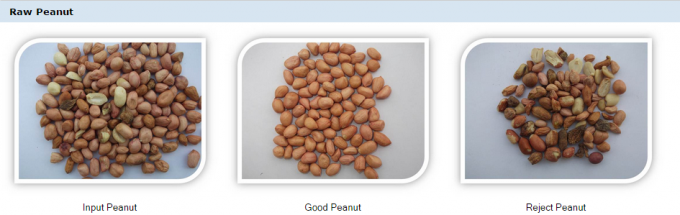

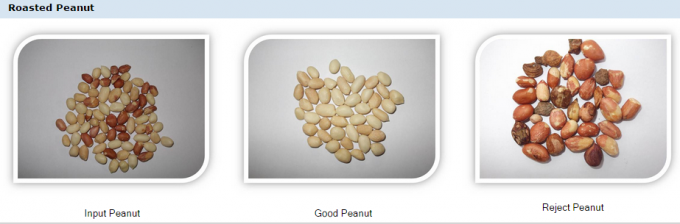

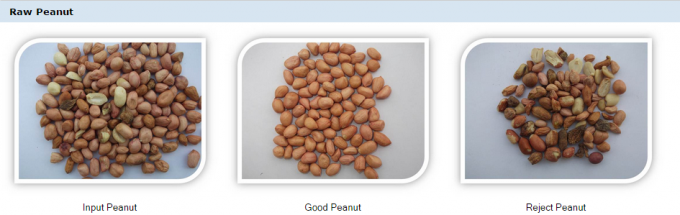

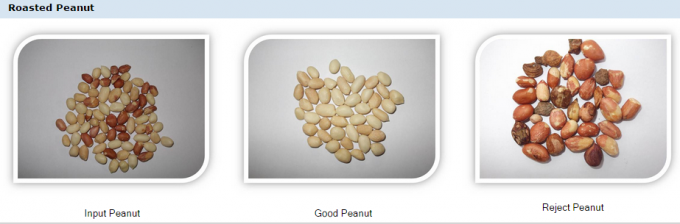

METKEY Peanut CCD Color Sorter are able to sort white peanuts ,red peanuts ,peeled peanuts and peanut in shell,raw,balanched and roasted peanuts.The machine can detect and remove visible defects such as stones,grass,nut grass,stalks,stems,raisins,shells,discoloration,soy,bones,wood,corn,glass,and in shell as well as invisible to the human eye defects such as aflatoxin.

METKEY Peanut CCD Color Sorter Advantage:

A: Free direct the installation and operation of the equipment and train operators for customer.

B: Safe and reliable, efficient and energy saving, easy operating.

C: In time with English operating instruction program.

D: Timely, professionally

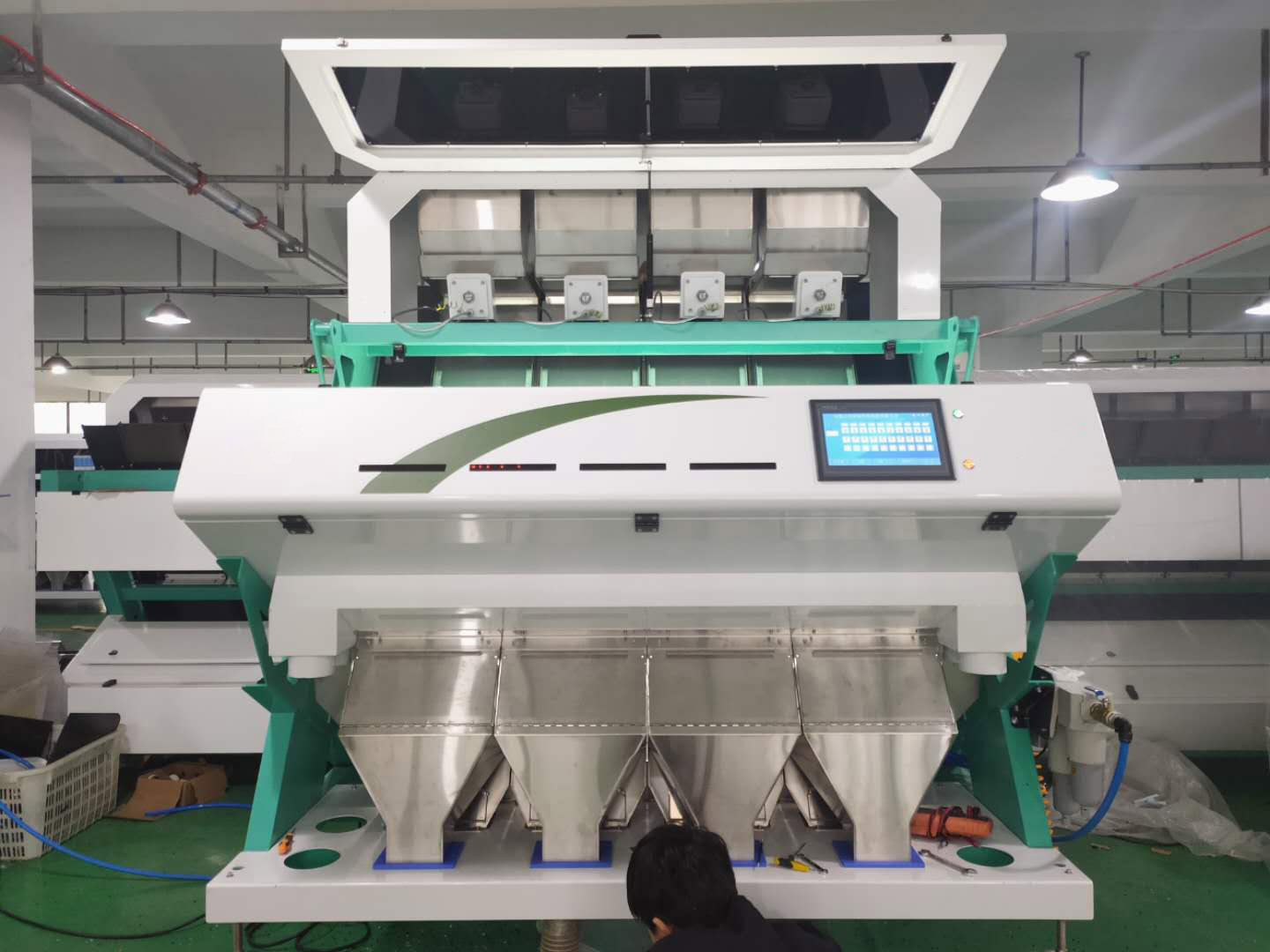

Technical Parameters:

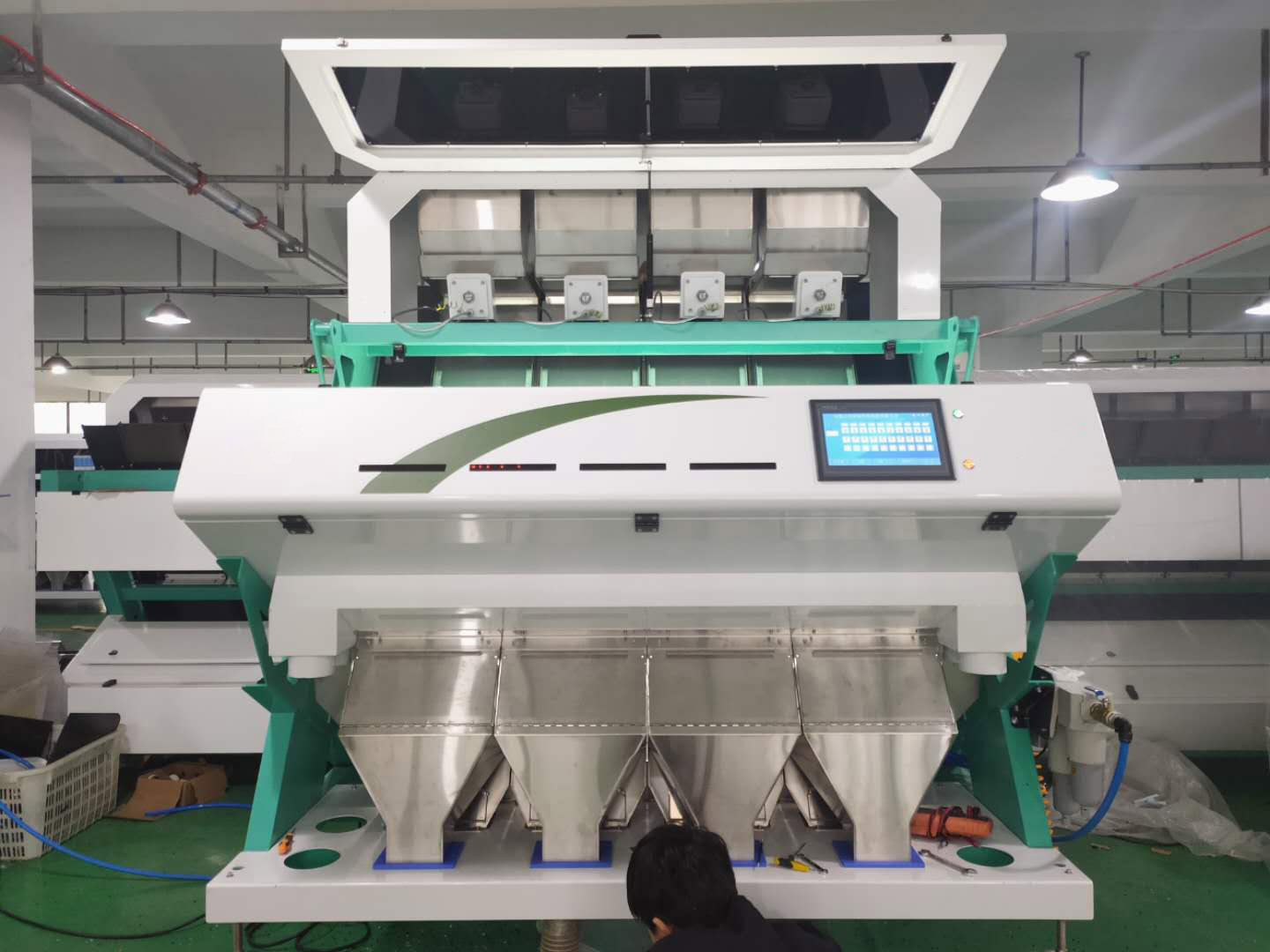

RGB full color tri-chromatic CCD image acquisition system. High camera resolution 5340 pixel identifying tiny defects up to 0.01mm2. High quality ejector with 5-10 billion ejections life low air consumption. Most unique intelligent LED with cold shadowless light source and super long life span, high lighting efficiency. Strong industry-grade digitization processor, image acquisition and processing in high speed, consistency of signal path and signal reliability is secured. International high-end full-color line scan technology, DSP+FPGA processing the international forefront of technology, combining a variety of colors and shapes model complex algorithms, to provide "color selection shape selected" function for different materials.

|

MODEL

|

MKNCS-256

|

|

Chutes/Channels

|

4/256

|

|

Throughput(t/h)

|

2-3t/h

|

|

Sorting Accuracy

|

≥99.99%

|

|

Power

|

2.3kw

|

|

Power Voltage

|

180-240V/50Hz

|

|

Air Source Pressure

|

0.6-0.8Mpa

|

|

Air Consumption

|

<2.4M3/Min

|

|

Weight

|

750kg

|

|

Dimension(L*W*H)

|

1855*1540*1852mm

|

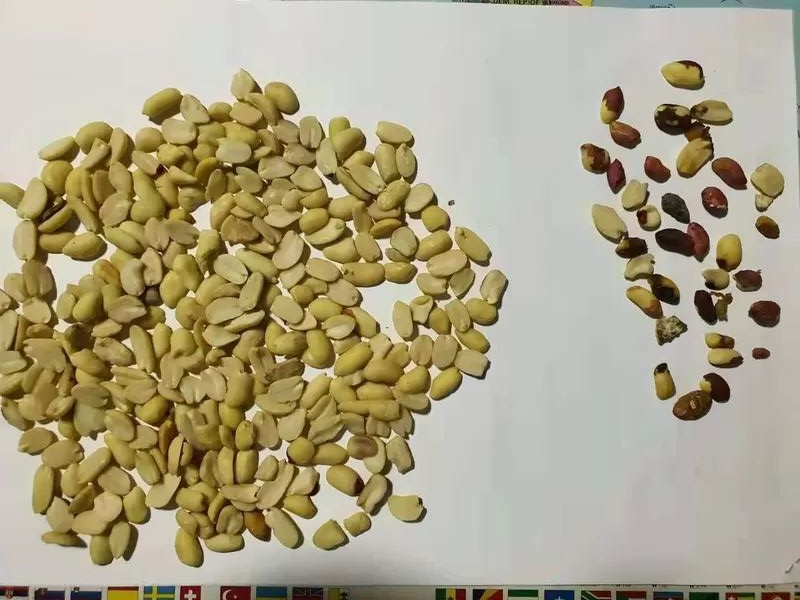

Customer Sorting Result:

Customer's Site :

One of the primary uses of an optical color sorter is to find blemishes in products, and remove unsatisfactory items from the manufacturing process. These flaws may be merely superficial, or they might indicate that a product is defective or unsafe. In a factory that produces a specific size item, for example, a defect or size variation with one of the products could cause significant problems. An optical sorter can detect the defect, and remove the improperly sized part before it is released from the factory.

Customer Service:

|

Fault phenomenon

|

Fault cause

|

Solution

|

|

Ejector leakage

|

Dust inside the ejector

|

Cyclic test of the ejector

|

|

ejector has been damaged

|

Replace ejector

|

|

Ejector fails to operate.

|

Poor contact between the plug behind ejector

and the socket

|

Re-plug, repair the poor contact position

|

|

Disconnection occurred to the valve core

|

Replace the ejector

|

|

Color sort board has been damaged

|

Replace color sort board

|

|

Ejector with small spray

volume

|

Dust inside the ejector

|

Cyclic high frequency test of the ejector

|

|

Low air pressure

|

Check pressure gauge and relevant air circuit

|

|

Material flying

|

Big difference in temperature between the

material and the material chute

|

Adjust temperature of the chute to approximate that of the material.

|

|

Dust agglomeration

|

Clean the chute with soft cloth

|

|

Chute with scratch

|

Sand papering or replace it

|

|

Frequent operation for solenoid valve

|

Wrong ejector

|

Correctly select sort mode

|

|

Position of background plate not properly set

|

Readjust background plate

|

|

No color separation

|

Low sensitivity

|

Readjust sensitivity

|

|

haven't been power on

|

Power on the solenoid valve power supply

|

|

Poor Color Separation Effect

|

Dust on the sorting glass

|

Remove dust manually or by soft cloth

|

|

Incomplete for the color sorter

|

Check or replace rubber strip

|

|

Poor Separation Effect ofComplete Machine Side

|

Incomplete or poor ash removing for the rodless cylinder

|

Adjust ash wiper and the ash wiping speed

|

|

Color sorter stops workingfrequently

|

High sensitivity

|

Readjust the sensitivity

|

|

Improper adjustment of background plate

|

Readjust the background plate

|

|

Raw material with high quantity of impurity

|

Reduce the yield

|

|

Color sorter is under pressure

|

Check pressure; readjust if the gas circuit is too far away from the sorter

|

|

Frequent pressure protection

|

Clean and open the pipeline by cleaning or replacing the filter element

|

|

Motor three-phase winding is damaged

|

Replace the motor

|

|

A.C. contactor damaged or poor contact

|

Maintain or replace A.C. Contactor

|

|

Thermorelay damaged or poor contact

|

Maintain or replace thermorelay

|

|

380V power supply phase shortage

|

Maintain charging line

|

|

Three-phase voltage imbalance

|

Adjust transformer to achieve three-phase voltagebalance

|

|

Control switch circuit damaged or with

problem

|

Check the control switch and circuit

|