METKEY Corn color sorter use CCD optical imaging of grain of corn with mildew and black corn and corn stalk of grass and other impurities removed, after a color selection of maize quality assurance.

Broken Corn

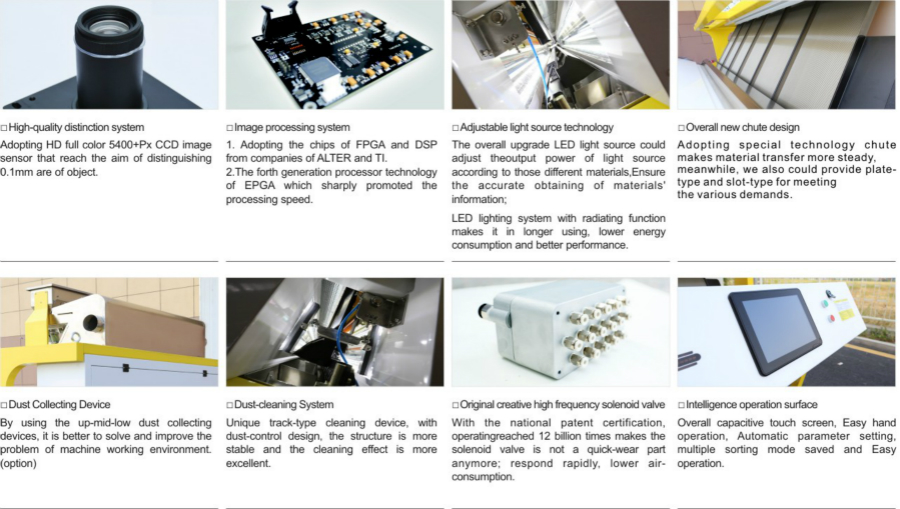

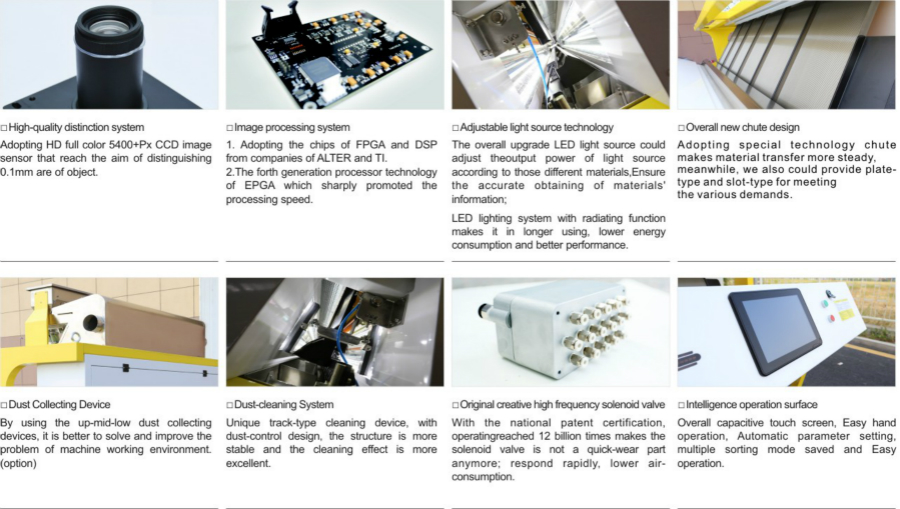

It separates grain seeds based on their sizes, and it can pick out the full seeds with 99.99% accuracy.

Impurities

It recognizes the foreign impurities by color and removes them with a fast ejector.

Moldy Corn

5700px high-revolution cameras can find out the minimum Mildew down to 0.01mm2.

5700px high-revolution cameras can find out the minimum Mildew down to 0.01mm2.

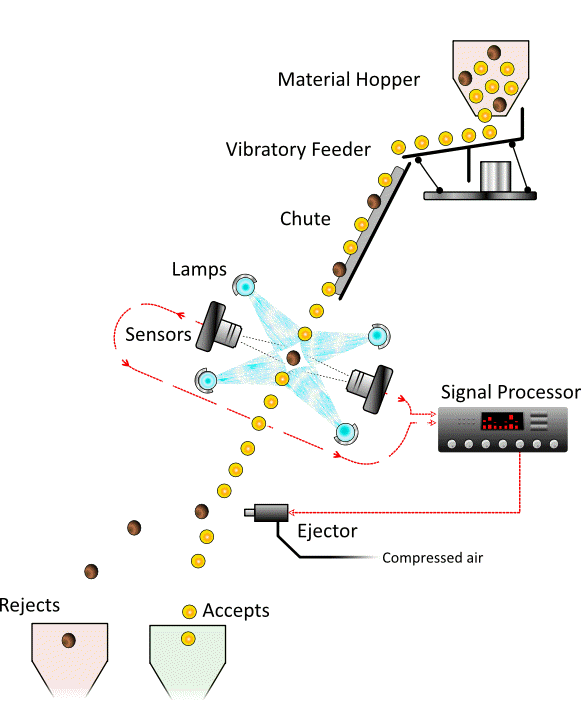

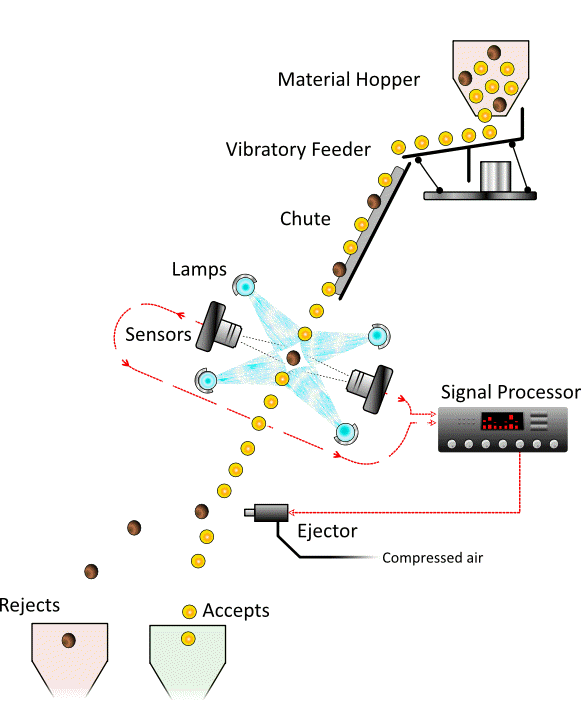

How dose corn color sorter work?

The corn color sorter can remove the moldy and black corn and corn brittle and other impurities in the raw corn grain to ensure the quality of the corn after color sorting. The impurity and defective products in raw corn grains mainly come from two sources. On the one hand, due to the promotion of agricultural mechanization, corn is mixed with some impurities and other impurities during threshing; on the other hand, corn is prone to deterioration such as mildew due to improper storage after storage. This brings about raw material quality problems during subsequent processing, so when reprocessing corn, it is necessary to remove defective products and impurities to ensure the quality of raw materials.

Corn sorting has become an inevitable process in grain processing, and the corn color sorter is a processing machine that realizes the grain sorting process. The birth of the corn color sorter can save a lot of manpower, material resources and financial resources for the grain sorting process, and bring huge benefits to the grain processing enterprises. The corn color sorter is a high-tech comprehensive technology integrating light, machine, electricity and pneumatics. It is an essential food processing equipment to realize the mechanization and automation of the grain refining process.

Corn Sorting Example

Factors influencing the use effect of corn color sorter

Corn color sorting is a process that uses CCD optical imaging technology to screen heterochromatic particles and impurities in corn. After the corn material arrives at the processing location, the output per unit time must be determined. The output is inversely proportional to the accuracy of the color sorter, that is, the greater the output per unit time, the worse the color sorting effect. In order to solve the problem of output and color sorting accuracy, the color sorting channel of the color sorter can be added to solve the problem. Our color sorters are available from single-channel mini color sorters to 12-channel color sorters. Meet the needs of different people.

Removal of the yield factor and the impurity rate is also one of the key factors that affect the color sorting effect. The impurity content is the proportion of heterochromatic particles and impurities in the corn raw grain. The impurity content in the corn material directly affects the color sorting accuracy of the corn color sorter. The higher the impurity rate, the lower the color sorting accuracy, and the worse the effect. Therefore, before starting work, set the relevant parameters such as the working mode of the color sorter according to the impurity content and output of the corn material. After the parameters are set, the selected corn is loaded into the feed hopper of the color sorter through the lifting machine. At this time, the corn is fed from the feed hopper through the vibrating feeder to the chute channel. The rice grains are arranged in the chute channel to adjust the speed to form a single layer of corn flow with uniform speed and slide out of the chute channel and fall into the detection area of the CCD lens. The main control system of the color sorter analyzes and judges the rice flow according to the data collected by the CCD lens, and uses the high-speed jet valve to blow out the rice flow from the defective products in the rice flow and enter the defective product hopper. After color sorting, high-quality corn materials will be sent to the next process for processing, and defective products will be stored separately for processing.

Basic mechanical structure of corn color sorter

The main components of the corn color sorter are: feed hopper, vibrating feeder, chute slide, light source, background plate, CCD detection lens, discharge bin and air nozzle, etc.

Feeding system

It is composed of feed hopper, vibrating feeder and chute slide. The corn material to be sorted enters the vibrating feeder from the hopper, and the material is automatically arranged into a row of continuous current slender bundles through the vibration and guiding mechanism, and after being accelerated through the trough, it falls to the detection area of the photoelectric sorting at a constant speed. In order to ensure that the material is clearly presented in the optical sorting and spraying area.

In addition to the function of providing raw grains to be selected for the color sorter, the feeding system can also realize the control of the output of the color sorter. The control of the output per unit time of the color sorter can be achieved by adjusting the flow control board of the feed hopper and the vibration of the vibrating hopper. Due to the large corn grains, it will inevitably be bounced after falling from the vibrating feeder to the chute channel, which will cause the corn to appear crowded and piled up when rolling in the channel, causing misjudgment by the CCD lens. Therefore, a shock-proof cover made of shock-absorbing material should be added above the passage to weaken the beating of corn.

Photoelectric system

The photoelectric system is the core part of the color sorter, which is mainly composed of light source, background board, CCD lens and related auxiliary devices. The light source provides stable and uniform illumination for the tested material and the background board. The CCD lens converts the reflected light of the measured material in the detection area (the detection area is a sealed matte dark box, which aims to prevent stray light from entering the CCD lens and affecting the accuracy) into an electrical signal. The background board provides a reference signal for the electronic control system, and its reflective characteristics are basically equivalent to those of qualified products, but are quite different from the rejected objects.

The adjustment of the hopper flow control board and the vibration of the vibrating hopper can realize the control of the output per unit time of the color sorter. Due to the large corn grains, it will inevitably be bounced after falling from the vibrating feeder to the chute channel, which will cause the corn to appear crowded and piled up when rolling in the channel, causing misjudgment by the CCD lens. Therefore, a shock-proof cover made of shock-absorbing material should be added above the passage to weaken the beating of corn.

Sorting system

The sorting system consists of the discharge bin, jet valve, air compressor and air filter purifier and other accessories. Since the kinetic energy of the corn material is large after being sprayed by the high-speed nozzle, the space of the discharge bin should be large enough and there should be shock absorption measures at the contact part of the material and the discharge bin. Prevent rice from entering the detection area of the CCD lens by rebounding after hitting in the discharge bin, causing accidental hitting. Experiments have proved that the nozzle interval width and the number of nozzles per unit length are one of the key factors affecting the accuracy of the color sorter. The cross-sectional area of the nozzle should be gradually reduced to achieve the purpose of compressed air, and a high-speed jet group valve should be equipped to ensure that the valve can be effectively opened and closed when the impurity content is high, preventing the occurrence of exposure.

Sweeping system

The sweeping system is composed of air cylinders, glass wipers and other components. Because corn will produce dust and other impurities that are easy to adhere to the glass during the color sorting process. Once too much dust and impurities adhere to the window glass, the photoelectric system for sorting and detecting materials through the window glass will easily produce chain reactions such as false detections. It affects the accuracy of color sorting and the output ratio of color sorting, and it causes frequent operation of the air nozzle, reducing the life of the nozzle and the control system, and even burning the nozzle control system. The glass wiper is installed on the cylinder, and the master control system controls the cylinder valve switch to push the cylinder piston to slide according to the preset time to achieve the effect of regularly cleaning the dust and impurities on the glass.

Operating system

A large-screen, wide-view, color touch operation platform is adopted, and multiple color selection modes are preset for customers. And establish a friendly man-machine interface, which can be adjusted conveniently and quickly according to the specific conditions of corn materials.

The optical sorter can sort fresh and frozen corn. It can detect and remove discolouration, pests, fruit shells, calves, foreign objects, etc. The corn enters the corn color sorter from the top hopper, which can be processed in large batches. Through the vibration of the vibrator device, the corn slides down the channel accelerate down into the observation area of the sorting room and pass between the sensor and the background plate. Under the action of the light source, according to the intensity of the light and the color change, the system generates an output signal to drive the solenoid valve to blow out particles of different colors into the waste cavity of the receiving hopper, and the well-selected materials continue to fall to the finished product cavity of the receiving hopper In order to achieve the purpose of selecting others. The Color sorting machine sorts imperfect corn, stones, mouldy kernels, black paste and other impurities, with a net selection rate of 99%, effectively eliminating corn inferior products, and the selected corn is of good quality. 53.88 million pixels, high-definition and precise identification of materials, one-key intelligent operation, easy-to-use intuitive touch screen, and better sorting effect.