ensures all functions are useful.

Meanwhile, we would organize a professional engineer team to provide free on-site installation, operation training, maintenance, and 24 hours online troubleshooting.

Never stop yourself from contacting us we are here to provide the best solution for your business.