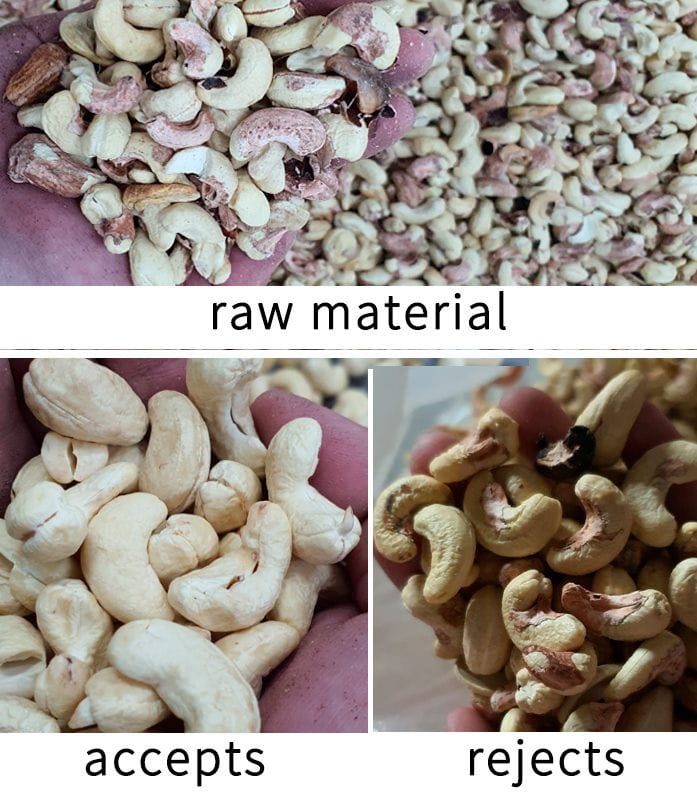

METKEY Cashew Colour Sorting Machine offer industry leading accuracy and precision to help you improve product quality and maximize product output.

The system features a high quality reject system and premium LED light system. The Nuts Sorter Color is available in a variety of configurations ranging from a single chute to a 12 chute model to meet your Nuts processing demands.

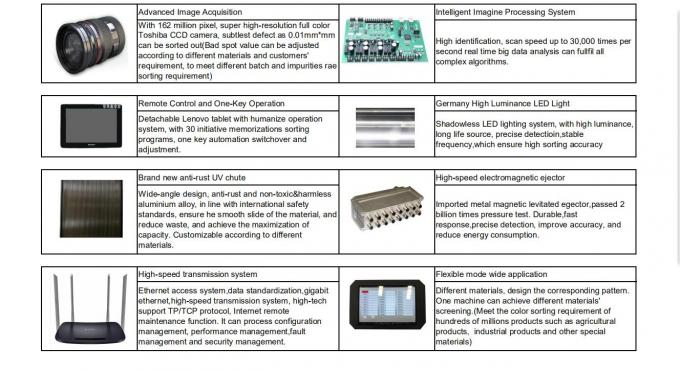

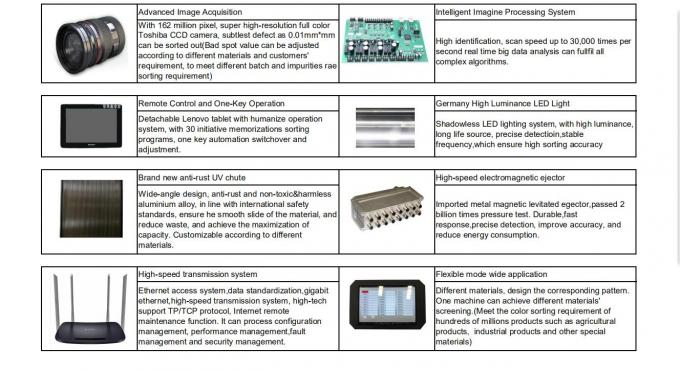

High Resolution Colour CCD Image Acquisition System – The high resolution CCD system has the sensory ability of human eye with a maximum resolution is up to 0.15mm. Coupled with a high precision lens, the system captures clear images and identifies small defects and spots on raw materials.

Flexible Configuration & Variable Light Source – The LED lighting system has a long service life, low energy consumption and consistent performance. The light source can also be customized, based on the requirements of the customer and raw materials being processed.

Dedicated Image Processing Algorithm – Raw product can be analysed based on shape and colour. For materials with complex colours, the machine sorts materials more directly and accurately by using HSV-changed colour space sorting method.

Unique Trough Configuration – The special anodising technology complies with international standards. The system can be equipped with cascade plate and narrow chute channel to meet the colour sorting for various materials.

High Quality Solenoid Valve – The high frequency ejector has a long service life and has very low air consumption, providing the highest capacity rejection output.The system is available with different sizes of solenoid valves according to the raw product being sorted.

Excellent Rejection Rate – The advanced image acquisition system features intelligent processing algorithms, a high quality nozzle system and excellent elimination rate.

Simple Easy to Use Touchscreen Interface – The graphical interface is easy to use and learn for both technicians and line operators.

Cashew Colour Sorting Machine Technical Parameter

|

Model

|

6SXZ-68

|

6SXZ-136

|

6SXZ-272

|

6SXZ-408

|

6SXZ-612

|

6SXZ-680

|

|

Output(kg/h)

|

<500

|

<1000

|

<2000

|

<3000

|

<4000

|

<5000

|

|

Sorting Accuracy(%)

|

≥99

|

≥99

|

≥99

|

≥99

|

≥99

|

≥99

|

|

Voltage (v/Hz)

|

220V 50HZ

|

220V 50HZ

|

220V 50HZ

|

220V 50HZ

|

220V 50HZ

|

220V 50HZ

|

|

Power Supply(Kw)

|

1.0-1.3

|

1.4-1.8

|

2.5-2.9

|

4.8-5.2

|

4.8-5.2

|

8.5-10.9

|

|

Pressure(Mpa)

|

0.4-0.6

|

0.5-0.7

|

0.6-0.8

|

0.6-0.8

|

0.6-0.8

|

0.6-0.8

|

|

Air Consumption(L/min)

|

<1000

|

<1800

|

<3200

|

<4800

|

<4800

|

<6100

|

|

Weight(Kg)

|

260

|

440

|

820

|

1180

|

1620

|

2200

|

|

Dimension(mm)

|

950*1510*1428

|

1290*1510*1770

|

2010*1530*2100

|

2680*1530*2100

|

3710*1530*2100

|

4200*1530*2250

|

Cashew Colour Sorting Machine Working Principle

1. Raw Material are put into the machine from its feeding hopper on the top.

2. Vibrated by vibration device and sliding along material chute into the zone of observation in sorting chamber

through sensor and background plate .

3. Under the effect of light source, CCD sensor receives compound light from materials being sorted.

4. According to the light intensity and color changes, make the system produce output signal and drive solenoid

valve to work ,ejecting the discolor grain to defect chamber and good materials continue to fall into the finished

goods chamber.

Product advantages

1. Linear array CCD adopt full-color sorting technique, high resolution for full color, High speed sorting recognition is more exquisite.

2. Blend in Shape recognition technique,more precise to make a grade to the rice and grain.

3. Visible full color light spectral distribution, free to adjust the spectral region

4. It can be suitable to sort a variety of grains, industrial products, other particles and sheet material through choose different sloping chute.

5. High resolution imaging technology,take the pictures to collect the images of sorted products,

it can be defined sorting for thousands of materials and 100,000 colors, truly achieve wide use color sorting.

6. Each group can independently and simultaneously process multi-tasking and multi-mode color sorting,

multi, anti-election and multi-color simultaneously.

7. High Brightness,long-life LED light can satify to different products and color,and needn't to change LED light.

8. Powerful software platform, easy to lear and know, simple to operate.