Up-and-down design without screw conveyor, lowered grain crack rate, trouble-free and saving power.

Large drying area, thin multi-channel drying layer, makes drying efficiency and uniform.

Automatic drying monitoring system, temperature and moisture dynamic display, fault reminder, simple operation, make the operation management more convenient.

Equipped with imported grain moisture tester, real-time accurate detection of the current moisture value of grain.

Heating by multifunctional hot air furnace, uses rice husk, straw, wood and other fuels, makes low operating costs;

Strongly remove impurity, dryer with strongly removal function efficiently dry and remove impurity;

The inner heat exhaust air duct is automatically cleaned by air flow, grain dust is discharged with the grain, not stored in air duct.

According to the level of moisture and the customer's drying needs, set multistage drying temperature automatically, to achieve uniform, energy saving, fast drying.

The most durable axis and blades with reinforcement in industry, combines with the control by frequency conversion type allocating axis.

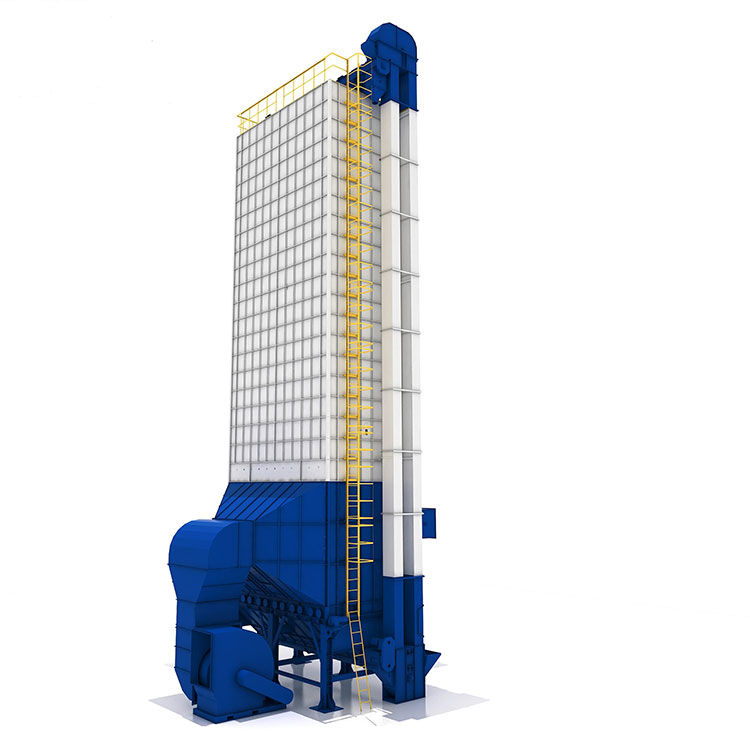

Our Large Capacity Paddy Rice Dryer Batch Cycle Paddy Dryer Advantages

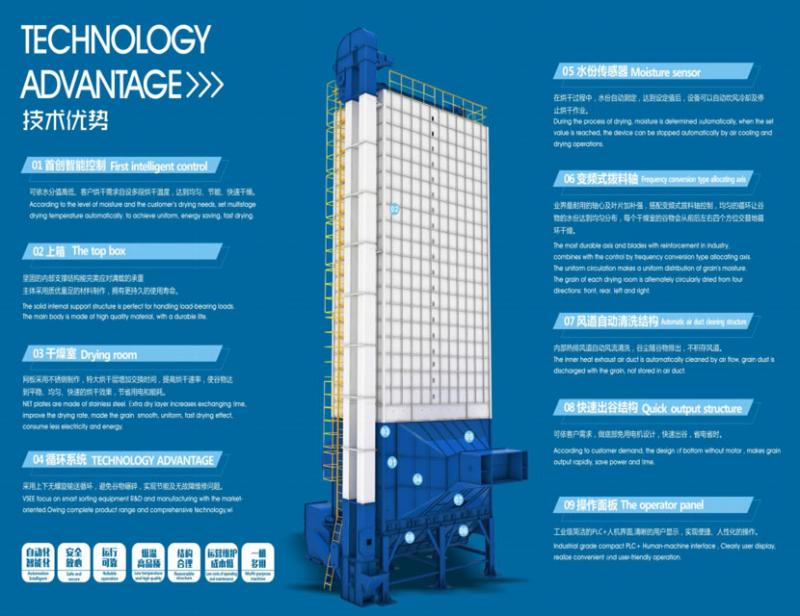

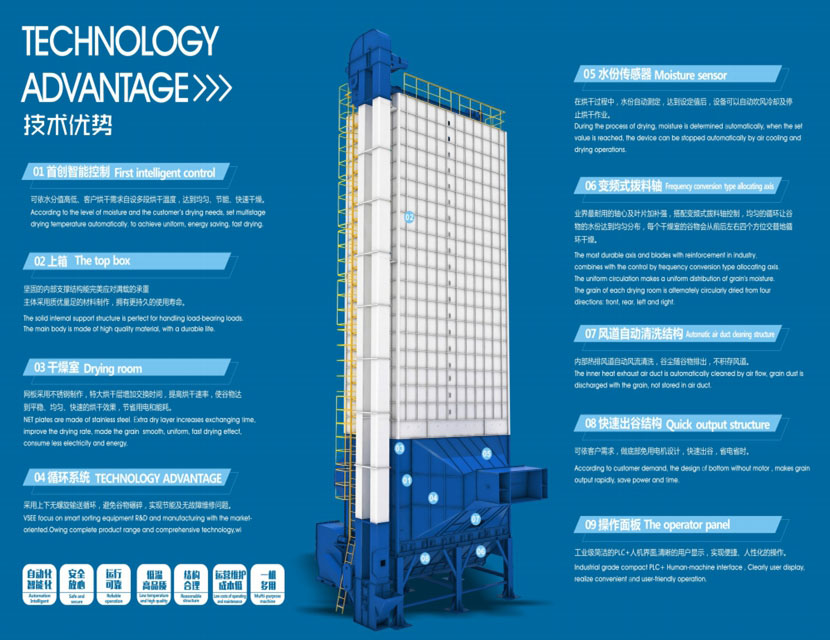

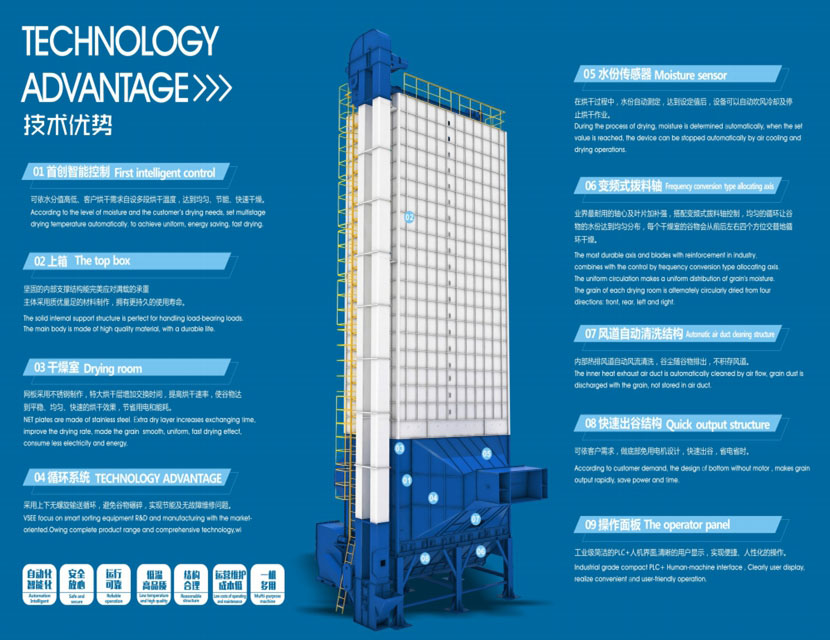

1.Intelligent control

According to the level of moisture and the customer’s drying needs, set multistage drying temperature automatically, to achieve uniform, energy saving, fast drying.

2.The top box

The solid internal support structure is perfect for handling load-bearing loads. The main body is made of high quality material, with a durable life.

3.Drying room

NET plates are made of stainless steel. Extra dry layer increases exchanging time, improve the drying rate, made the grain smooth, uniform, fast drying effect, consume less electricity and energy.

4.Circulating system

The use of up and down without screw elevator to avoid grain crushing, to achieve energy-saving and trouble-free maintenance problems.

5.Moisture sensor

During the process of drying, moisture is determined automatically, when the set value is reached, the device can be stopped automatically by air cooling and drying operations.

6.Frequency conversion type allocating axis

It adopts durable shaft and blade to reinforce, and is equipped with variable frequency control shaft control. The uniform circulation allows the moisture of the grain to be evenly distributed. The grain of each drying chamber will be alternately circulated and dried from the front, rear, left and right directions.

7.Automatic air duct cleaning structure

The internal hot exhaust air duct is automatically cleaned, and the dust is discharged with the grain, and no air duct is accumulated.

8.Quick output structure

According to customer demand, the design of bottom without motor, makes grain output rapidly, save power and time.

9.The operator panel

Simple PLC and human-machine interface, clear user display, convenient and user-friendly operation.

Large Capacity Paddy Rice Dryer Batch Cycle Paddy Dryer Show

METKEY take technology as the support, and take the market as the guidance. Focus on drying equipment research and development, manufacturing, complete product range and comprehensive technology. Our dryer have series 10T,15T,20T,30T,40T,50T,80T,100T,130T,150T etc. Our drying furnace have series 5L-30, 5L-60, 5L-1300, 5L-1500, 5L-2000 five efficient indirect furnace. These are suitable for the drying of cereal, such as rice, wheat, grain, corn, cottonseed and seed etc, to ensures that the moisture content of rice, wheat and seed is higher than national storage standard.

Large Capacity Paddy Rice Dryer Batch Cycle Paddy Dryer Customers Case